COMBUSTION ADJUSTMENT

THE FOLLOWING BURNER

ADJUSTMENTS MUST BE MADE

AFTER 10 TO 15 MINUTES OF

OPERATION.

8. Set the draft. Remove the heat

shield and then remove the metal

plug in the burner mounting plate.

Check the draft reading over the

fire with a draft gage through the

5/16" hole located in the burner

plate. See the draft gauge section

in this manual for more

information. Adjust the barometric

damper to give the overfire draft

recommended by the manufacturer.

If no such recommendations are

available, set the overfire draft to

assure a negative pressure within

the combustion chamber (usually a

negative 0.01 to 0.02 inches water

column).

Replace the hole plug in the

burner mounting plate after these

tests have been made.

9. Check the smoke readings. After

the burner has been operating 10

minutes, make a smoke measure-

ment in the flue following the

smoke tester instructions. See the

smoke pump section in this

manual for more information. Oily

or yellow smoke spots on the filter

paper are usually a sign of un-

burned fuel, indicating very poor

combustion (and likely high emis-

sions of carbon monoxide and

unburned hydrocarbons). This

condition can sometimes be

caused by too much air, or other

factors. If this condition cannot be

corrected, major correction or

even burner replacement may be

necessary. Adjust the air shutter

and air band for a 0 to a 1 smoke

number (a trace).

10. Check the CO

2

with the Fyrite

analyzer. See Fyrite Gas Analyzer

section for methods and

procedures. Adjust the air setting

to reduce the CO

2

reading by

between 1% and 2%. Lock the air

adjustment and repeat all draft,

CO

2

, and smoke measurements to

make sure the setting has not

shifted.

COMBUSTION DIAGNOSIS

11. Check performance. A well-

matched and well-tuned burner

should be capable of operation at

a CO

2

level between 10% and

12%.

FINAL CHECKS

12. Measure the flue temperature.

See the stack thermometer

section in this manual for more

information. Operating the unit at

an excessive firing rate generates

pollutant emissions. Check for

prompt pump cutoff by observing

the flame or by checking for

smoke at shutdown. If poor cutoff

is observed, make sure all air is

purged from the pump and nozzle

line. If poor cutoff continues check

for proper cutoff pressure.

15. Check Controls. Check the

settings of all operating controls

before leaving the installation and

verify that they are in working

order.

16. Check for proper temperature rise

of the supply air. See the air

supply temperature section in this

manual for details.

17. Annual Cleanup. An overall burner

checkup and cleanup is

recommended annually. See the

annual cleanup section in this

manual for more information.

13

more heat than the heat

exchanger can utilize and results

in unnecessary heat loss up the

chimney. Other causes of

excessive heat loss are badly

sooted heat-exchanger surfaces

and excessive draft. The tempera-

ture of the flue gas provides an

indication of these heat losses.

Measure the net flue temperature

by subtracting the room air tem-

perature from the thermometer

reading. Excessive flue loss is

indicated if the net flue

temperature during steady

operation exceeds 600° F.

13. Check Ignition. Check the

operation over repeated cycles to

insure prompt ignition on starting.

