4 Resistivity Measurements on Site

4.1 Influences

Influence of rebars on electrical resistivity measurements

The presence of rebars disturbs electrical resistivity measurements as they conduct current much

better than the surrounding concrete. This is particularly the case when the cover depth is less than

30 mm.

As far as possible, reinforcement bars should not be directly beneath the probe and should not

run parallel to the probe. The recommended measurement orientation is determined by the spacing of the

rebars compared with the probe spacing.

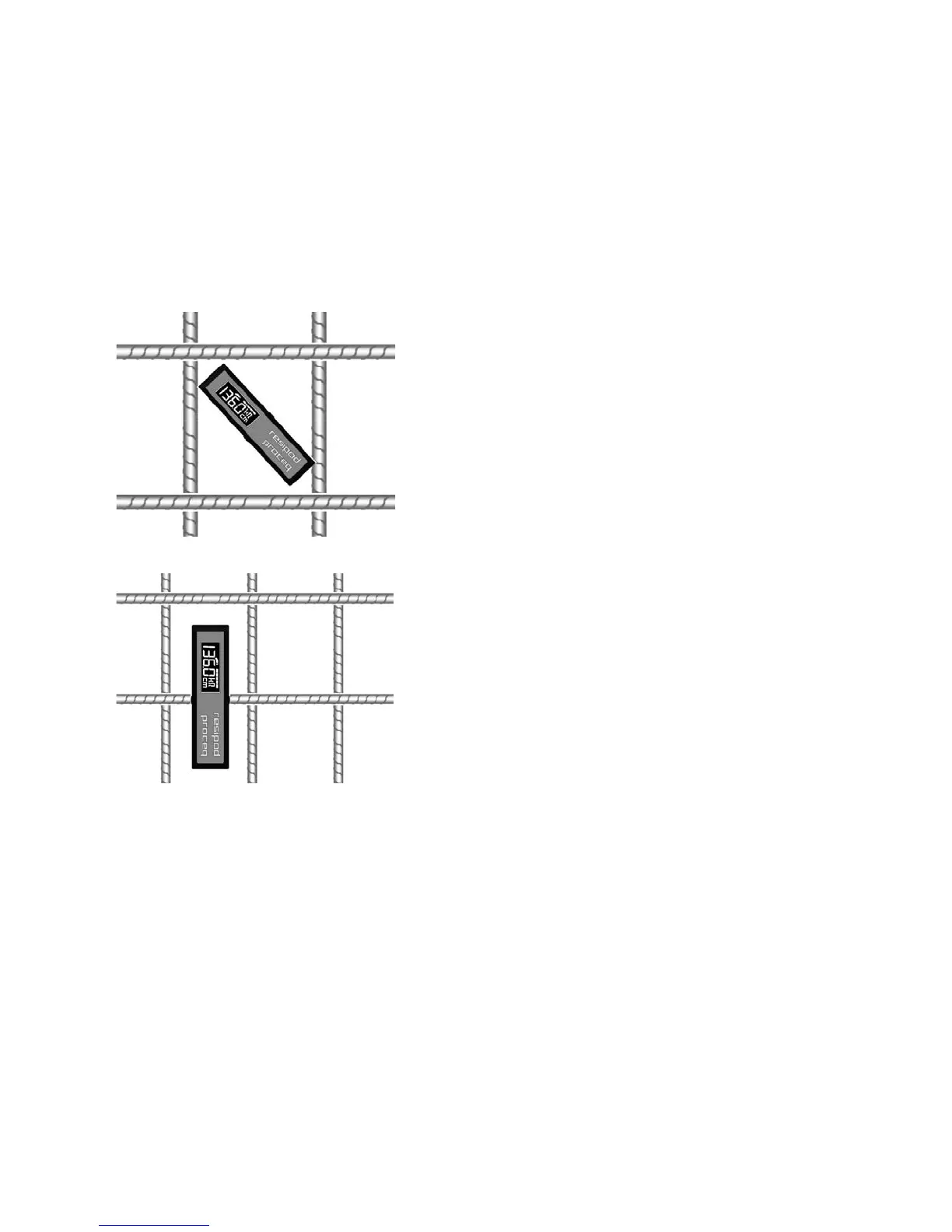

The optimum orientation is to measure diagonally to the

rebars as shown. This is possible if the probe span is

less than the rebar grid spacing.

