Do you have a question about the Stihl MS 201 C-M and is the answer not in the manual?

| Idle speed | 3000 RPM |

|---|---|

| Motor type | 2-stroke motor |

| Chain pitch | 3/8 \ |

| Blade length | 400 mm |

| Product color | Black, Grey, Orange |

| Motor speed (max) | 10500 RPM |

| Oil tank capacity | 0.22 L |

| Fuel tank capacity | 0.31 L |

| Engine displacement | 35.2 cm³ |

| Kickback protection | Yes |

| Engine power | 2.4 hp |

| Power source | Gasoline |

| Sound power level | 112 dB |

| Vibration emission | 3.3 m/s² |

| Sound pressure level | 99 dB |

| Weight | 3900 g |

|---|

Explains the meaning of pictograms attached or embossed on the machine.

Describes how operating and safety instructions are supported by illustrations and text.

Information on how STIHL continually improves products and handles changes.

Details on the operator's physical and mental condition required for safe use.

Recommendations for protective apparel to reduce the risk of injury.

Guidelines for safe refueling, including location and precautions against fire.

Explanation of kickback occurrence and its dangerous effects.

Details on the chain brake system designed to reduce kickback injury risks.

Precautions when cutting logs under tension to avoid pinching.

Method for felling large diameter trees requiring sectioning cuts.

Method for felling large trees using a dangerous plunge-cut technique.

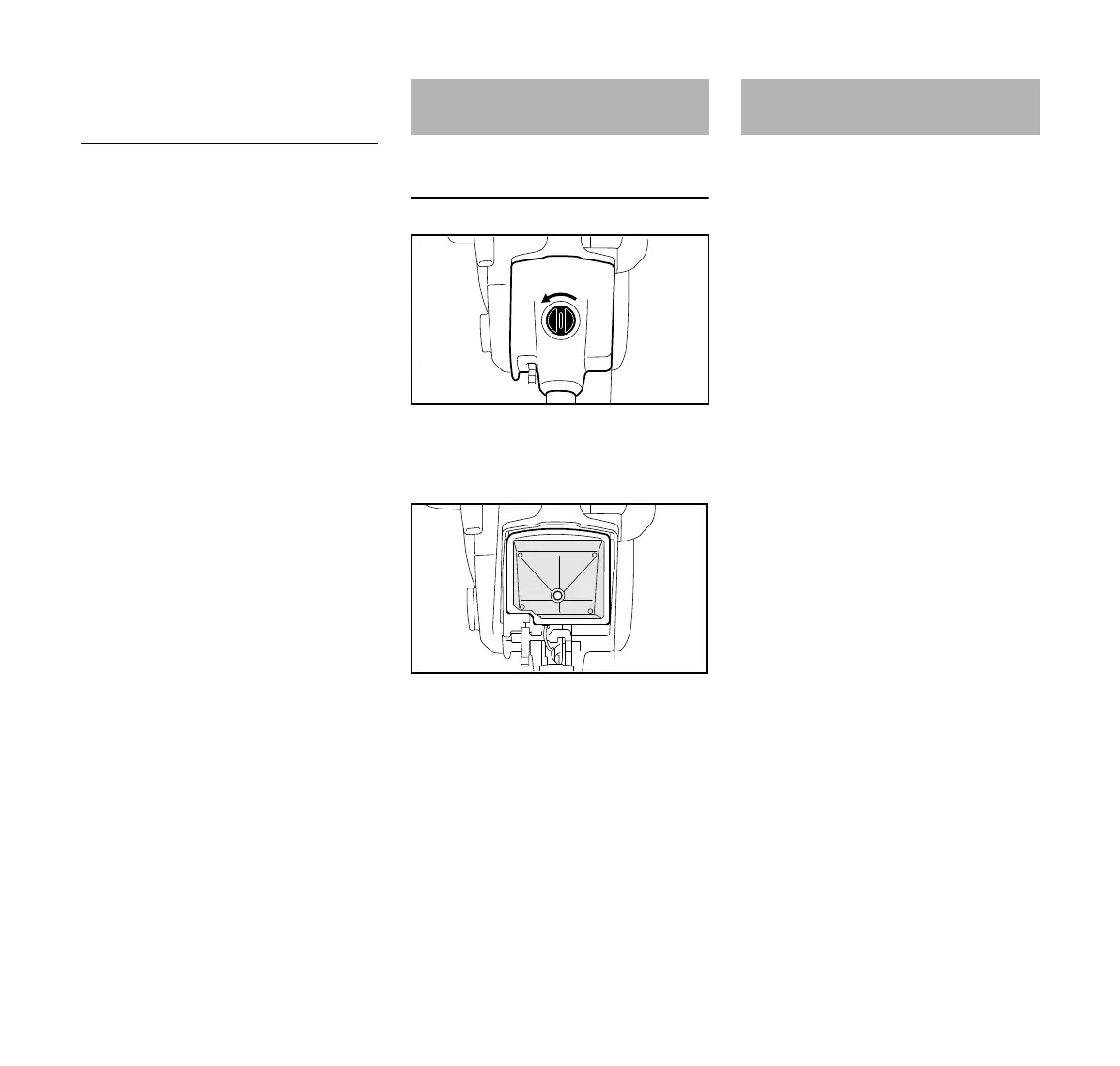

Procedure to disengage the chain brake for mounting the bar and chain.

Steps for fitting the saw chain onto the guide bar and sprocket.

How to lock the chain using the chain brake for safety.

Procedure for releasing the chain brake before operation.

Explanation of the Master Control Lever positions for starting and stopping.

Guidance for operating a new machine during its initial break-in period.

Instructions for operating the saw during normal work periods.

How to check chain tension when the chain is cold.

Steps to take after finishing work, including chain slackening.

Instructions for storing the machine for short periods.

Guidelines for storing the machine for extended periods.

Overview of M-Tronic electronic engine management system.

How M-Tronic adapts to extremely changed operating conditions.

Step-by-step guide to removing the spark plug.

Instructions for fitting a new chain sprocket.

Benefits and importance of using a properly sharpened saw chain.

Guidance on using a file holder for sharpening saw chains.

Methods for checking sharpening and side plate angles.

Explanation of depth gauge setting and its impact on cutting.

Procedure for lowering depth gauges after sharpening.

Details on recommended guide bars, saw chains, and sprockets.

Warranty statement specific to emissions control for non-California regions.

Owner's responsibilities regarding maintenance and warranty claims.

Warranty statement specific to emissions control for California.

Owner's responsibilities regarding maintenance and warranty claims in California.