Refitting the crankshaft bearings

Heat the bearings in an oil bath at around 150°C

and fit them on the crankshaft, if necessary using

a section of tube that acts on the bearing's inner

track

Specific tooling

020265Y Bearing fitting base

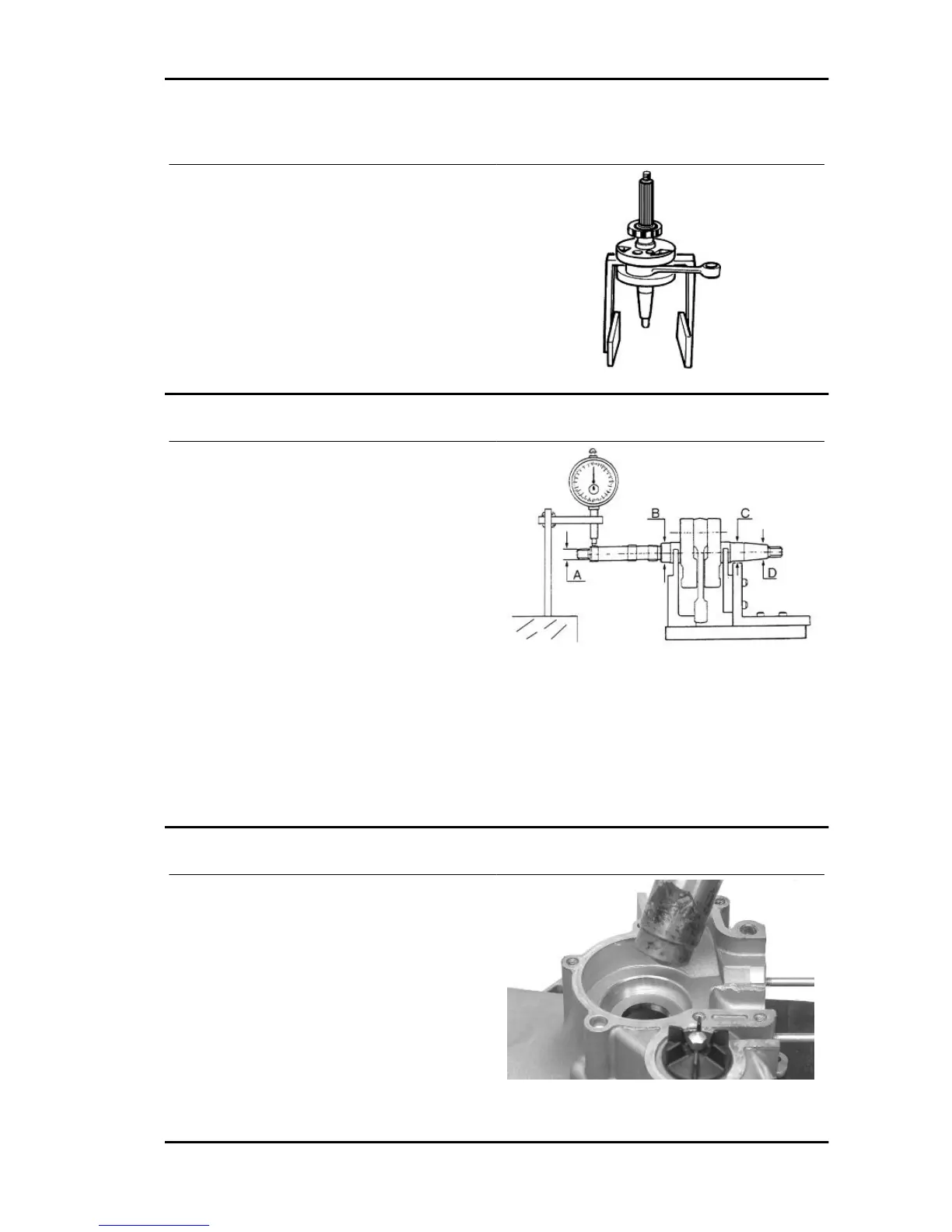

Inspecting the crankshaft alignment

With the specific tool shown check that the eccen-

tricity of the surfaces of diam. «A»-«B»-« C» are

within 0.03 mm. (reading limit on the dial gauge);

in addition, check the eccentricity of diam. «D», for

which a maximum reading of 0.02 mm is permitted.

In the case where eccentricity is not much above

prescribed levels, straighten the shaft by acting

on the counterweights with a shim or tighten them

in a clamp (with an aluminium bushing) as re-

quired..

Specific tooling

020335Y Magnetic mounting for dial gauge

020074Y Support base for checking crankshaft

alignment

Refitting the crankshaft

- Position the transmission side half crankcase on

two wooden supports

- Using a thermal gun, heat the bearing seat to

about 120°

Liberty 50 Catalyzed Engine

ENG - 85

Loading...

Loading...