www.scheppach.com / service@scheppach.com / +(49)-08223-4002-99 / +(49)-08223-4002-58

34

|

GB

This can occur, for example, by handing it in at an

authorised collecting point for the recycling of waste

electrical and electronic equipment. Improper han

dling of waste equipment may have negative conse

quences for the environment and human health due

to potentially hazardous substances that are often

contained in electrical and electronic equipment. By

properly disposing of this product, you are also con

can obtain information on collection points for waste

equipment from your municipal administration, public

waste disposal authority, an authorised body for the

disposal of waste electrical and electronic equipment

or your waste disposal company.

14. Disposal and recycling

The equipment is supplied in packaging to prevent it

from being damaged in transit. The raw materials in

this packaging can be reused or recycled. The equip

ment and its accessories are made of various types

of material, such as metal and plastic. Defective com

ponents must be disposed of as special waste. Ask

your dealer or your local council.

Old devices must not be disposed of with house-

hold waste!

This symbol indicates that this product must

not be disposed of together with domestic

waste in compliance with the Directive

(2012/19/EU) pertaining to waste electrical and

electronic equipment (WEEE). This product must be

disposed of at a designated collection point.

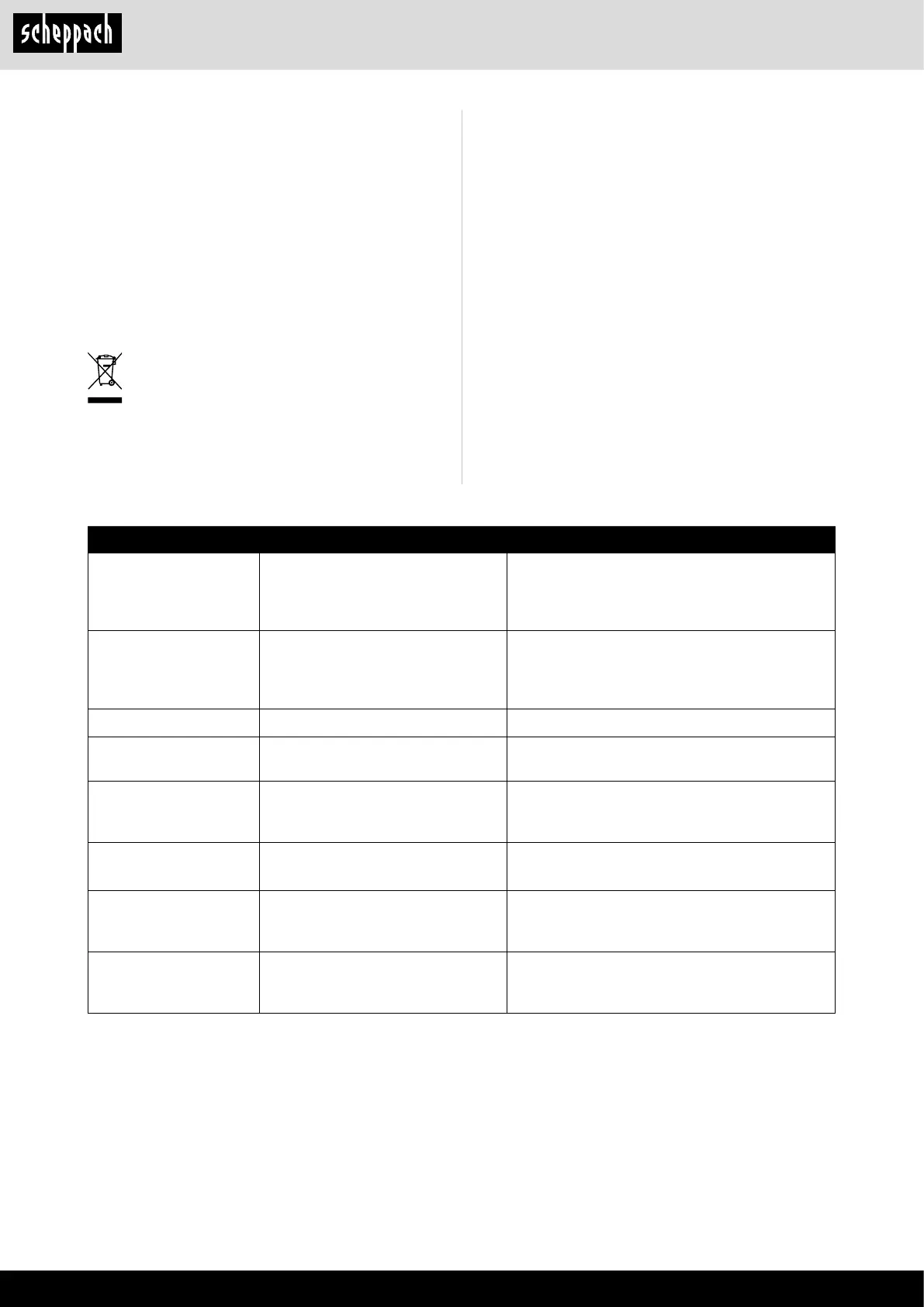

15. Troubleshooting

Problem Possible Cause Help

The motor does not run. Faulty motor, power supply cable or

plug. Burned out fuses.

Have the machine checked by skilled personnel.

Do not try to repair the machine yourselves as it

them if necessary.

The motor starts slowly

and does not reach run

ning speed.

Low power supply voltage. Damaged

windings. Burned out capacitor.

Ask for the Electricity Board to check the voltage

available. Have the machine motor checked by

skilled personnel. Have the capacitor replaced by

skilled personnel.

Excessive motor noise. Damaged windings. Faulty motor. Have the motor checked by skilled personnel.

The motor does not reach

full power.

Overloaded circuit due to lighting,

utilities or other motors.

Do not use other utilities or motors on the circuit to

which the track saw is connected.

Motor overheats easily Overload of the motor; inadequate

cooling of the motor

Prevent overloading the motor when cutting;

remove dust from the motor to ensure an optimum

cooling of the motor

Decrease in cutting

power when sawing

The saw blade is too small (sharp

ened too often)

The saw cut is rough or

wavy

The saw blade is dull; the tooth shape

is not suited to the thickness of the

material

saw blade

The work piece rips or

splinters

The cutting pressure is excessive or

the saw blade is not suited to the ap

plication

Use the correct saw blade

Loading...

Loading...