3 Measuring Resistivity with Resipod

Preparing the concrete surface

The concrete surface must not be coated with any electrically insulating coating, and it should be

clean. The rebar grid beneath the surface should be marked out with the help of a rebar locator

(e.g. Profoscope). If the concrete is completely dry it will not be possible to make a measurement

as the current is carried by ions in the pore liquid, (See 2.2). Therefore it may be necessary to wet

the surface.

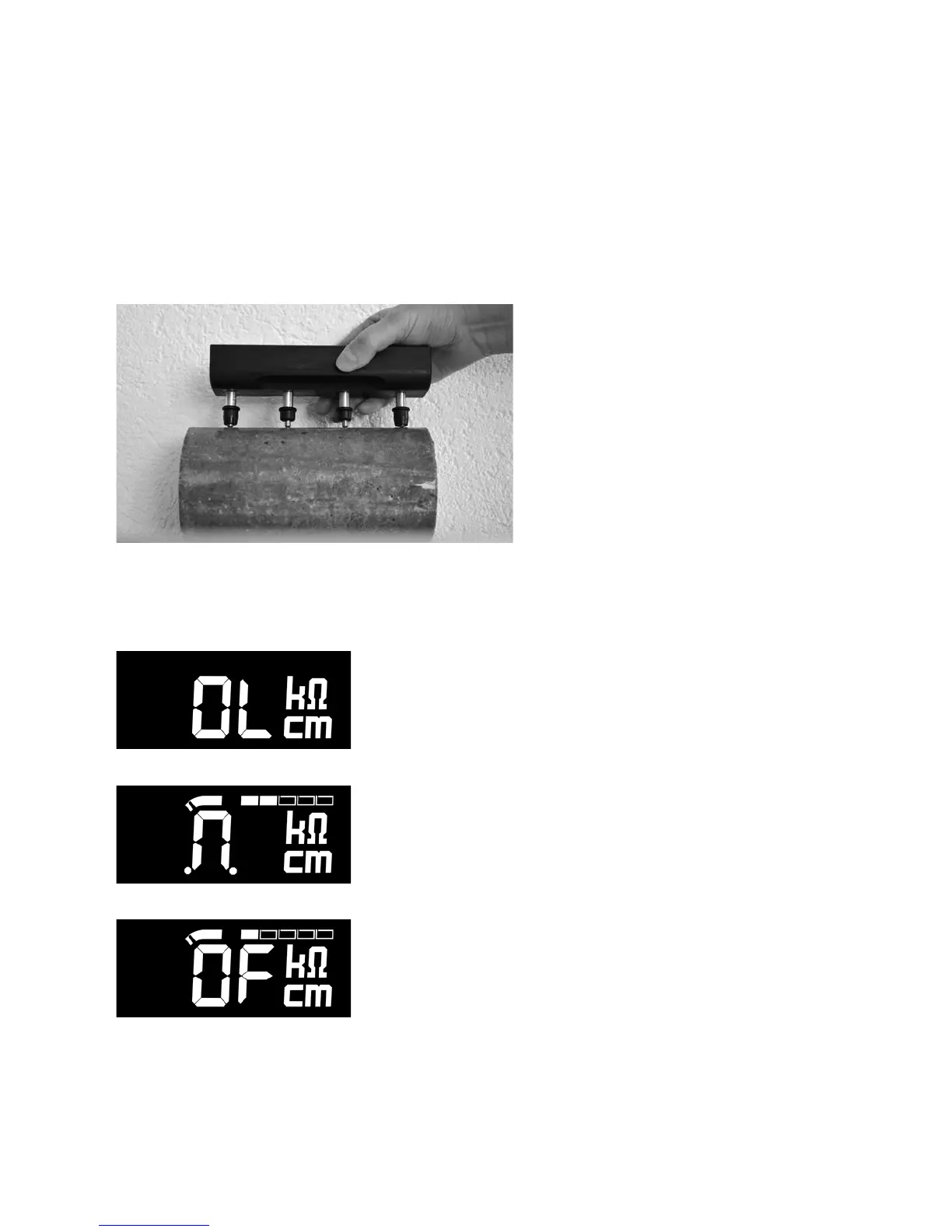

3.1 Making a Measurement

A good connection between the

instrument and the concrete surface is

the most important factor for obtaining a

reliable measurement. Dip the contacts

in water several times before making a

measurement – use a shallow container

so you can press against its bottom

– this will fill the reservoirs. Press the

Resipod firmly down until the outer two

rubber caps rest on the surface to be

tested.

