50 Series 4180 Powerhead

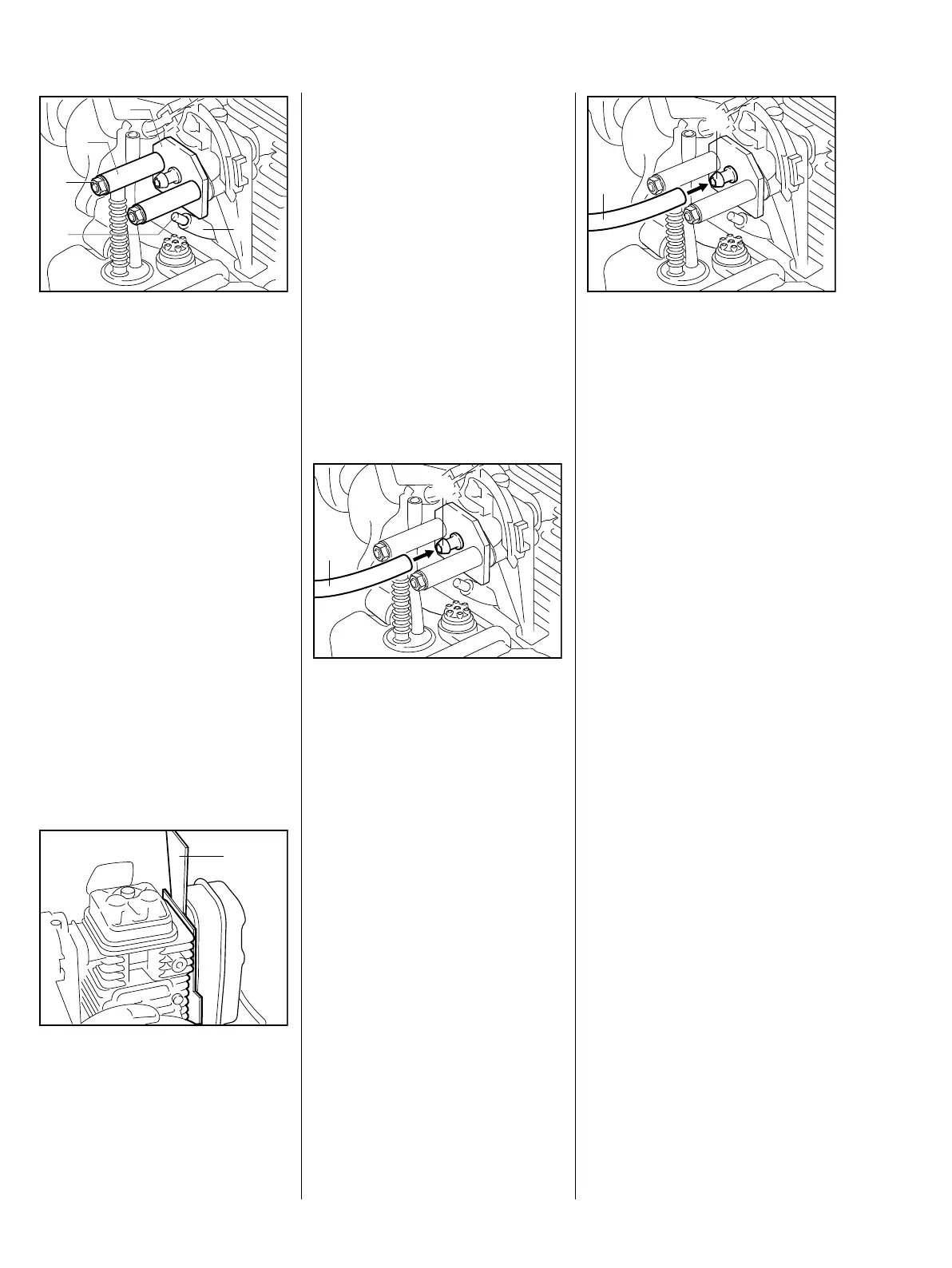

: Push the test flange (1)

1119 850 4201 into position.

: Fit the sleeves (2)

0000 963 1008 and secure them

with the nuts (3).

: Seal the impulse hose (4) with a

suitable plug (5).

