Therrno-Magnetic

Choke:

If choke will not heat

properly, check for broken heater wire, high-

resistance connections or broken lead wires to the

bimetal and heater assembly. With the element at

room temperature, check the heater resistance with

an ohmmeter. The resistance should be about 30.6 to

37.4

ohms for a

12

volt system.

If the heater is

defective, replace it with a new one. When the start

button is engaged, the solenoid should cause the

spring-loaded armature to contact the solenoid core.

If this does not occur, check for broken lead wires or a

defective solenoid coil. There must be slack in the

lead wires between the choke body and the bimetal

and heater assembly. The solenoid coil resistance

should be

2.09

to 2.31 ohms in a 12 volt system.

When replacing the cover on the thermostat and

heater assembly, be certain that the choke heater

lead wires have been correctly installed in the choke

housing. improper replacement of the lead wires can

cause the choke assembly to malfunction.

The wires enter the choke assembly through a small

notch that

is

cut in the edge of the housing.

A

cover

holds the wires in place and prevents movement

when tightened. When properly installed, the lead

wires will hang freely under the bimetal coil when the

choke is in either the open or closed position. The

end of the heater wire sleeve should be located from

118

inch inside the choke housing to flush with the

inside wall.

When assembling the thermo-magnetic choke, the

bimetal and heater assembly is connected as follows:

1.

Lead tagged G‘goes to ground terminal on coil

2. Lead tagged

H

goes to either

H1

terminal on

solenoid.

solenoid core.

GASOLINE CARBURETOR

The gasoline carburetor is a horizontal draft type. It

consists of three major sections: the bowl and float,

idle circuit, and load circuit.

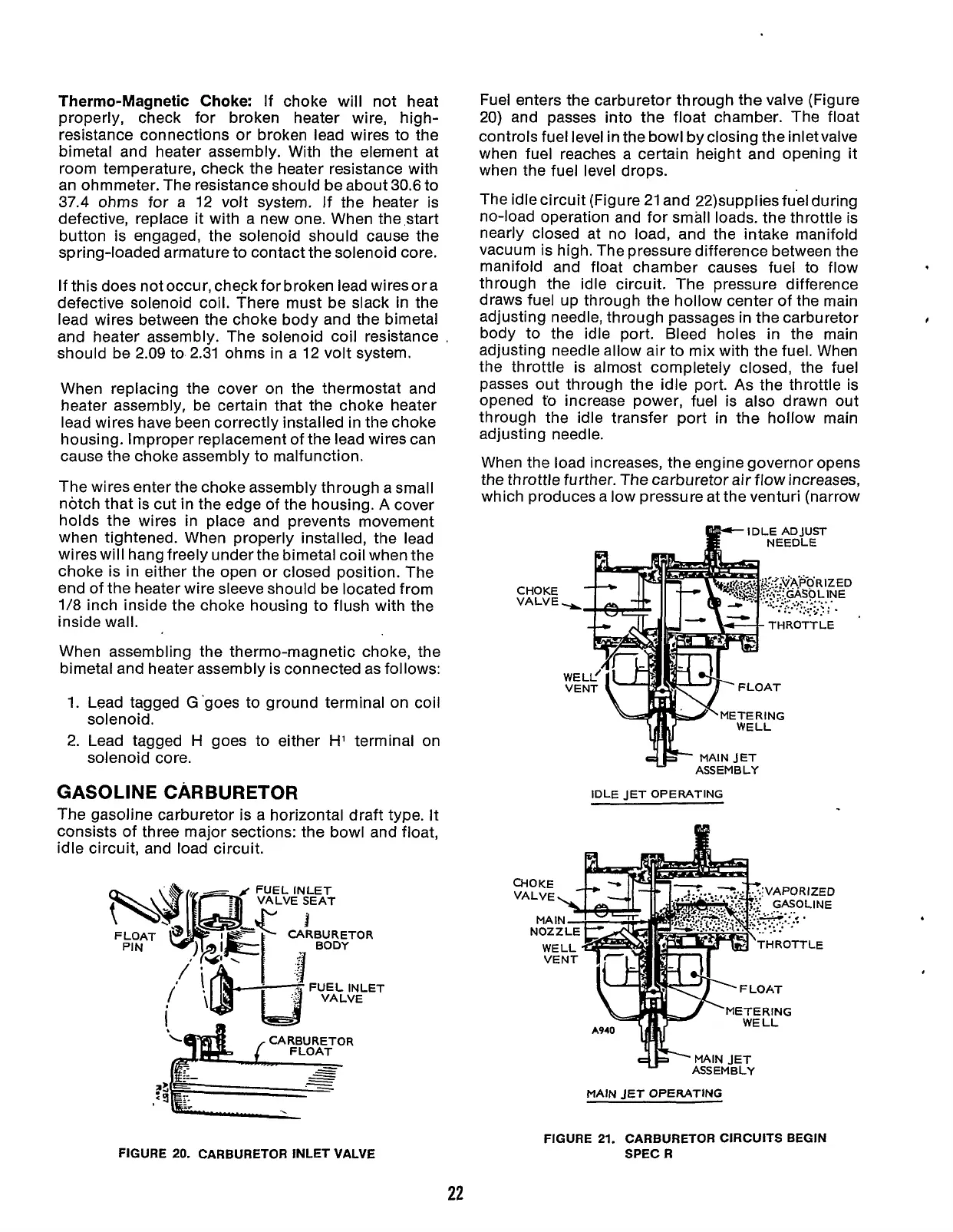

Fuel enters the carburetor through the valve (Figure

20) and passes into the float chamber. The float

controls fuel level in the bowl by closing the inlet valve

when fuel reaches a certain height and opening it

when the fuel level drops.

