Install a single wall, vent connector

from flue outlet to chimney, sloping flue

pipe continuously upward (at least 1/4

inch per foot) toward chimney. The

vent connector should be the same

diameter as the flue collar of the

furnace for the entire length of run and

should not exceed 10 feet in length.

Avoid sharp turns that would create

resistance to the flow of flue gasses.

Vent connector should not extend

beyond the inside wall of the chimney

and must be firmly cemented to

masonry.

IMPORTANT: This furnace is agency

approved by UL, ULC and CSA for use

with the Tjernlund SS1-R sidewall vent

system when installed in accordance

with the installation instructions for the

SS1-R provided by Tjernlund. The

maximum vent length is 10 feet with 3

elbows when venting with the SS1-R.

This is the only option given for side

wall venting. It should be noted that

common venting with another

appliance is not an option when using

the Tjernlund SS1-R. The use of any

other type of power vent system is not

approved or recommended by the

manufacturer.

No other appliances or heating

equipment should be connected to the

vent connector servicing the furnace.

Bolt, screw and/or support joints to

avoid sag. Fasten the single-wall vent

connector to the outlet collar of the

furnace with at least two sheet metal

plumb. Tilting causes erratic damper

operation. Installation of a barometric

damper must be in accordance with the

Installation and Operation Instructions

provided with the damper.

The following standards and codes will

help to make the installation. Current

editions of these standards can be

obtained from:

American National Standards Institute,

1430 Broadway, New York, NY 10018

OIL BURNER / PRIMARY

CONTROL

Oil burner and primary control are

mounted to the furnace as a complete

assembly. Standard equipment

consists of the oil burner, primary

control and flame sensor mounted as a

single assembly to the furnace. The

heat/cool relay is mounted to the unit’s

main junction box and the flame sensor

(cadmium sulfide cell) is enclosed in

the burner housing above the blower

wheel.

The standard oil burner is equipped

with a single stage fuel pump. This

single stage fuel pump may be used in

either a one or two pipe system. If a

two pipe system is required (burner is

screws. Refer to Figure 1 for distances

to combustible materials.

DEVICES ATTACHED TO THE FLUE

OR VENT FOR THE PURPOSE OF

REDUCING HEAT LOSS UP THE

CHIMNEY HAVE NOT BEEN TESTED

AND HAVE NOT BEEN INCLUDED IN

THE DESIGN CERTIFICATION OF

THIS FURNACE. WE, THE

MANUFACTURER, CANNOT AND

WILL NOT BE RESPONSIBLE FOR

INJURY OR DAMAGE CAUSED BY

THE USE OF SUCH UNTESTED

AND/OR UNCERTIFIED DEVICES,

ACCESSORIES OR COMPONENTS.

BAROMETRIC DRAFT

CONTROL

The barometric damper (see figure 7) is

a control installed in the flue pipe to

regulate the draft in the furnace. If the

draft increases in the chimney, the

damper opens to maintain the preset

draft in the furnace. Should the draft

decrease in the chimney, the damper

will close to maintain the preset draft of

the oil furnace. A barometric damper is

supplied with each furnace and must be

installed by the following the

instructions supplied by the

manufacturer. The barometric damper

control should be installed between the

flue outlet of the furnace and the

chimney (see figure 8). The barometric

damper control should be set for proper

draft on start up after the furnace has

been operating for 10 to 15 minutes.

See Oil Burner Adjustment Procedure

Section for proper draft settings.

On start up, the furnace must be set

for field conditions with a

combustion kit for proper operation.

