Sharpening and Maintenance of

Oilomatic Picco Chain

Foreword

Like any other cutting tool, the saw chain is sUbject

to

normal wear. A properly sharpened chain will eat into the

wood and require very little effort on the part of the

operator.

For this reason you should never attempt to cut

with a dull or damaged chain.

A carefully sharpened saw chain offers many benefits,

i.

e.

a higher cutting capacity, clean and smooth cuts - this

means less operator effort, a lower fuel consumption and

minimum wear.

There are a few crucial angles which must be maintained

in

order to obtain good results when sharpening a chain.

They are explained below.

Filing angle

The filing angle on the Oilomatic-Picco chain

is

35°; the

chain is initially sharpened to this angle before leaving

the factory. However, if you use the chain primarily for

cutting hardwood or frozen timber, it is best to sharpen

it

at

an angle of30°.

Always make sure that the filing angle is exactly the same

on

all cutters. Irregular angles will cause the chain to run

roughly and unevenly

as

well

as

increase the rate

ot

wear

and result

in

chain breakage.

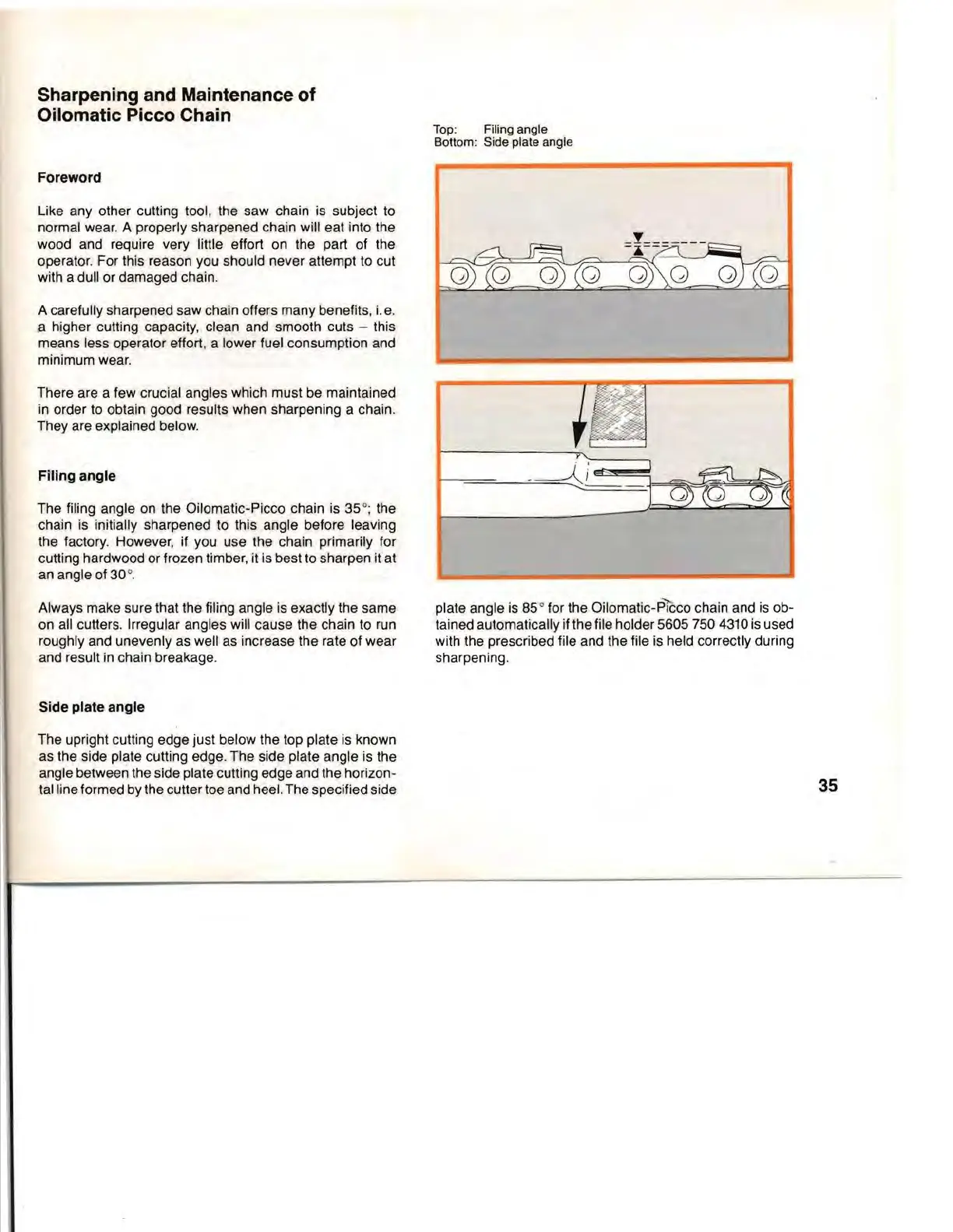

Side plate angle

The upright cutting edge just below the top plate

is

known

as

the side plate cutting edge. The side plate angle

is

the

angle between the side plate cutting edge and the horizon-

tal line formed by the cutter toe and heel. The specified side

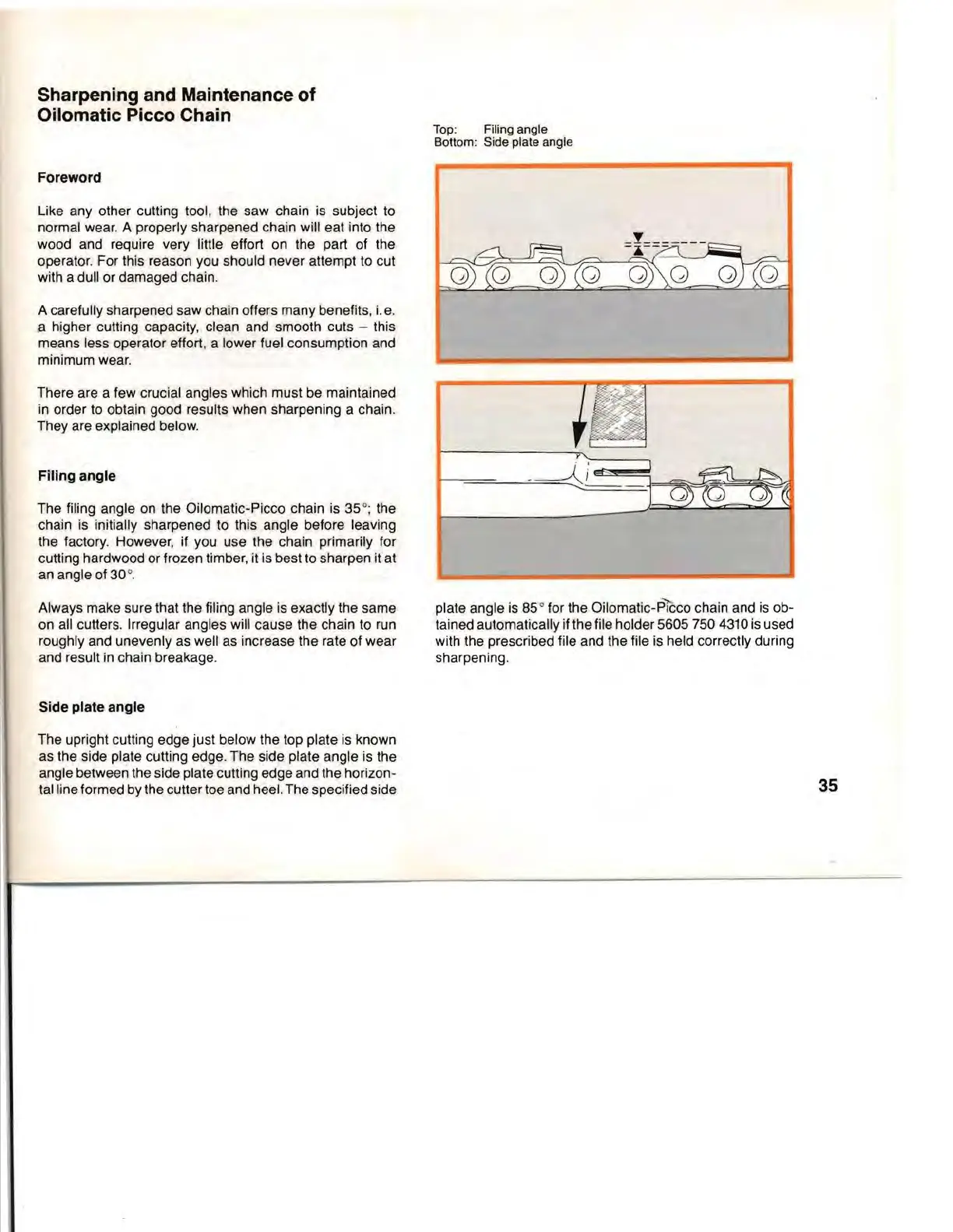

Top: Filing angle

Bottom: Side plate angle

plate angle

is

85

° for the Oilomatic-Plcco chain and

is

ob-

tained automatically if the file holder

56057504310

is used

with the prescribed file and the file

is

held correctly during

sharpening.

35

Loading...

Loading...