14. Check pump cutoff. See pump

section for the procedure for

checking cut off pressure. Slow

pump cutoff at the end of a firing

cycle can cause smoke and other

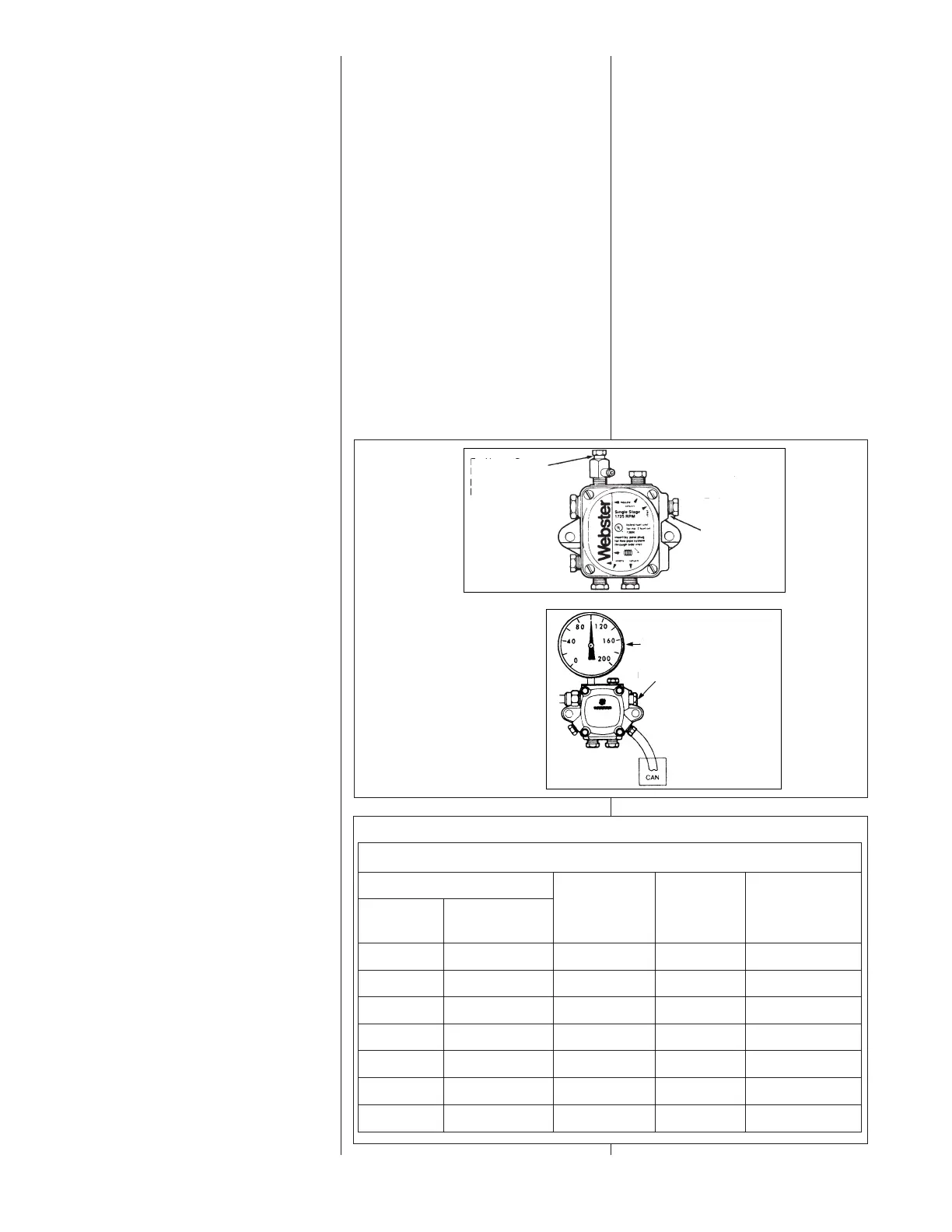

FIGURE 13

FIGURE 14

Table 11

FACTORY AIR ADJUSTMENT SETTINGS

BURNER

AIR SHUTTER

SETTING

AIR BAND

SETTING

OIL FURNACE

MODEL

BECKETT

MODEL

AFG AF42JYPWHS 10 BLANK -056

AFG AF42JYPWHS 10 BLANK -067

AFG AF42XNPWHS 10 2 -084

AFG AF42XNPWHS 10 2 -095

AFG

AFG

AFG

AF42XNPWHS

AF42JZPWHS

AF42JZPWHS

10

7

7

2

4

4

-112

-130

-150

BECKETT

DESIGNATION

For Use as Gage

Port. Remove vent

plug to install 1/49

pipe threaded gage.

To Adjust Pressure:

Insert standard

screwdriver. Turn

counterclockwise to

below pressure

desired. Turn

clockwise to set to

desired pressure.

GAGE PORT

PRESSURE

PRESSURE ADJUSTMENT

Loading...

Loading...