15BT 360

English

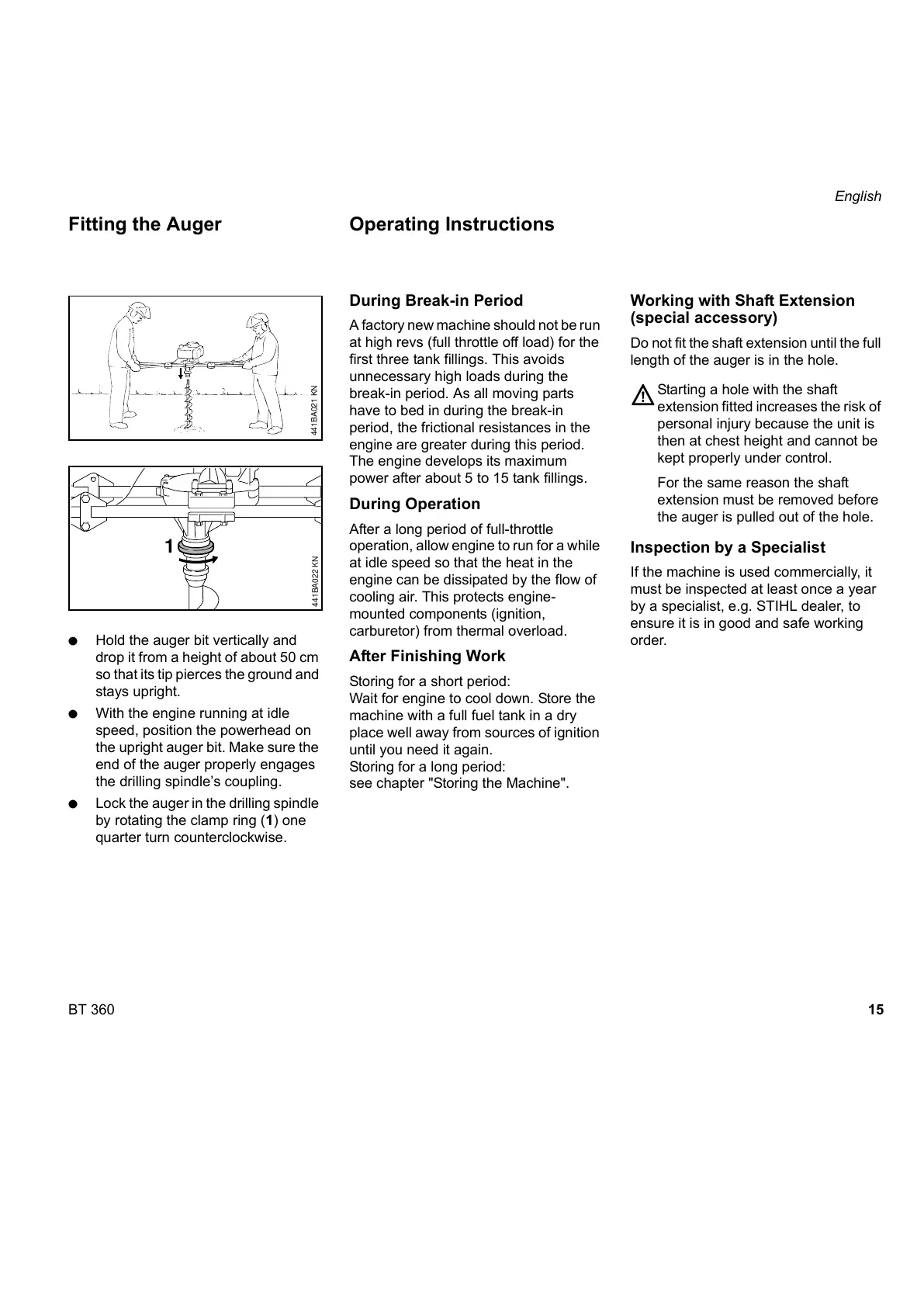

: Hold the auger bit vertically and

drop it from a height of about 50 cm

so that its tip pierces the ground and

stays upright.

: With the engine running at idle

speed, position the powerhead on

the upright auger bit. Make sure the

end of the auger properly engages

the drilling spindle’s coupling.

