EN

BTR185 INSTALLATION AND USE MANUAL - REV009A

42

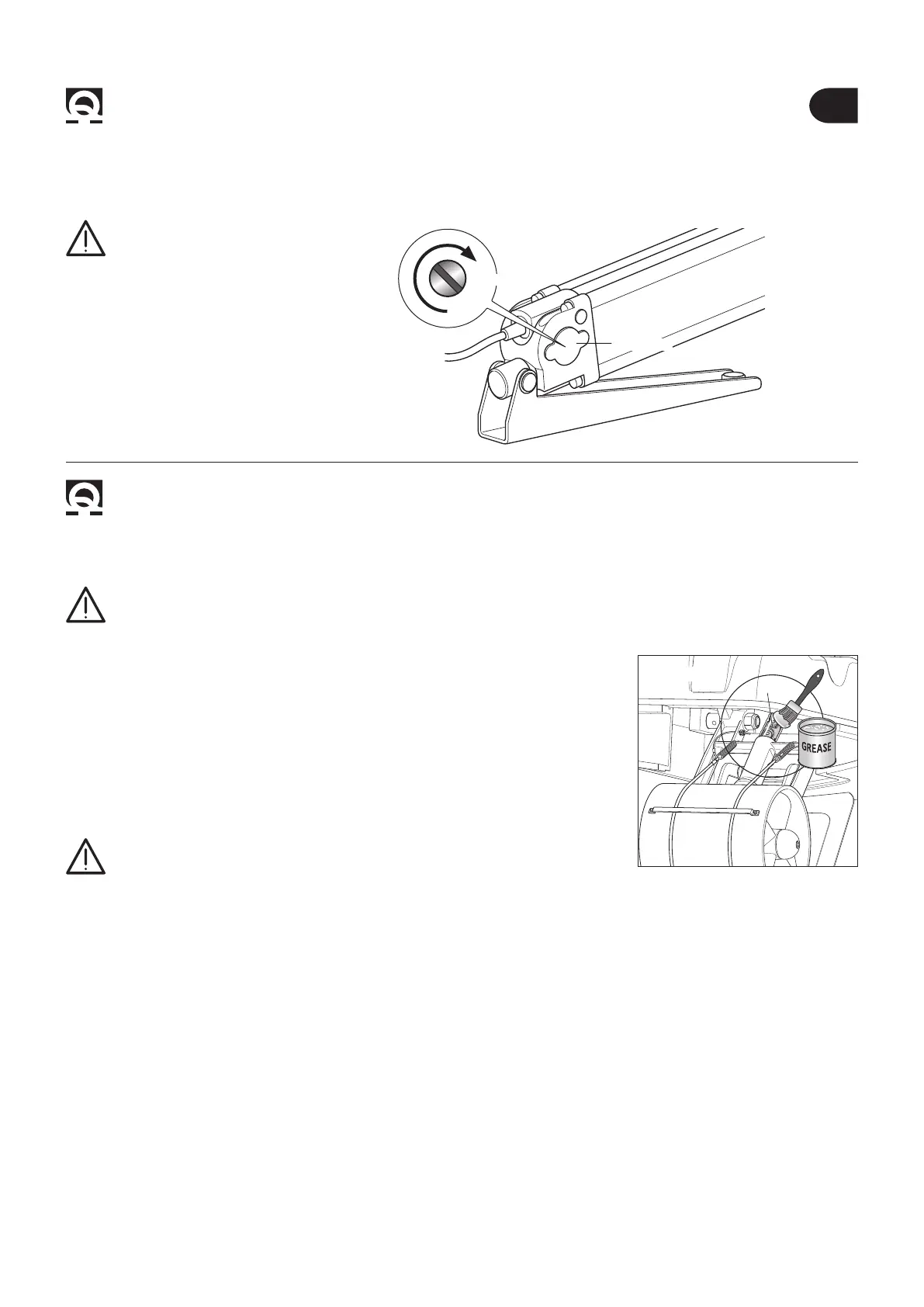

BTR185Thruster’s closing problems

WARNING: disconnect the

BTR propeller from power.

ACTUATOR

STICKER

SLOTTED SCREW

In emergency, the propeller can be locked in the closed position

On the actuator, under the sticker,

there is a slotted screw;

turn it clockwise with a screwdriver

to close the system.

Maintenance BTR185

Quick

®

Thrusters are made in materials that are resistant to the sea environment: In any case, it is indispensable to periodi-

cally remove salt deposits that form on the outer surfaces to avoid corrosions and consequent system inefciency.

WARNING: make sure that the power supply to the electric motor is not switched on when maintenance operations

are carried out.

