- Slip the rubber boot off the

ignition lead.

- Cut new ignition lead to length

(see parts list or cut to same

length as old lead).

•

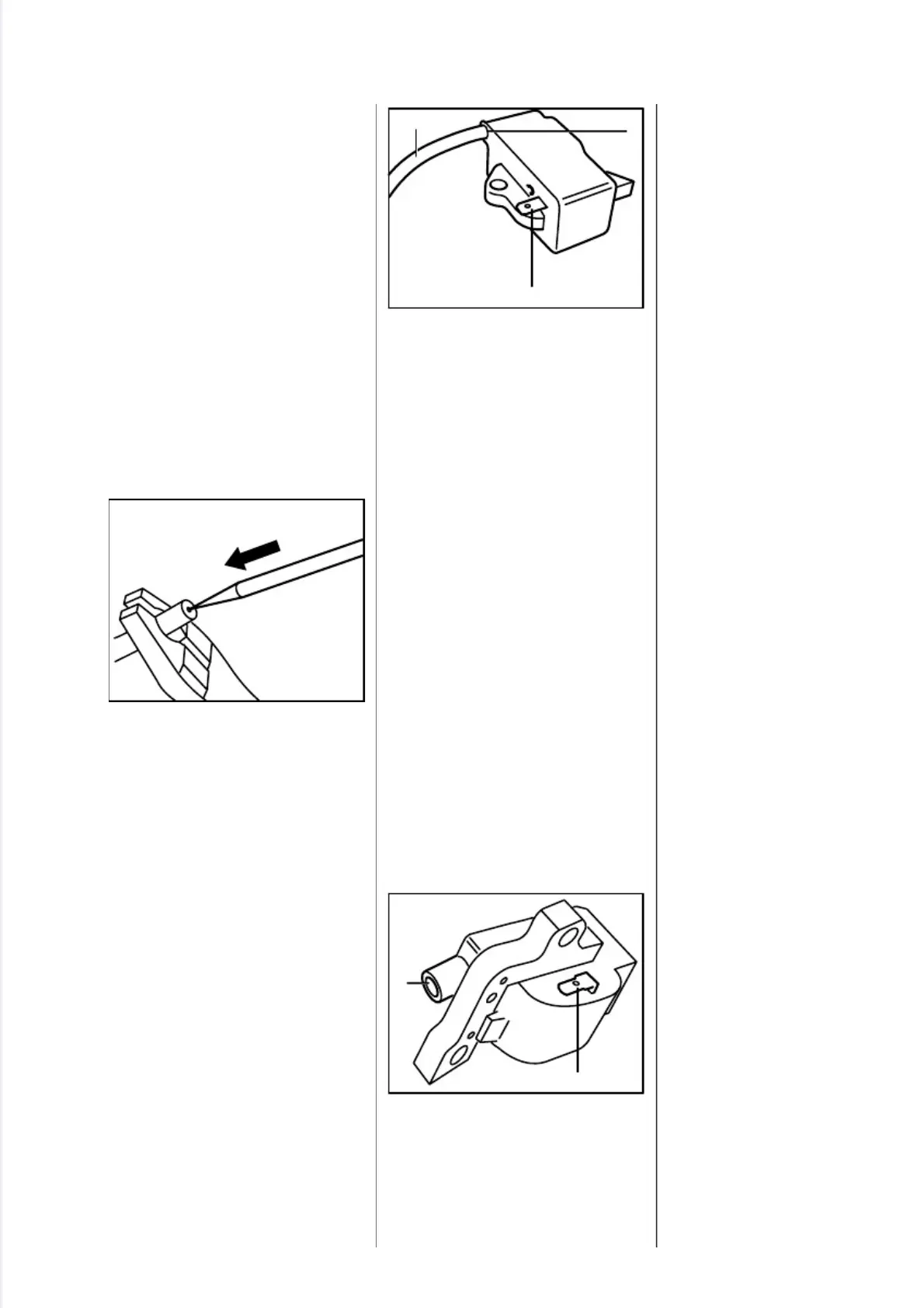

Use a pointed tool (awl or gimlet)

to pierce the center of the

ignition lead that is to be scre-

wed into the module.

- Slip the rubber boot over the

lead.

- Pack the high voltage output with

STIHL multipurpose grease - see

13.2.

Important:Do not use graphite

grease (Molykote) or silicone

insulating paste for this job.

- Screw home the ignition lead.

- Fit rubber boot on the high

voltage output.

- Fit cable retainer and spark plug

boot.

- Fit the ignition module - see

5.3.3.

The ignition module accommo-

dates all the components required

to control ignition timing.

FS 120...350, FR 350

There are two electrical connec-

tions on the coil body:

1. the high voltage output (1) with

ignition lead (2)

2. the connector tag (3) for the

short circuit wire

A vibration damping pad is bonded

to the side of the ignition module.