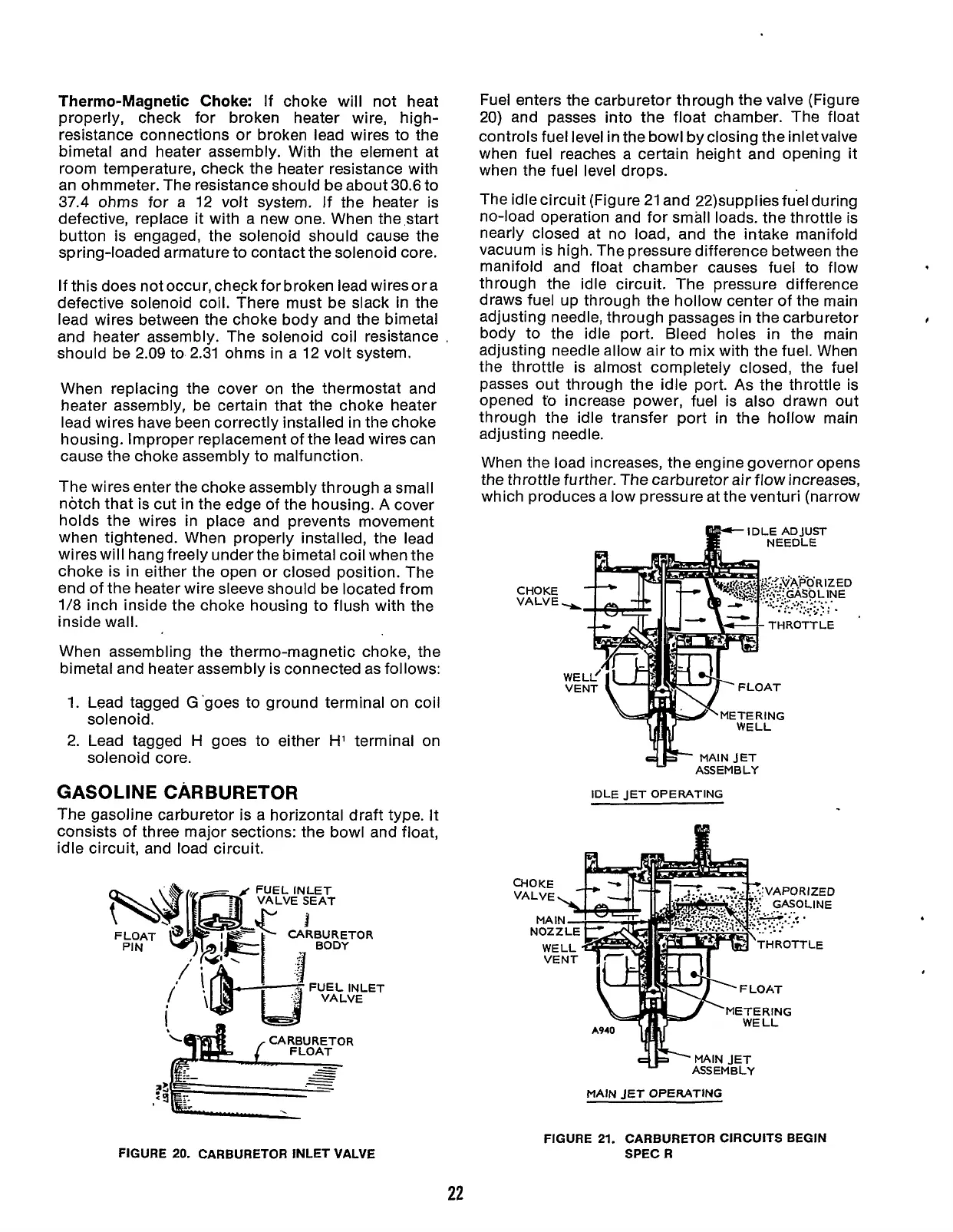

The idle circuit (Figure 21 and 22)suppliesfuel during

no-load operation and for small loads. the throttle is

nearly closed at no load, and the intake manifold

vacuum is high. The pressure difference between the

manifold and float chamber causes fuel to flow

through the idle circuit. The pressure difference

draws fuel up through the hollow center of the main

adjusting needle, through passages in the carburetor

body to the idle port. Bleed holes

in

the main

adjusting needle allow air to mix with the fuel. When

the throttle is almost completely closed, the fuel

passes out through the idle port.

As

the throttle is

opened

to

increase power, fuel is also drawn out

through the idle transfer port in the hollow main

adjusting needle.

When the load increases, the engine governor opens

the throttle further. The carburetor air flow increases,

which produces a low pressure at the venturi (narrow

I

CHOKE

VALVE

IDLE ADJUST

IDLE

JET

OPERATING

M

MAIN

JET

OPERATING

FIGURE

20.

CARBURETOR INLET VALVE

22

FIGURE

21.

CARBURETOR CIRCUITS BEGIN

SPEC

R

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...