14 Series 4180 Powerhead

If the action of the starter rope

becomes very stiff and the rope

rewinds very slowly or not

completely, it can be assumed that

the starter mechanism is in order

but plugged with dirt. At very low

outside temperatures the lubricating

oil on the rewind spring may thicken

and cause the spring windings to

stick together. This has a

detrimental effect on the function of

the starter mechanism. In such a

case it is sufficient to clean the

rewind spring with a standard

commercial cleaner and then coat it

with STIHL special lubricant.

Carefully pull out the starter rope

several times and allow it to rewind

until its normal smooth action is

restored.

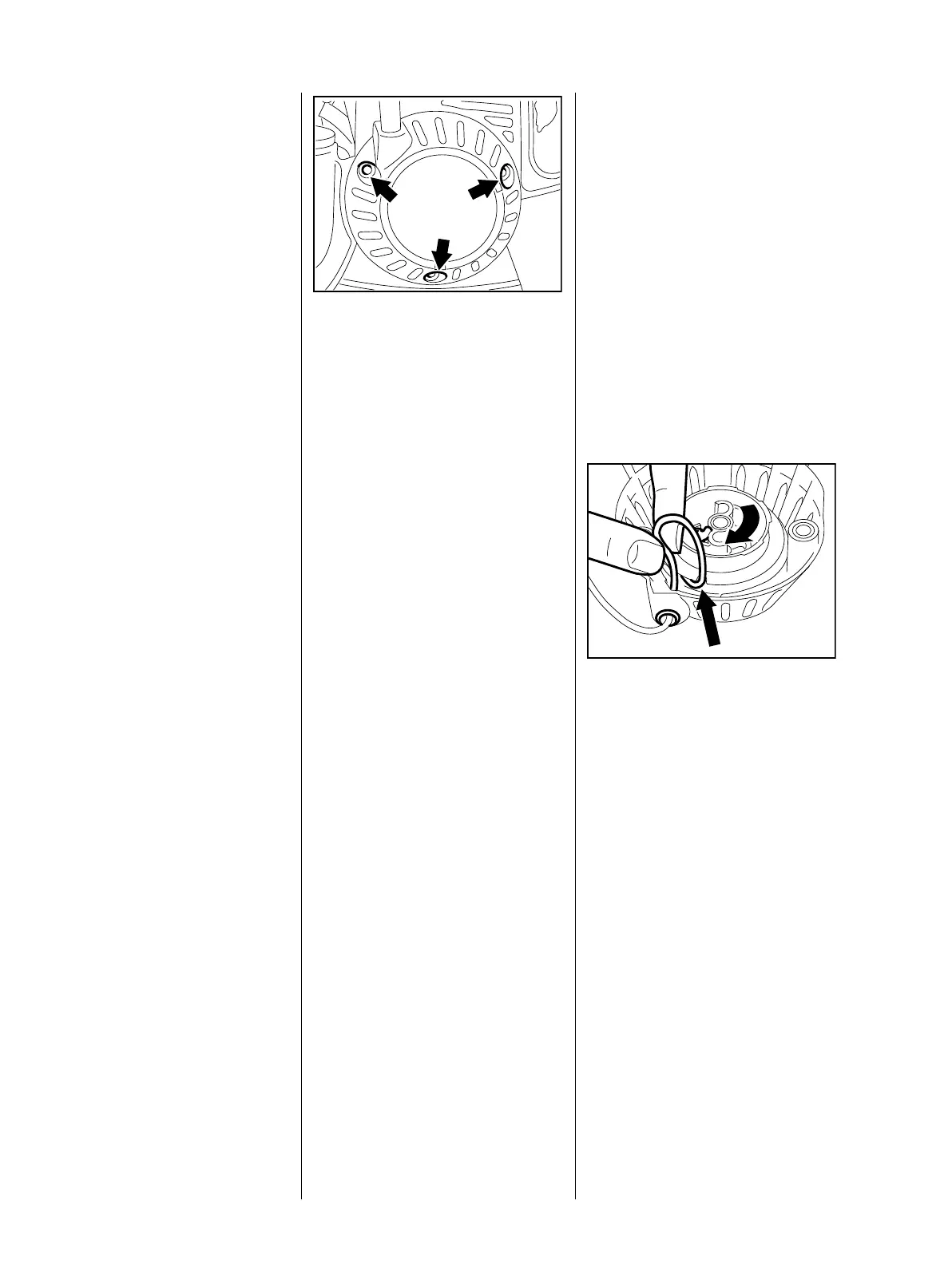

: Remove the screws (arrows)

from the rewind starter.