Note: Always use a seperate

barometric damper for each oil-fired

appliance. Install the barometric

damper with its hinge level and the face

8

TABLE 1. Metal Thickness for Galvanized Steel Pipe

Connectors

Diameter of Galvanized Minimum

Connector Sheet Thickness

(in.) (mm) Gauge No. (in.) (mm)

< 6 < 152 26 0.019 0.48

≥ 6 to ≤ 10 ≥ 152 to ≤ 254 24 0.024 0.61

> 10 to ≤ 16 > 254 to ≤ 406 22 0.029 0.74

>16 > 406 16 0.056 1.42

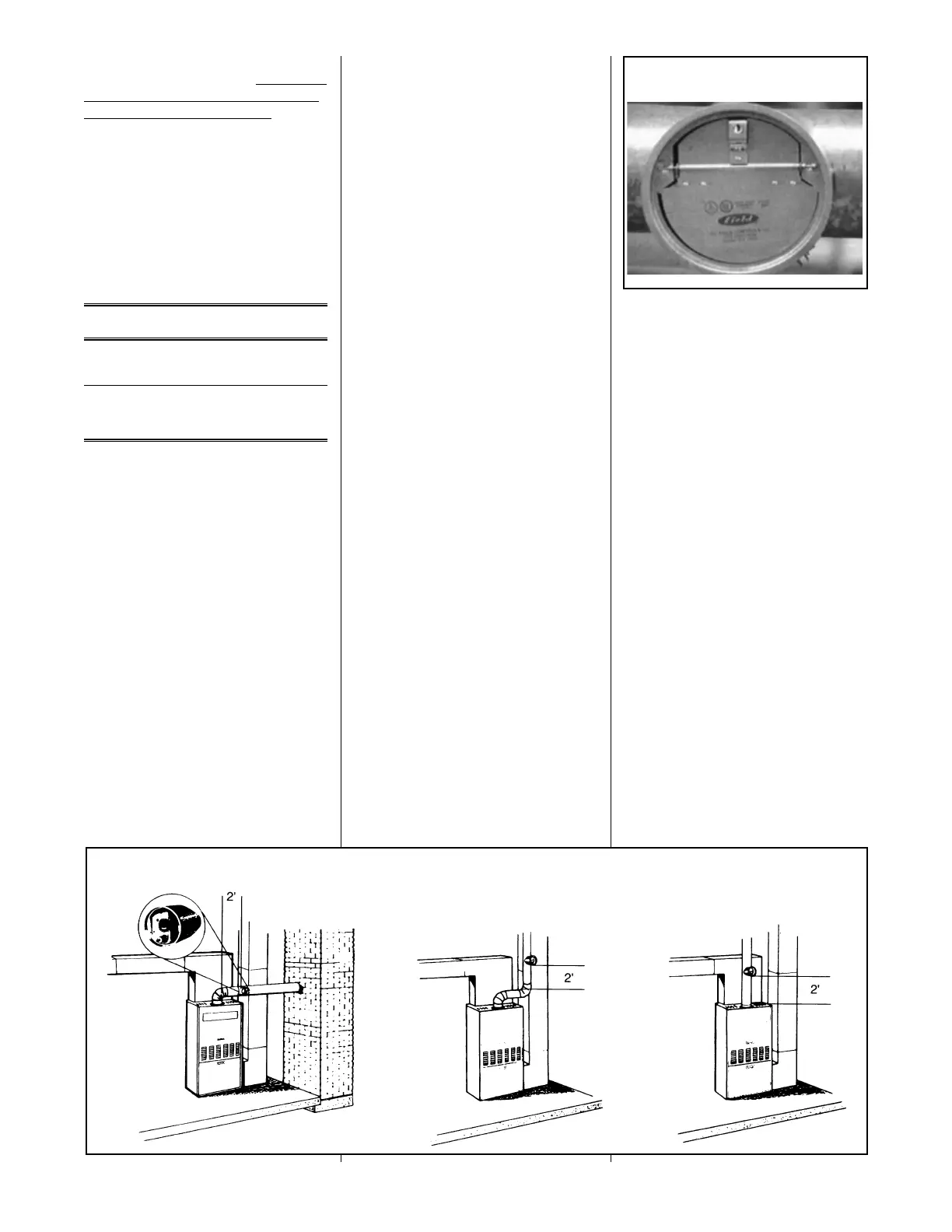

Figure 8

Recommended Barometric Damper Locations

Figure 7

Barometric Damper

Loading...

Loading...