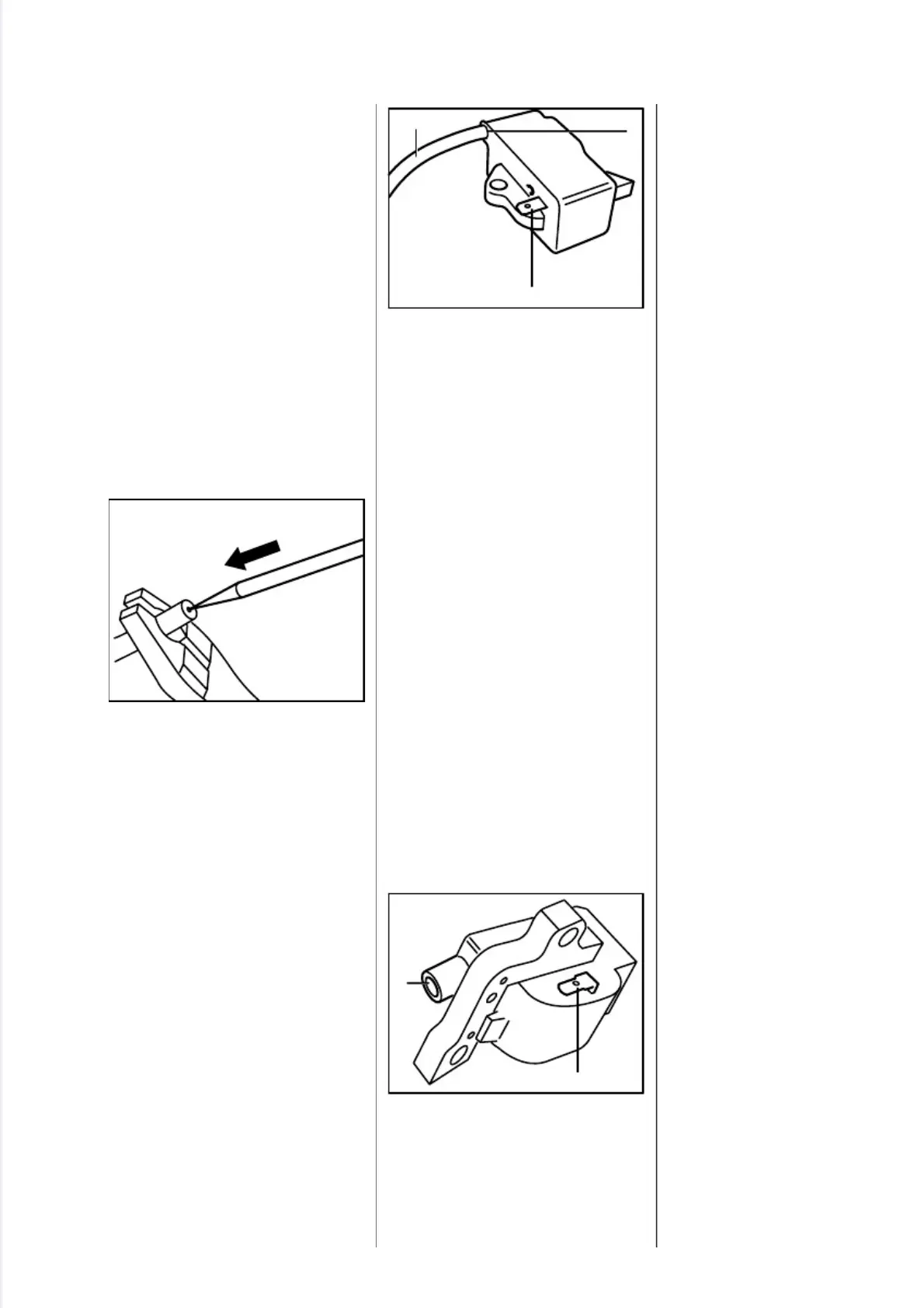

FS 400/450, FR 450

There are two electrical connec-

tions on the coil body:

1. the high voltage output (1)

2. the connector tag (2) for the

short circuit wire

Accurate testing of the ignition

module is only possible with

sophisticated test equipment. For

this reason it is only necessary to

carry out a spark test in the work-

shop. A new ignition module must

be installed if no ignition spark is

obtained (after checking that

wiring and stop switch are in good

condition).

5.3 Ignition Module

2

5

0

R

A

0

9

5

1

2

V

A

3

3

8

R

A

1

4

2

V

A

2

5

0

R

A

0

5

4

2

1

3

V

A

FS 120, 200, 300, 350, 400, 450, FR 350, 450 25

Loading...

Loading...