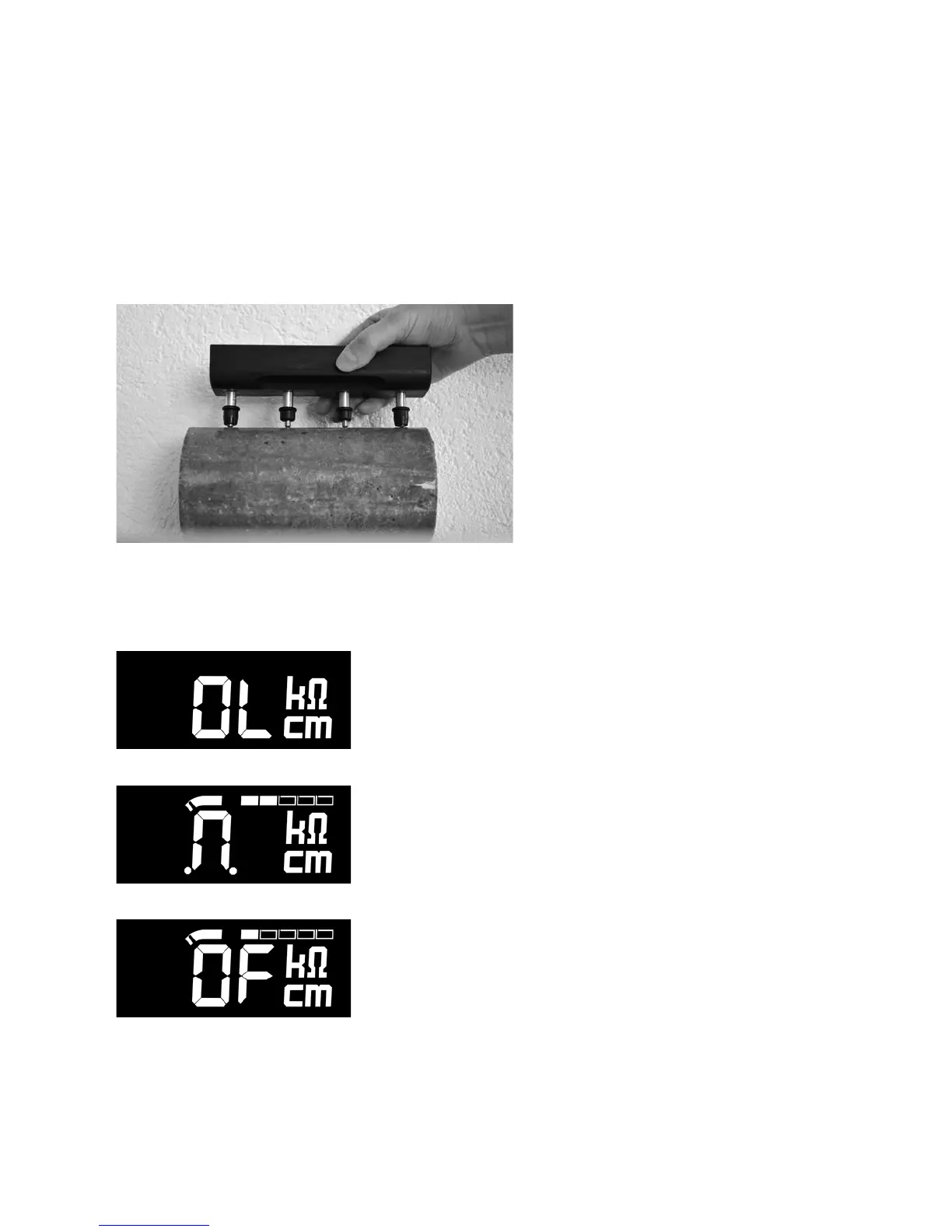

Indication of poor connection

In the case of a poor connection, the Resipod will display one of the following alerts.

“Open Line” indication

Bad connection of the two outer probes to the concrete

surface. No measurement possible.

Inner two probes are not making contact.

(check for holes or dry spots on the specimen)

Or Sample resistivity <1kΩcm

Material resistivity is extremely low.

Overflow

The measured resistivity is out of range. This limit is

dependent on the spacing, but it is typically a resistivity of

>1000 kΩcm.

Contact selection

The steel probe tips are rugged and may be used to scratch away a thin layer of plaque on the

surface in order to make a better connection. The size of the contact however, means it is not

always possible to drive the full 200µA into the concrete to obtain the maximum measurement

resolution.

Loading...

Loading...