Page 30

Trouble Shooting

illuminate after being

2. Electrical connectors are not fastened to positioner.

1. Confirm 24V DC power supply.

2. Tighten electrical connecters to the positioner.

1. Pilot pressure is not present.

2. Pilot air supply is not connected to positioner

1. Check that pilot air supply is properly

connected.

2. Connect pilot air supply to positioner housing.

open.

1. Pilot air supply is less than required.

2. Air leakage at pneumatic connections.

1. Verify that pilot air supply meets the minimum

pressure required to actuate the specific angle

seat valve model number

. Refer to values on

actuator housing.

2. Tighten the pilot supply and actuator

connections on the positioner. Tighten actuator

connection on actuator housing.

right up to stop (at

1. Pilot pressure is too low.

2. Positioner is not adjusted correctly.

1. Increase pilot supply to required value on

actuator housing.

2. Readjust position sensor.

operation (constant set

point signal) the

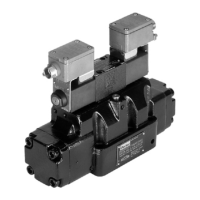

positioner internal

solenoid valves continue

1. Leak in connection from positioner to actuator.

2. Leak in actuator.

1. Find leak and correct.

2. Consult factory.

solenoid valves are not

1. Faulty solenoid valve connections (internal).

2. Contamination (particles) in the (internal) solenoid

2. Consult factory.

Valve positions not

reached correctly.

1. Positioner is not adjusted correctly.

reach setpoint

1. Value of LIM STROKE or DEAD BAND are too

small.

1. Adjust LIM STROKE and DEAD BAND values

until steady state is achieved.

Loading...

Loading...