NR. DESCRIPTION

1 SCREW

2 GROWER

3 MOTOR

4 REVERSING CONTACTOR UNIT

5 WASHER

6 SCREW

7 CARTER REVERSING

CONTACTOR

8 FASTENERS CARTER

REVERSING

CONTACTOR

9 SCREW

10 SCREW

11 FLANGE

12 CHASSIS

13 SCREW

14 WASHER

15 NUT

16 GASKET O-RING

17 O-RING

18 OIL SEAL

19 KEY

20 ACTUATOR’S LEVER

21 ACTUATOR’S PLATE

22 CABLE OUTLET

23 SCREW

24 RRC RX BOX

25 PIN

26 SPRING RING

27 ACTUATOR

28 SCREW

29 FULCRUM

30 PIN

31 ANGLE BAR

32 HINGE’S BRACKET

33 HINGE’S SHAFT

34 SCREW

35 WASHER

36 HINGE’S ARM

37 LID’S BRACKET

38 OIL SEAL

39 INTERNAL CIRCLIP

40 BEARING

41 SHAFT

42 KEY

43 EXTERNAL CIRCLIP

44A BEARING

45 SHAFT SUPPORT

46 OIL SEAL

47 EXTERNAL CIRCLIP

48 PLATE

49 DOUBLE JOINT

50 EXTERNAL CIRCLIP

51 OIL SEAL

52 NUT

53 PIN

54 PIN

55 FULCRUM

56 SCREW

57 ANODE

58 SCREW

59 CABLE-STOPPER

60 SCREW

61 NUT

62 TILTING BODY

63 PIN

64 NUT

65 LEVER

66 LEVER

67 EXTERNAL CIRCLIP

68 SCREW

69 SPRING

70 SHAFT

71 SCREW

72 GROWER

73 O-RING

74 GASKET

75 KEY

76 GEARLEG

77 PLUG

78 PROPELLER 185 R

79 PROPELLER 185 L

80 NUT

81 ANODE

82 SCREW

83 TUNNEL

84 CABLE GUIDE

85 WASHER

86 SCREW

87 SELF-LOCKING NUT

88 WASHER

89 SELF-LOCKING NUT

90 CABLE

Drawing number page 43

49

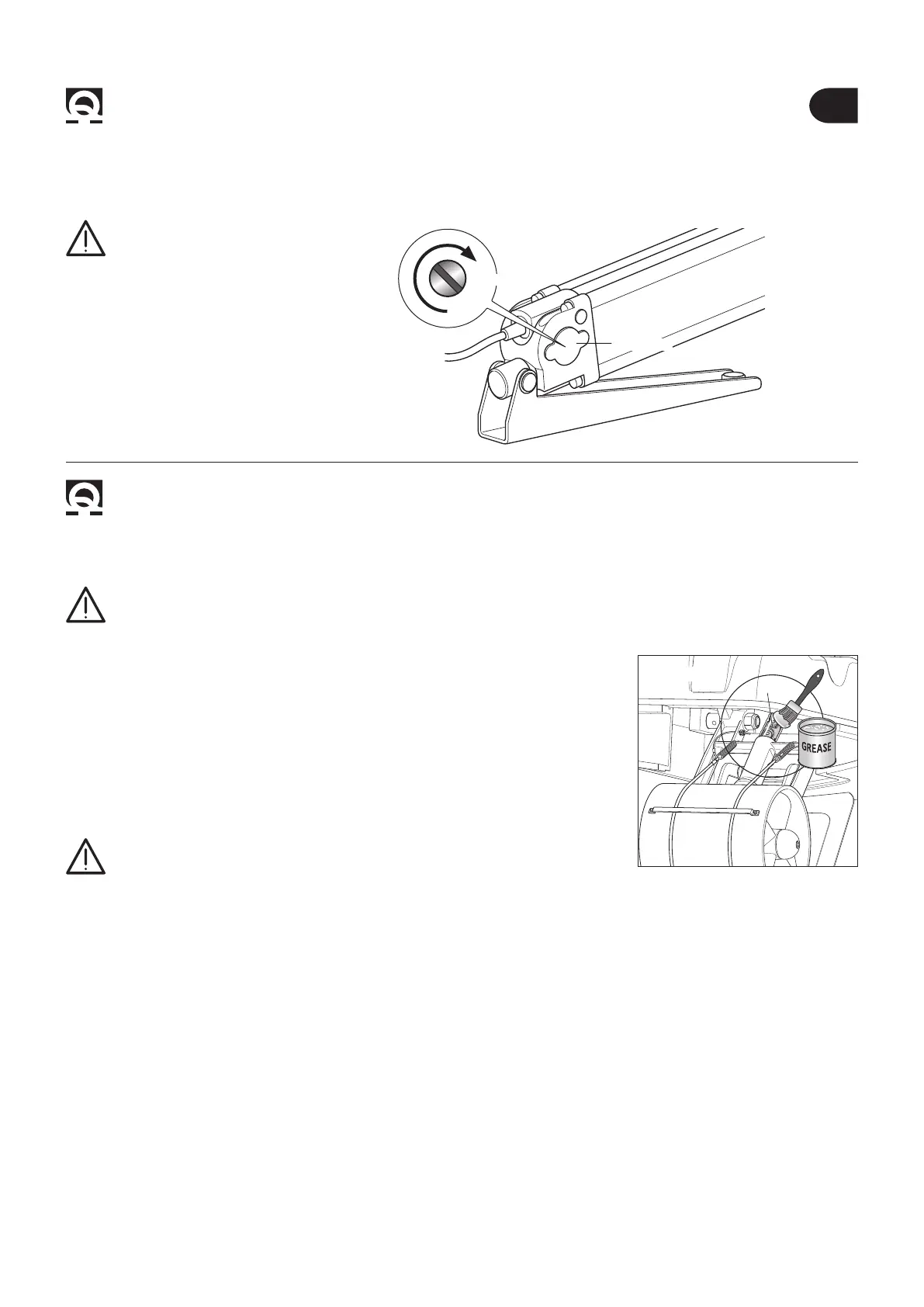

Fig. 25

Dismantle once a year, following the points below:

• Clean propellers (78 and 79), tunnel (83) and gearleg (76).

• Replace the anodes (carry out this operation more often if needed) and,

if possible, grease the double joint (49) with marine grease (g. 25).

• Replace the propellers if damaged or worn out.

• Check the tightness of all screws.

• Ensure that there is no water seepage inside.

• Check that all electrical connections are well tightened and oxide-less.

• Check that the batteries are in good conditions.

WARNING: do not paint the zinc anodes (57 and 81),

the sealings and the gearlegs’ shafts where the propellers are lodged.

Loading...

Loading...