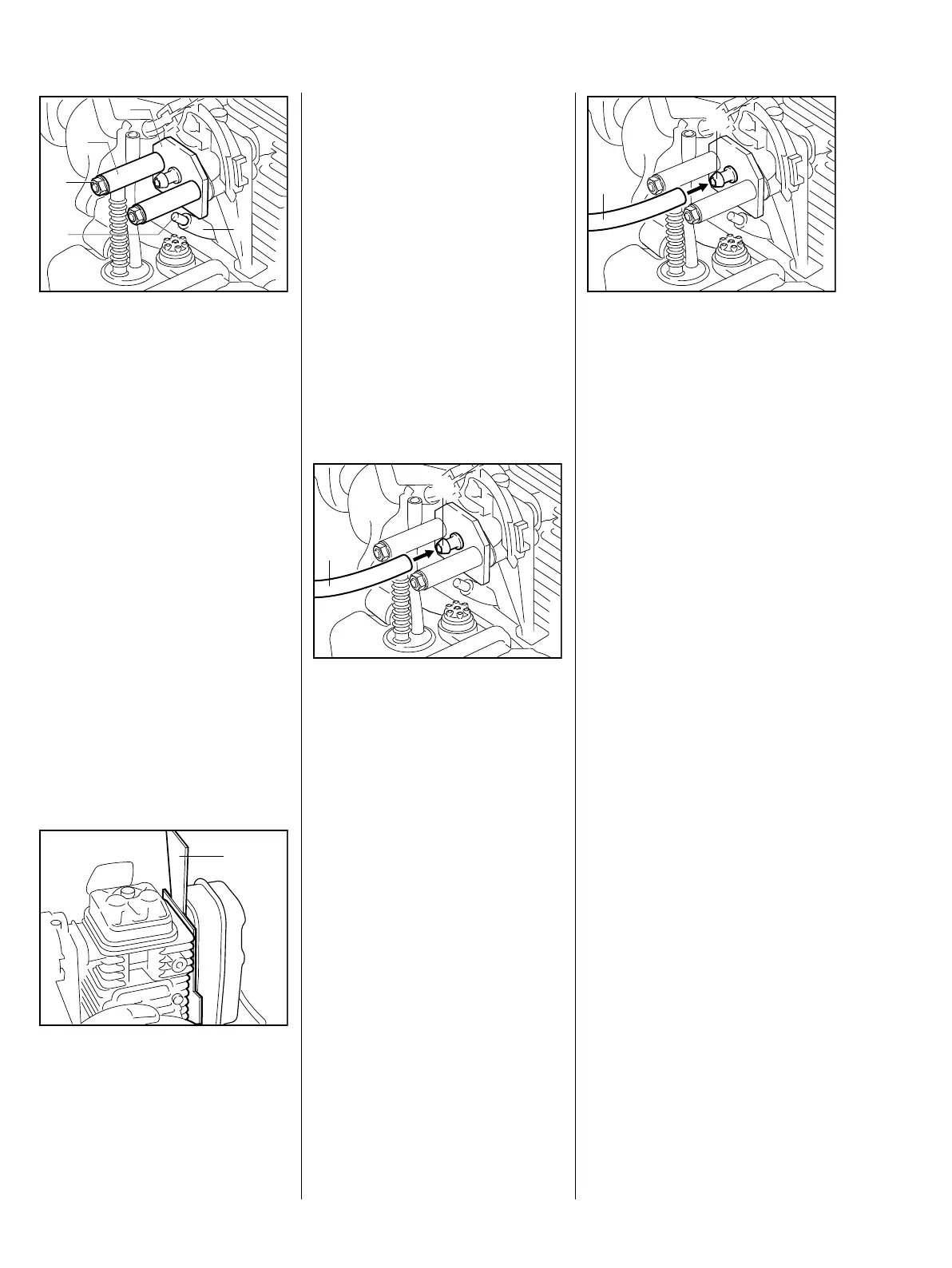

– Loosen the muffler mounting

screws.

: Fit the sealing plate (1)

0000 855 8106 between the

muffler and cylinder exhaust port

– the sealing plate must

completely cover the opening in

the muffler.

– Tighten down the screws firmly.

Vacuum test

Oil seals tend to fail when subjected

to a vacuum, i.e. the sealing lip lifts

away from the crankshaft during the

piston's induction stroke because

there is no internal counterpressure.

: Connect suction hose (1) of

vacuum pump 0000 850 3501 to

the nipple (2).

– Close the vent screw on the

pump.

– Operate the vacuum pump until

the pressure gauge indicates a

vacuum of 0.5 bar.

If the vacuum reading remains

constant, or drops to no more than

0.3 bar within 20 seconds, it can be

assumed that the oil seals are in

good condition.

If the vacuum drops to less than 0.3

bar within 20 seconds, the oil seals

are defective and have to be

replaced, b 7.8.1.

Pressure test

: Connect pressure hose (1) of

tester 1106 850 2905 to the

nipple (2).

– Close the vent screw on the

rubber bulb.

– Operate the pump bulb until the

pressure gauge indicates a

pressure of 0.5 bar.

If this pressure remains constant for

at least 20 seconds, the engine

housing is airtight.

If the pressure drops, the leak must

be located and the faulty part

replaced.

– To find the leak, coat the suspect

area with oil and pressurize the

crankcase. Bubbles will appear if

a leak exists.

Loading...

Loading...