EN | Operating manual Maintenance and repair of the dryer

40 WVM 45 -1450

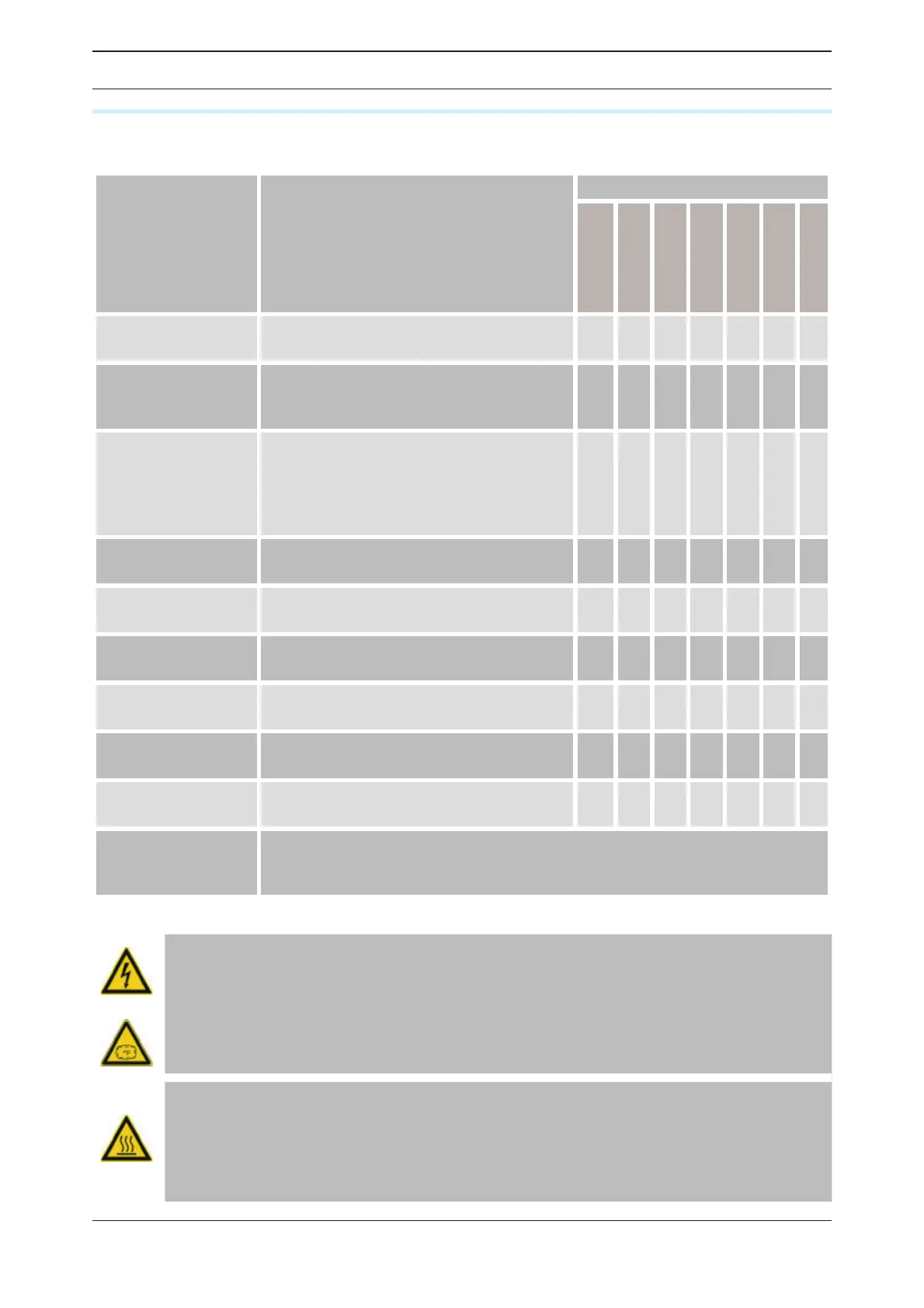

Regular maintenance taskse

The table below shows an overview of the regular maintenance tasks. The individual tasks

are described in detail on the following pages.

Component Maintenance task Maintenance interval

daily

monthly

Six-monthly

annually

every 2 years

every 4 years

see page

Dryer Complete visual inspection and

function test.

•

41

Heater Inspect intake opening for regenera-

tion air.

(obstructions)

•

41

Electrical panel Check that the screw connections

and clamps are secured; tighten if

necessary.

(Reduce maintenance intervals in the

event of heavy vibrations.)

•

42

Silencer Renew silencer every year and after

desiccant renewal.

••

42

Control air lter Inspect control air lter and clean or

replace, if necessary.

•

42

Dewpoint trans-

mitter

Renew

•

42

Vacuum pump Inspect bearing and replace, if nec-

essary

•

44

Dessicant sieve Check Dessicant sieve for contami-

nation and clean, if necessary.

•

44

Desiccant Check desiccant for contamination

and replace, if necessary.

•

44

Preliminary and

after lter (op-

tional)

Please refer to the manuals of the installed lters for details on the

maintenance tasks to perform.

When carrying out any maintenance work, please observe the following safety instructions:

Danger!

Working on the dryer when it is switched on and under pressure entails a subs-

tantial risk of injury.

Before starting maintenance work, always shut down the dryer as described on

page 37 !

Risk of injury posed by hot surfaces!

The dryer’s surfaces may remain very hot even after it is switched off. Do not

touch hot surfaces!

Wait until the surfaces have cooled down suffi ciently before starting work on

the dryer.

Loading...

Loading...