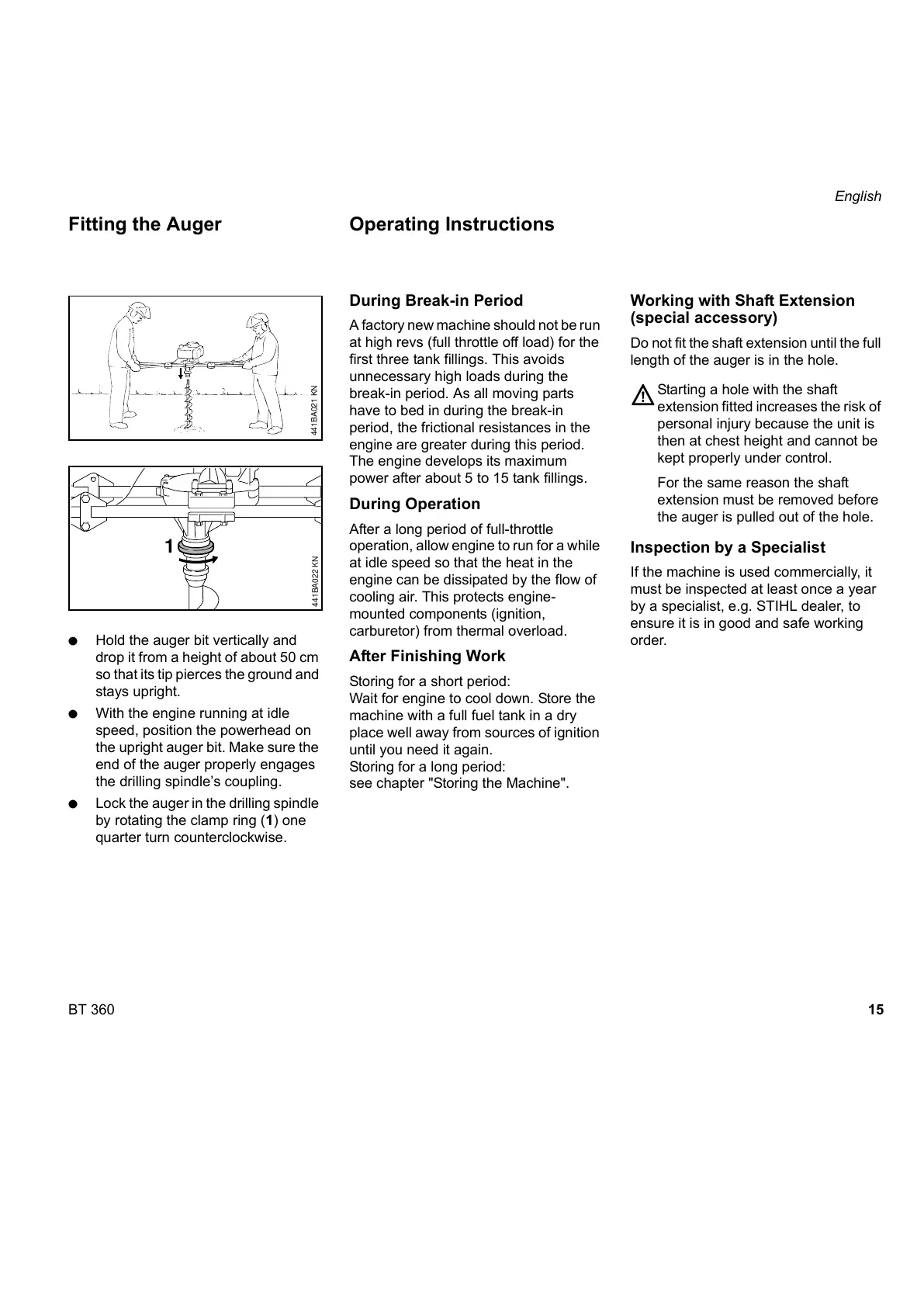

: Lock the auger in the drilling spindle

by rotating the clamp ring (1) one

quarter turn counterclockwise.

During Break-in Period

A factory new machine should not be run

at high revs (full throttle off load) for the

first three tank fillings. This avoids

unnecessary high loads during the

break-in period. As all moving parts

have to bed in during the break-in

period, the frictional resistances in the

engine are greater during this period.

The engine develops its maximum

power after about 5 to 15 tank fillings.

During Operation

After a long period of full-throttle

operation, allow engine to run for a while

at idle speed so that the heat in the

engine can be dissipated by the flow of

cooling air. This protects engine-

mounted components (ignition,

carburetor) from thermal overload.

After Finishing Work

Storing for a short period:

Wait for engine to cool down. Store the

machine with a full fuel tank in a dry

place well away from sources of ignition

until you need it again.

Storing for a long period:

see chapter "Storing the Machine".

Working with Shaft Extension

(special accessory)

Do not fit the shaft extension until the full

length of the auger is in the hole.

Starting a hole with the shaft

extension fitted increases the risk of

personal injury because the unit is

then at chest height and cannot be

kept properly under control.

For the same reason the shaft

extension must be removed before

the auger is pulled out of the hole.

Inspection by a Specialist

If the machine is used commercially, it

must be inspected at least once a year

by a specialist, e.g. STIHL dealer, to

ensure it is in good and safe working

order.

Fitting the Auger

441BA021 KN

441BA022 KN

1

Operating Instructions

Loading...

Loading...