9

5. WATER CONNECTIONS

CAUTION: The heater inlet and outlet are NOT

interchangeable. They must be connected as instructed

below.

A

WARNING: Improper installation of any type of

automatic chemical feeders can result in serious damage

to, or premature failure of, the heater and such damage

will not be covered under warranty. Install a check valve

and/or a Hartford loop AFTER the heater and BEFORE

any chlorinating devices. Install any automatic chemical

feeders AFTER the heater.

1. Connect the heater in the return water line between

the filter and the pool/spa. See plumbing diagrams

on page 38 (without bypass) and page 39 (with

bypass).

2. Connect the filter outlet to the fitting marked INLET at

the bottom front of the unit.

3. Connect the fitting marked OUTLET to the return

piping to the pool/spa. Unit inlet/outlet connection

fittings are 2-inch PVC unions on models 4550-8550.

Water connections from the unit to the main return line can

be PVC pipe or exible pipe approved for the purpose and,

in either case, should be at least equal in size to the main

pool/spa circulation piping.

• Water flow to the unit will exceed 40 GPM (151 LPM)

for 4550 models or 50 GPM (189 LPM) for 5550-

8550 models. See Figure 64 for bypass instructions.

• To protect (completely bypass) the unit from any

harmful chemical treatments (i.e. Acid wash, back-

to-back super chlorinators, stain treatments, etc.); or

to be able to isolate the unit for service/repair or

freeze preparation and still allow pool/spa circulation

to continue.

In Heat/Cool models, a bypass assembly is included.

Please refer to the plumbing on page 39, for further

instruction.

Please note that some municipalities do not allow the use

of a shutoff valve on the efuent/outlet side of any heating

equipment, especially when there is one on the inlet side.

These entities typically instead allow a PVC tee and spring

check valve on the efuent/outlet side. This is allowed

by Raypak and can also double as your protection from

chemical feeders and chlorinators that are downstream of

the unit.

4. Operate the pump and check the system for leaks.

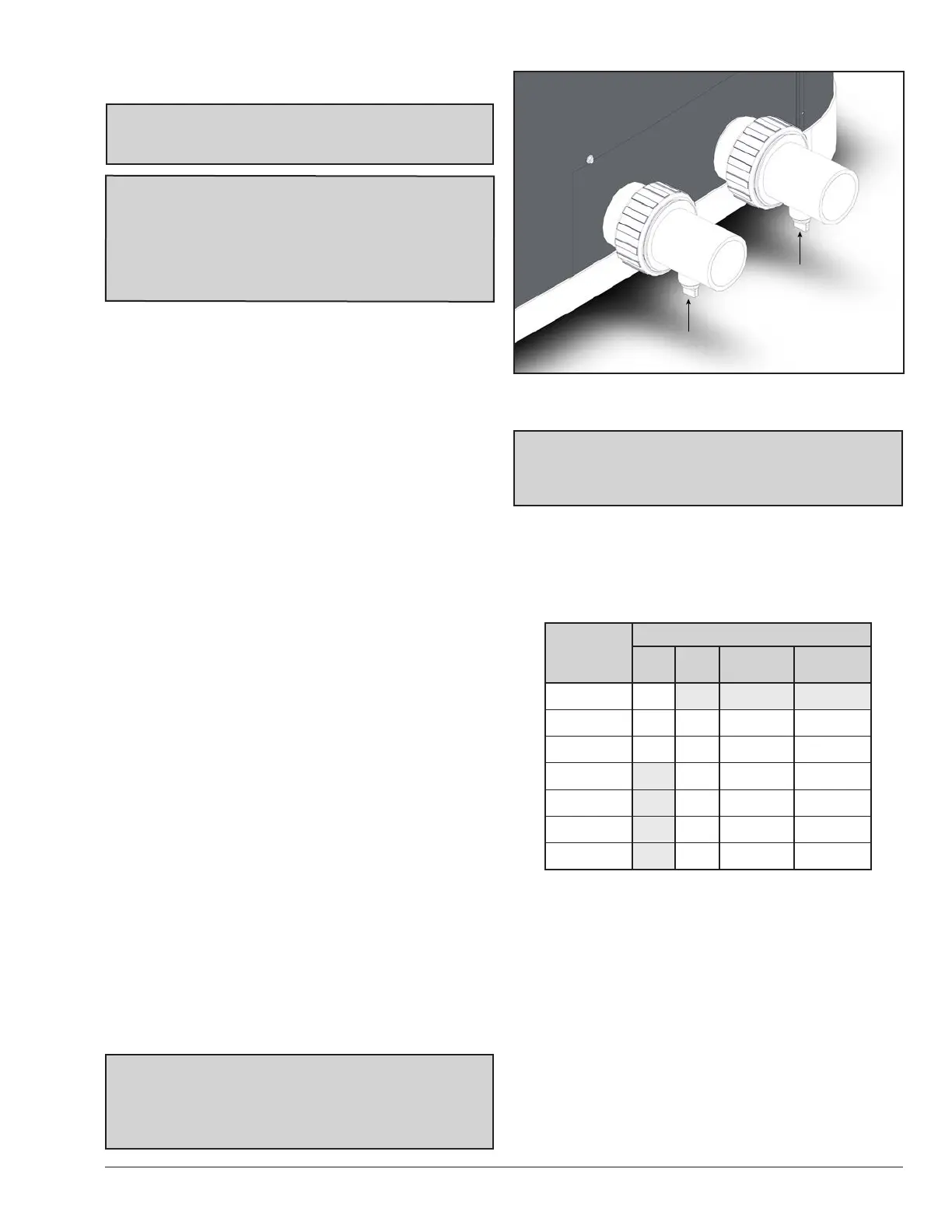

5. Drain plugs are located on each union fitting as shown

in Figure 6 for draining the system during winterizing.