For the Resipod 38 mm, the probe span is

38x3 = 114 mm (4.5”)

For the Resipod 50 mm, the probe span is

50x3 = 150 mm (5.9”)

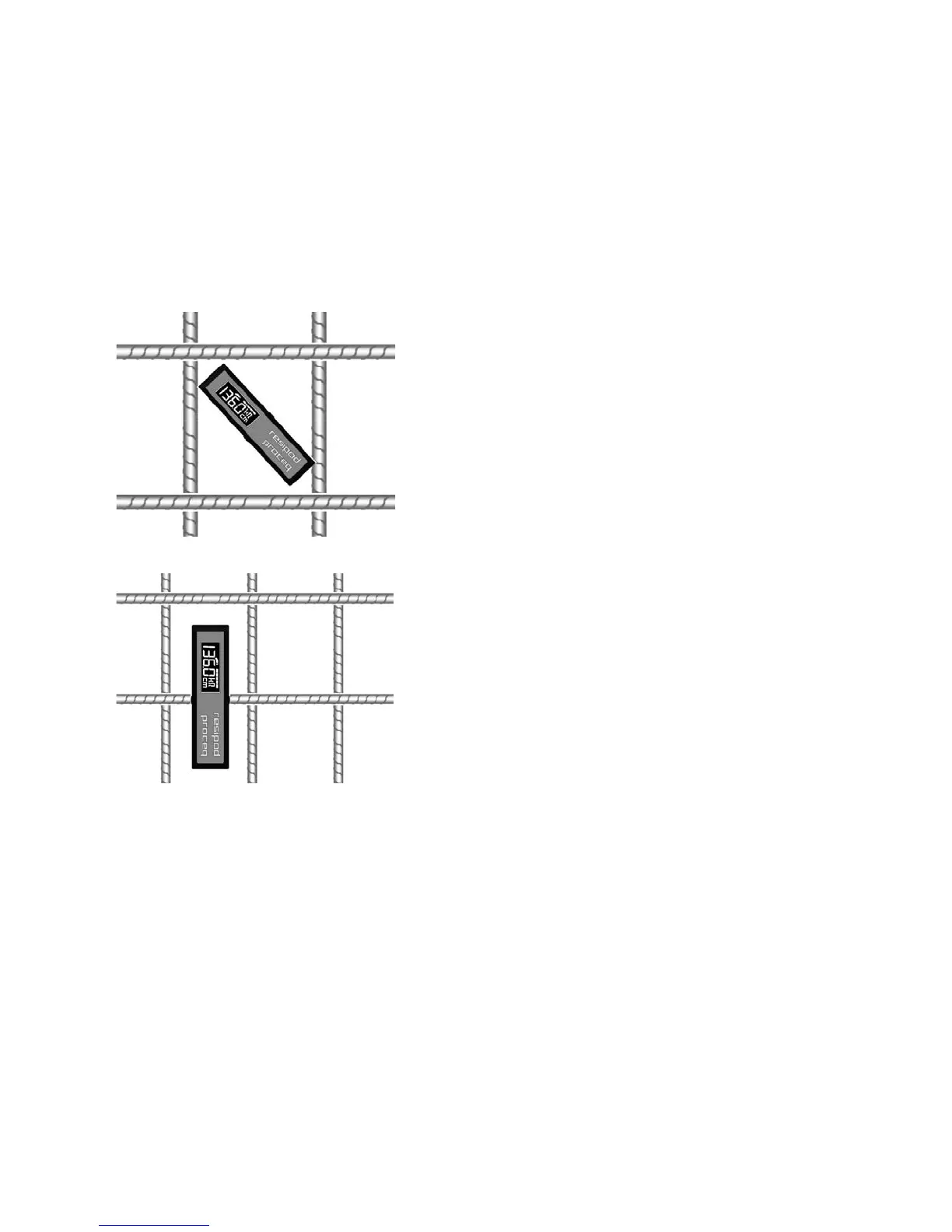

If the rebar spacing is so close that it cannot be

avoided, the influence of the steel can be minimized by

measuring perpendicular to the rebars as shown.

RILEM TC154-EMC: ELECTROCHEMICAL TECH-

NIQUES FOR MEASURING METALLIC CORROSION

recommends making 5 readings from the same location

moving the probe a few mm between each measure-

ment and taking a median from the 5 values.

Influence of aggregate size

As explained in 2.2, the current flows in the pore liquid of concrete. Ideally the probe spacing

should be larger than the maximum aggregate size as aggregate material is typically non-conduct-

ing. The variable spacing probe supplied with Resipod Geometric should be used for aggregate

sizes larger than the standard probe spacing.

Influence of temperature

The temperature of the concrete should be measured and recorded with resistivity measurements.

Resistivity decreases as the temperature increases. Reference values for resistivity measurements

are typically quoted for 20°C (68°F). Empirical studies have shown that a one degree increase in

temperature can reduce the resistivity by 3% for saturated concrete and 5% for dry concrete.

Influence of moisture content

A higher moisture content lowers the resistivity. This can be due to saturation or due to a change

in the water/cement ratio.

Loading...

Loading...