Loading...

Loading...

Do you have a question about the Sinee A90-4T060 and is the answer not in the manual?

| Rated Power | 60 kW |

|---|---|

| Output Power | 60 kW |

| Frequency | 50/60Hz |

| Input Voltage | 380V - 480V |

| Output Voltage | 380V - 480V |

| Efficiency | 98% |

| Protection Features | Over voltage, Under voltage, Over current, Short circuit |

General safety guidelines before installation, during operation, and maintenance.

Specific safety warnings and dangers related to inverter installation.

Safety warnings concerning installation location and components.

Warnings about handling components, installation location, and heat dissipation.

Dangers and warnings associated with wiring the inverter and its components.

Safety checks required before powering on the inverter, including voltage and connections.

Safety precautions to follow after the inverter is powered on, emphasizing avoiding contact with live parts.

Safety warnings to prevent injury or damage during inverter operation.

Critical safety measures for performing maintenance, including power-off procedures.

Critical conditions and management aspects for the inverter's installation site.

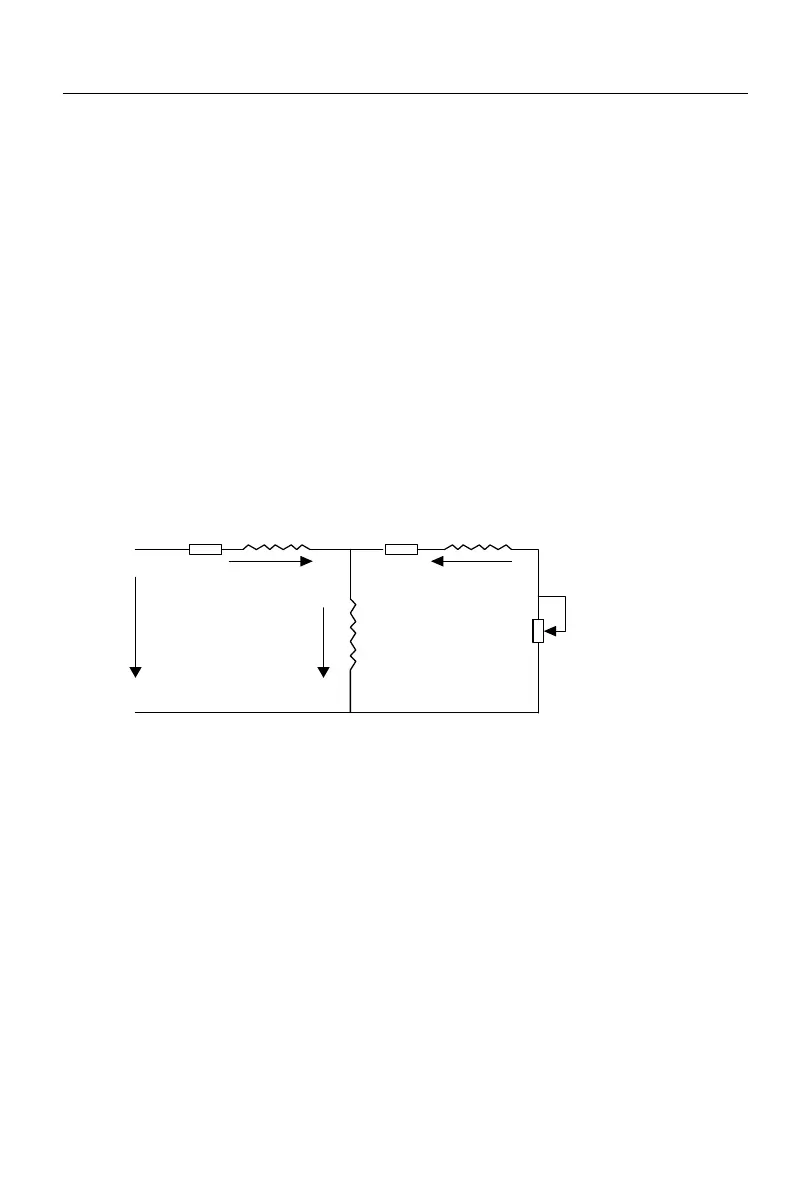

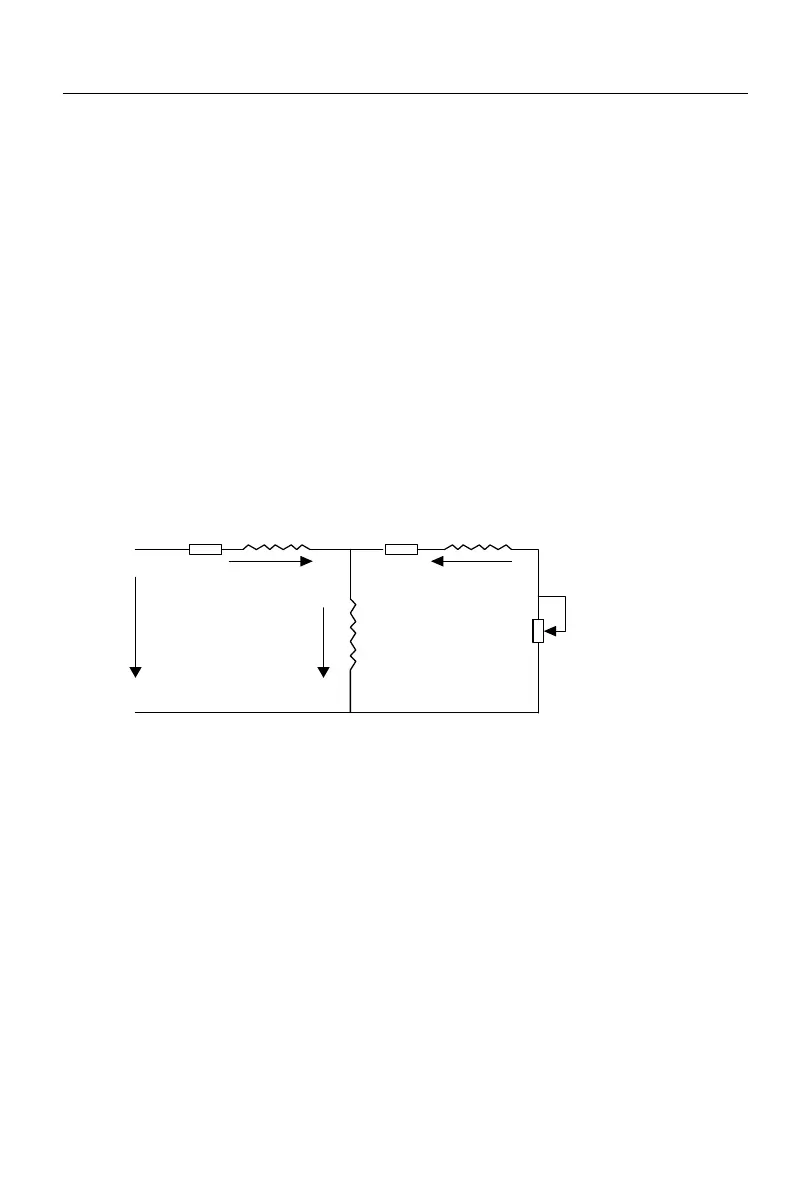

Composition and schematic layout of the inverter's main circuit terminals.

Essential requirements and methods for proper grounding of the inverter.

Introduction to the control circuit terminals and their functionalities.

A comprehensive checklist for verifying all connections and settings before powering on.

Explains the process of identifying motor parameters to optimize inverter control.

Importance and process of motor parameter self-identification for vector control.

Precautions to take before performing motor parameter self-identification.

Step-by-step procedure for performing motor parameter self-identification.

Table detailing fault codes, types, causes, and solutions for common inverter issues.

Analysis of common failures related to parameter settings and motor rotation issues.

Procedures for daily inspection and regular maintenance of the inverter.