GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

6

3 Safety information

3.1 General safety information

Operation, installation and maintenance may only be carried out by qualified personnel. The responsible

operator must be authorised in writing.

It is forbidden to transport people or to stay in the danger area of devices not designed for this purpose.

Exception: Screw jacks with safety features with corresponding intended use as described in Chapter 1.1

in the framework of the corresponding product standard.

Not suitable for use in explosive atmospheres!

Exception: Screw jacks are designed and marked as components for use in explosive-atmosphere

zones, as described in Chapter 1.2

Never reach into moving parts. Cover them or cut off access to them.

Do not remove or disable the safety devices.

The operational and safety limit switches must ensure that the lifting process is safely stopped at the end

positions.

To prevent contact with rotating/moving parts, attach protective covers (such as bellows, shaft caps) or

make those areas of the machine inaccessible.

Screw/Travelling nut must be fastened on-site or be turn-secured or equipped with the optional torsional

lock (max. screw torque according to technical documents). The construction must be able to bear the

screw torque securely.

Ball thread spindles and multi-geared trapezoidal thread spindles are not self-locking. An appropriate brake

device needs to be integrated into the system.

In the standard version, the screw does not have any protection against unintended skimming out of the

gear box (Ba1) or against the travelling nut driving out the screw. A protection against skimming needs to be

realised either on site or by worm gear screw jacks with mechanical end stops.

No lateral forces on the screw.

3.2 ATEX safety information

The owner of a system must ensure that the explosion-risk conditions are adhered to.

On-site layer thickness from surface coatings (e.g. lacquering) max. 2 mm (explosion group IIA and IIB) and

0.2 mm at explosion group IIC

Requirements for the reliable operation is a properly lubricated screw and a lift gear box provided with

lubrication.

The affects from knocks and bumps on the screw jack is not permitted.

Dust deposits are to be removed regularly.

Connect the screw jacks with potential equalisation (earth) and check the bleeder resistance (<10

6

Ohm).

Observe the speeds and permitted drive power output specified in the technical data when operating with

rotation speed control in the potentially explosive atmospheres.

On motorized drives, monitor the motor output with output gauges or otherwise temperature monitors (e.g.

thermistors (PTC) with evaluation device). Minimum requirements according to EN 13463-6 category 2-

IPL2; cat. 3 –IPL1.

Materials used must be resistant against the media.

The operator must count or measure the load cycles or operating hours and document them.

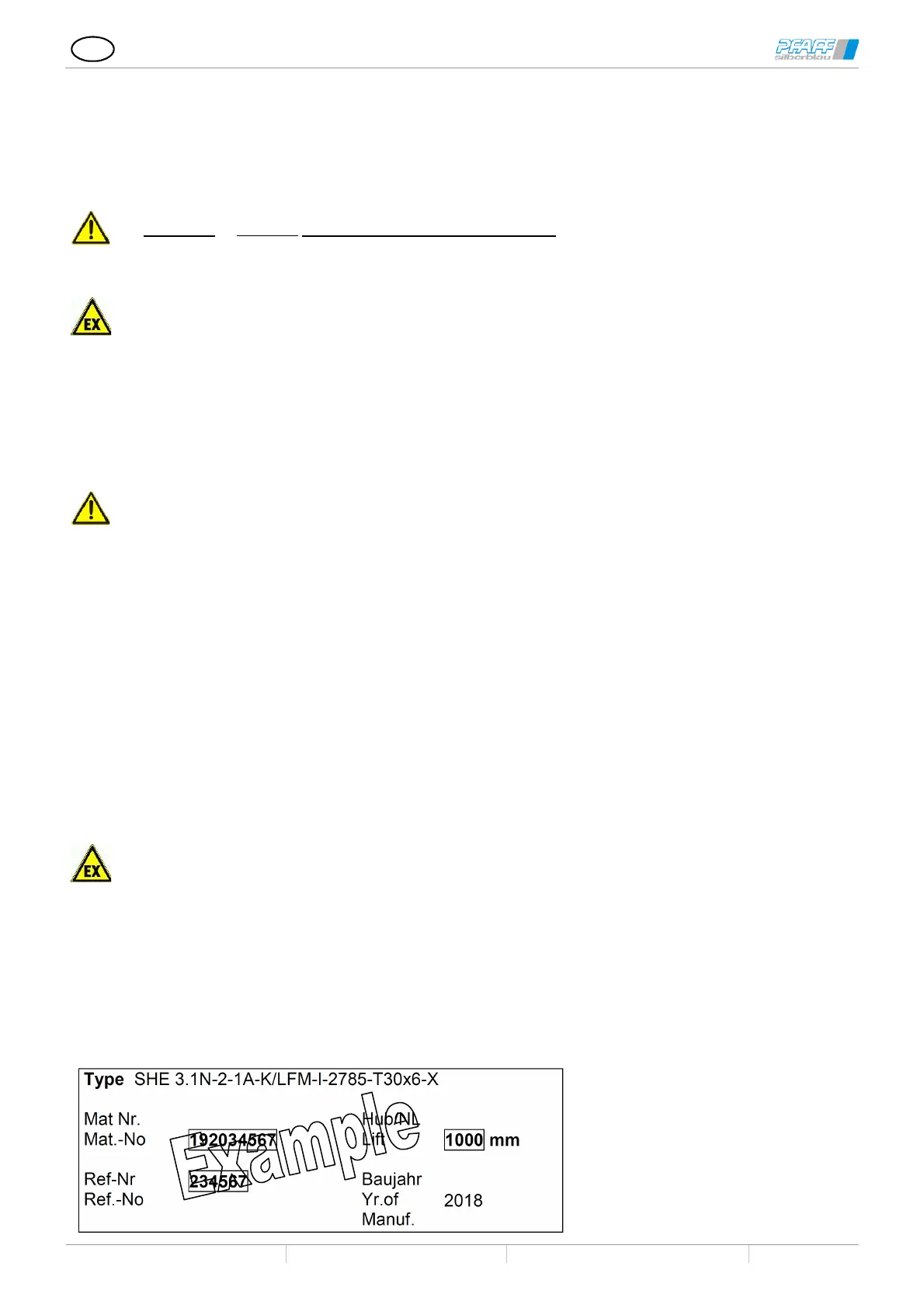

3.3 Type plate

Loading...

Loading...