16 english

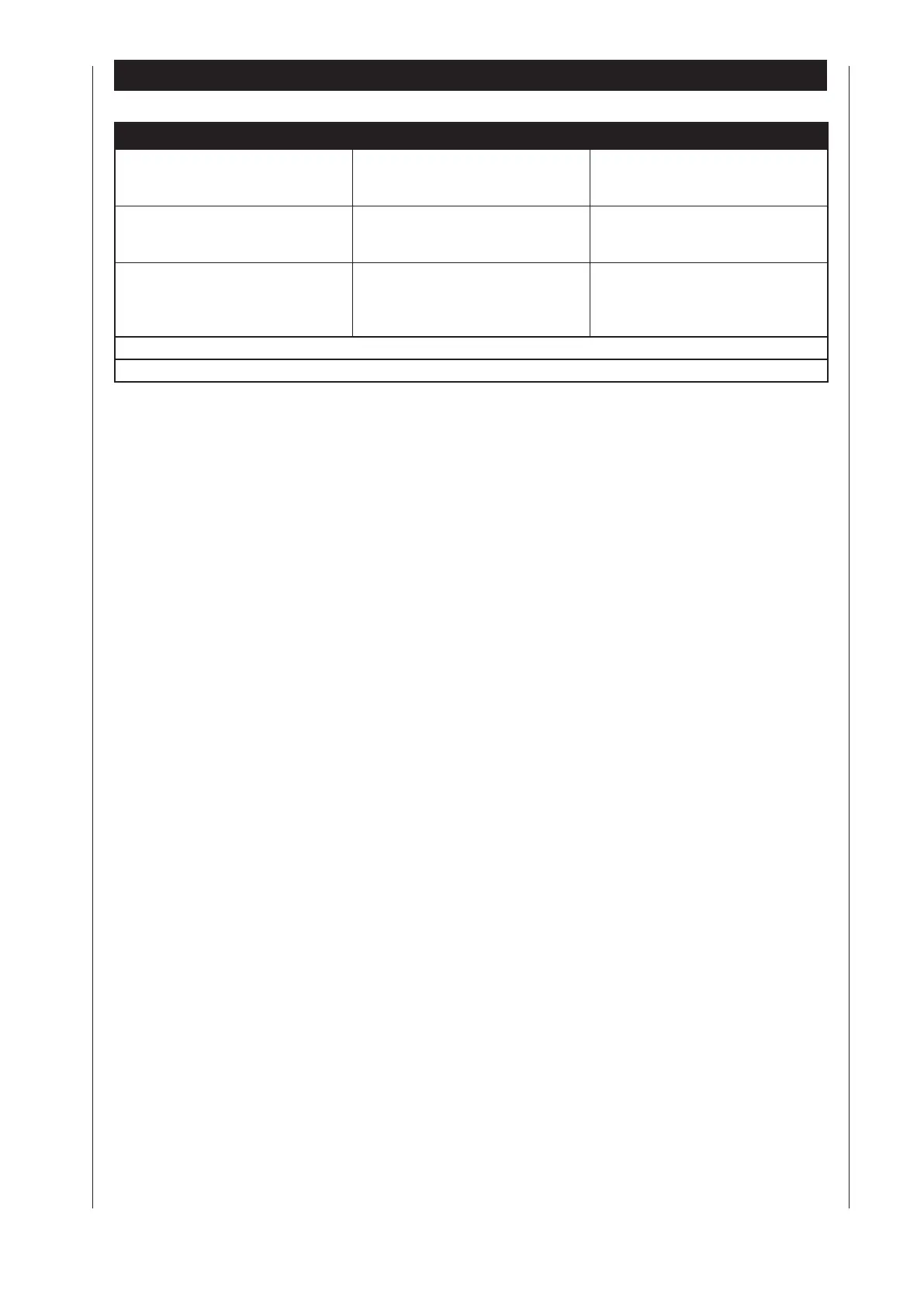

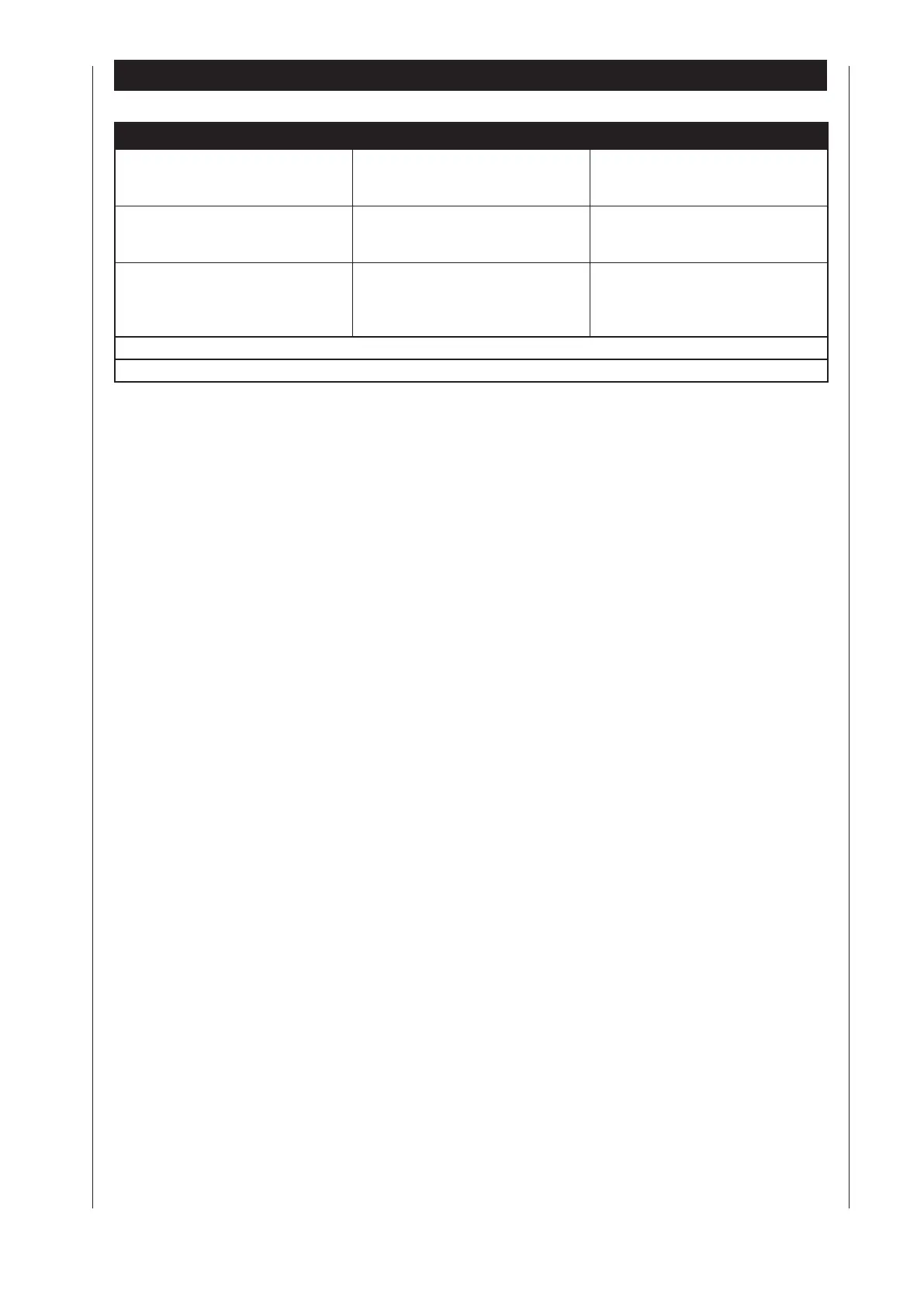

Trouble shooting

To repair faults, switch off the machine. Pull power plug.

Problem Possible Cause Relief

Irregular and discontinuous transport

at the thickness planing

Thickness desk not free of resin or not

free of oil.

Clean and spray (sliding spray) the

thickness desk regularly. This is valid

especially for wet and resinous woods.

Workpiece shoulder at the planing This is due to badly adjusted planer

knives.

The adjustment of the planer knives

has to be carried out with a lot of care

with help of the adjustment gauge.

Workpiece inaccuracy at the planing

(concave, convex)

At not exactly parallel standing

trimming desks due to improper

transport or similar.

Adjust the stiff trimming desk 1 mm

above the planing shaft body, as well

as parallel to the bottom plate.

Electrotechnical maintenance only by electric specialists!

At waste disposal of the machine all the local legal regulations have to be kept.

Loading...

Loading...