NOTE: While it is possible to mount the upper union

with the drain plug vertically, the manufacturer has

determined that installing both unions with the drain

plugs facing down, as shown in Figure 6, provides for

the best draining of the system.

Figure 6. Water Connections/Drain Plugs

CAUTION: When the drain plugs are removed for

draining the system, ensure that they are stored in a

safe place for re-installation when needed to restart the

system.

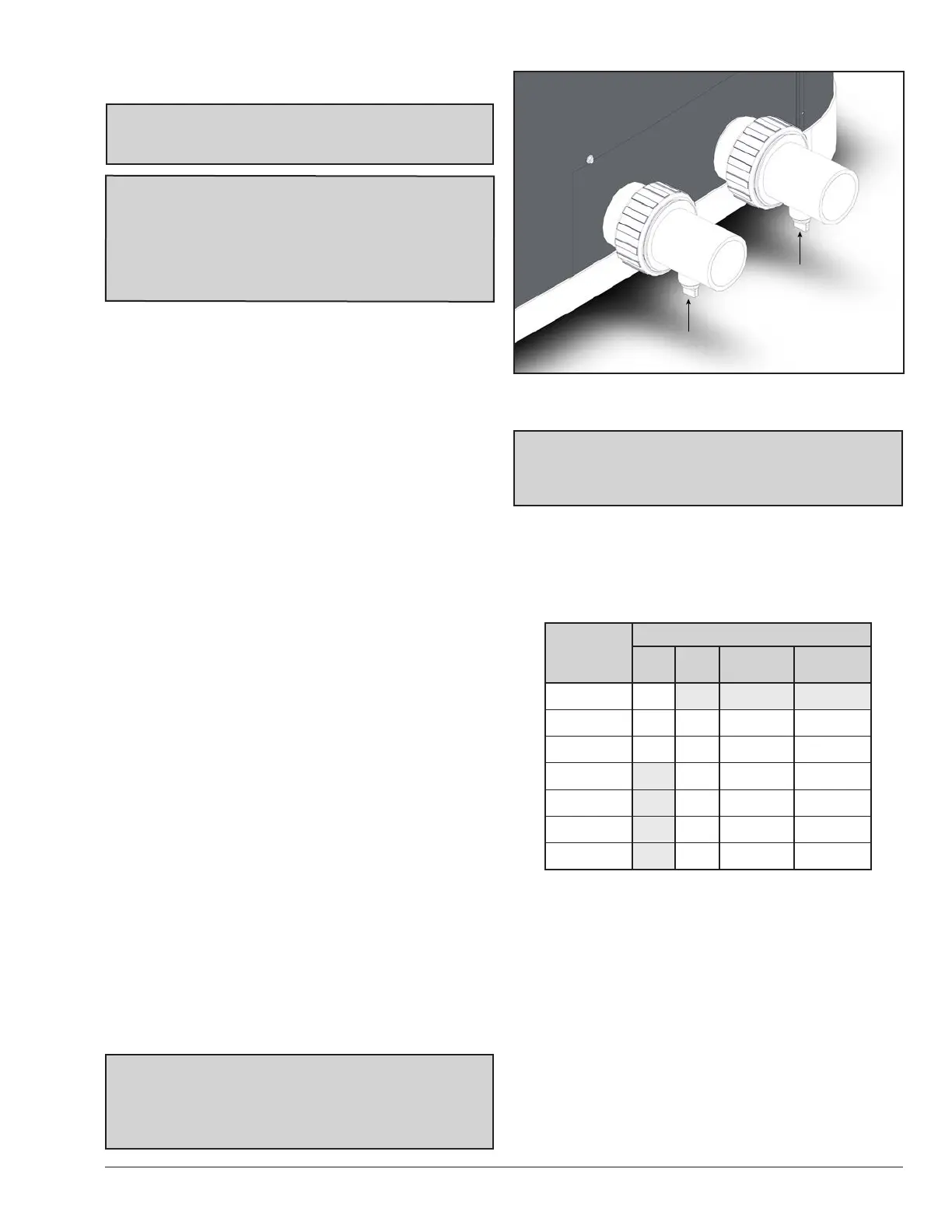

6. FLOW RATE & PRESSURE

DROP

For system pressure drop information, see Table B.

Flow

GPM (LPM)

Pressure Drop (PSI)

4550 5550

6550/

6550EHC

8550/

8550EHC

20 (750) 3.4

30 (113) 7 4 6 9

40 (151) 13 7 9 9

50 (189) 10 10 10

60 (227) 11 11 11

70 (265) 12 12 12

80 (303) 13 13 13

Note: Minimum recommended ow is 20 GPM. Multiply the pressure drop

in psi by 2.3067 to yield the pressure drop in Ft. H

2

O Head.

(Total Dynamic Head TDH)

Table B. Flow Rate & Pressure Drop Across the Heater

INLET

OUTLET

DRAIN PLUG

DRAIN PLUG

Loading...

Loading...