16

SUPPLY AIR

TEMPERATURE

The temperature rise of the air through

a furnace will vary with each furnace.

For proper temperature rise of the

furnace in question, check the rating

plate on the furnace or Table 7 in this

manual.

A. Temperature rise is the

temperature difference between

the air entering and leaving the

furnace.

B. The proper way to measure the

temperature rise follows: First

open all registers and dampers to

allow proper air flow. Then allow

the furnace to operate 10 to 15

minutes before taking the

readings.

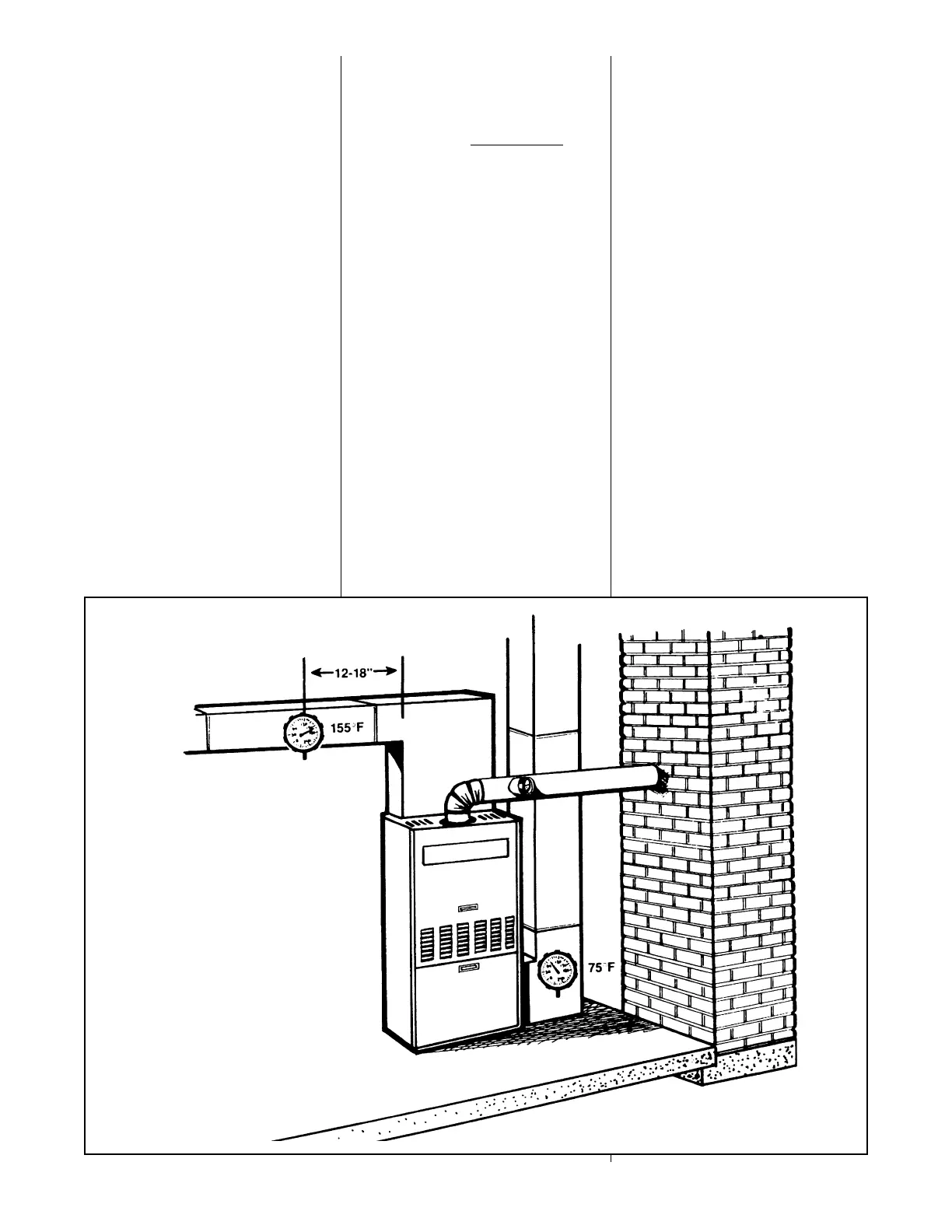

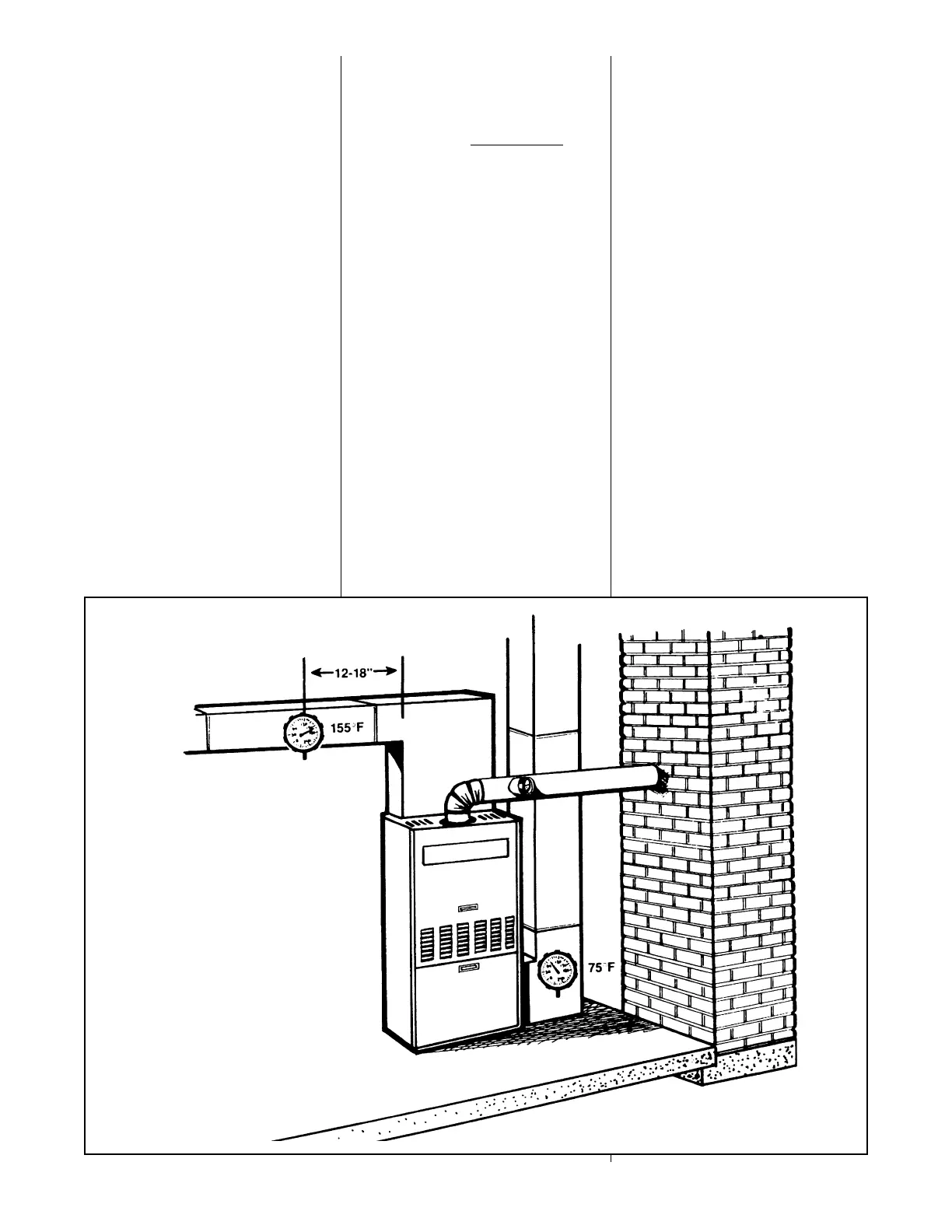

C. Use two thermometers; insert one

in the supply air duct and one in

the return air duct. Do not place a

thermometer in the supply duct

directly above the heat exchanger

as the thermometer will pick up

radiant heat from the heat ex-

changer. (See Figure 19.)

D. Calculate by subtracting the return

air temperature from the supply air

temperature.

Example

Supply air

temperature 155 degrees

Return air

temperature

75 degrees

Temperature

rise = 80 degrees

E. Compare the calculated tempera-

ture rise with the specified

temperature rise on the rating

plate.

TEMPERATURE RISE TOO

HIGH

• Check for proper fan speed

• Check static pressure on duct

system for proper air flow.

• Check proper cooling coil size.

• Check duct static pressures for

proper air flow.

• Check for proper oil pressure.

• Check nozzle size for overfiring.

• Check for a clean air filter.

• Check duct sizes to assure

adequate size for desired air flow.

The blower speed can be increased to

deliver more air over the heat

exchanger if the duct system is large

enough to allow the increase. If the

duct system is not of adequate size in-

creasing fan speed may result in less

air flow than originally found.

TEMPERATURE RISE TOO

LOW

• Check for proper fan speed.

• Check nozzle size to make sure it

is of proper size.

• Check for excessive soot in the

heat exchanger. Low system

efficiency may indicate a sooted

heat exchanger.

The motor speed can be changed to a

lower speed to decrease the air flow

over the heat exchanger.

TRUE-SPOT

True-Spot smoke tester (see figure 19)

by Bacharach is used to check smoke

levels in flue products.

Figure 19

Determining Temperature Rise

Loading...

Loading...