– Lift away the rewind starter.

Reassemble in the reverse

sequence.

– Tighten down the screws, b 3.4

– Remove the rewind starter,

b 5.2

Relieving tension of rewind

spring:

The spring will not be under tension

if the starter rope is broken.

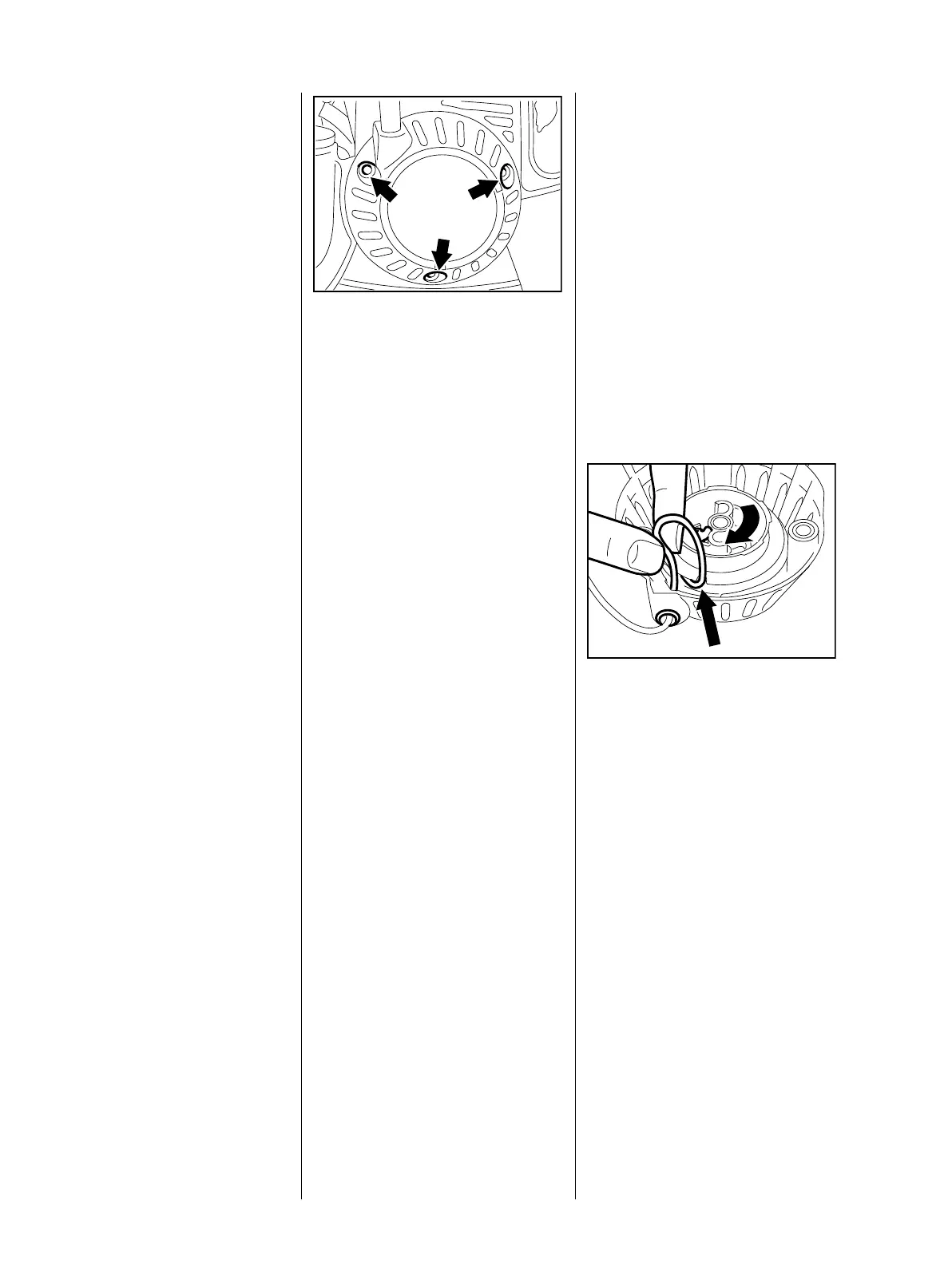

– Pull out the starter rope about

20 cm and hold the rope rotor

steady.

– Engage the rope in the notch on

the rotor, and make a loop.

– Use the starter rope to turn the

rotor clockwise until tension is

relieved.

5. Rewind Starter/Shroud

5.1 General

5.2 Removing and Installing 5.3 Rope Rotor

Loading...

Loading...