Loading...

Loading...

Do you have a question about the Roland PNC-900 Camm-1 and is the answer not in the manual?

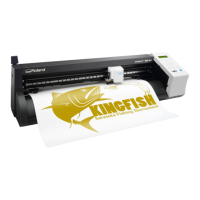

| Model | PNC-900 CAMM-1 |

|---|---|

| Interface | RS-232C |

| Power Supply | AC 100 to 240 V ±10%, 50/60 Hz |

| Type | Cutter |

| Max Media Thickness | 0.8 mm |

| Acceptable Material Width | 50 to 700 mm (2 to 27.5 inches) |

| Software Resolution | 0.025 mm/step (0.00098 inches/step) |

| Blade Force | 30 - 350 gf |

| Command System | Roland CAMM-GL |

| Power Consumption | Approx. 50 W |

| Power Requirements | 100 - 240 V, 50/60 Hz |

| Mechanical Resolution | 0.025 mm/step (0.00098 inches/step) |

Important safety advice for operating the PNC-900.

Instructions for establishing a connection between the PNC-900 and a computer.

Configuration of DIP switches for communication parameters and blade offset.

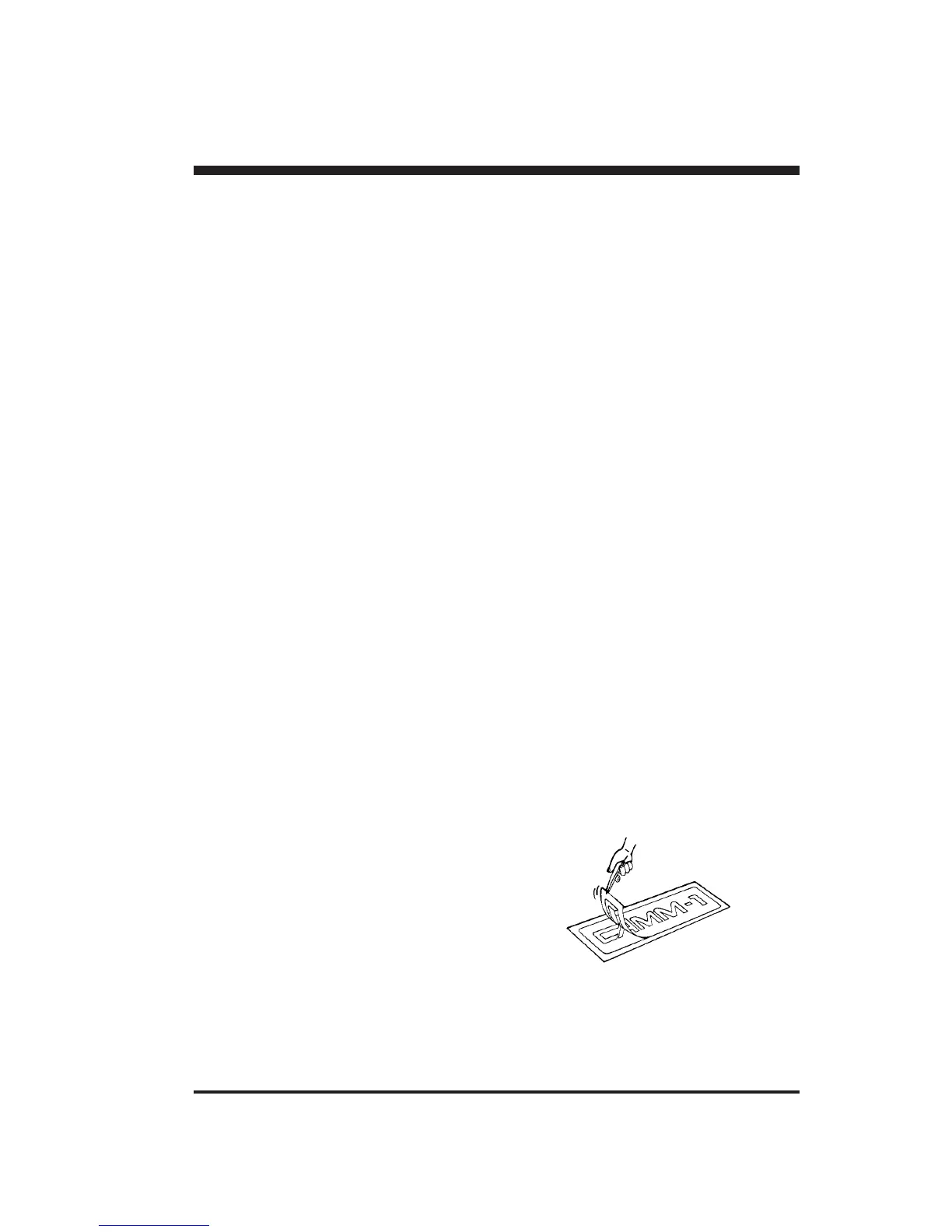

Step-by-step guide for installing and removing the cutting blade.

Procedure to test and confirm blade force settings for optimal cutting.

Guide on how to adjust the blade force using the control slider.

How to pause, resume, or terminate a cutting operation using the PAUSE key.

Troubleshooting steps for when the unit does not operate or the error LED blinks.