47MS 231, MS 231 C, MS 251, MS 251 C

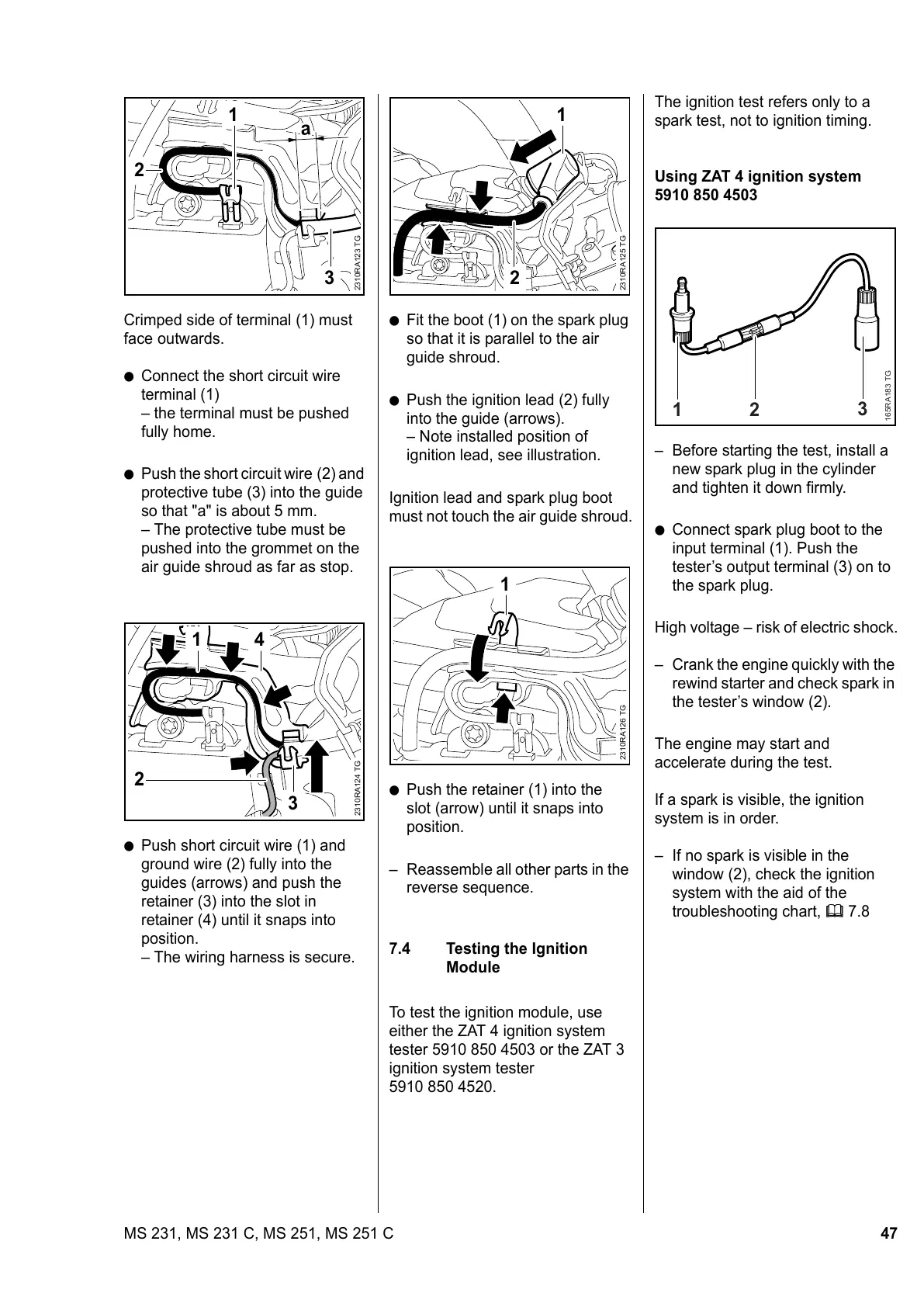

Crimped side of terminal (1) must

face outwards.

: Connect the short circuit wire

terminal (1)

– the terminal must be pushed

fully home.

: Push the short circuit wire (2) and

protective tube (3) into the guide

so that "a" is about 5 mm.

– The protective tube must be

pushed into the grommet on the

air guide shroud as far as stop.

: Push short circuit wire (1) and

ground wire (2) fully into the

guides (arrows) and push the

retainer (3) into the slot in

retainer (4) until it snaps into

position.

– The wiring harness is secure.

2310RA123 TG

1

2

3

a

2310RA124 TG

1

2

3

4

: Fit the boot (1) on the spark plug

so that it is parallel to the air

guide shroud.

: Push the ignition lead (2) fully

into the guide (arrows).

– Note installed position of

ignition lead, see illustration.

Ignition lead and spark plug boot

must not touch the air guide shroud.

: Push the retainer (1) into the

slot (arrow) until it snaps into

position.

– Reassemble all other parts in the

reverse sequence.

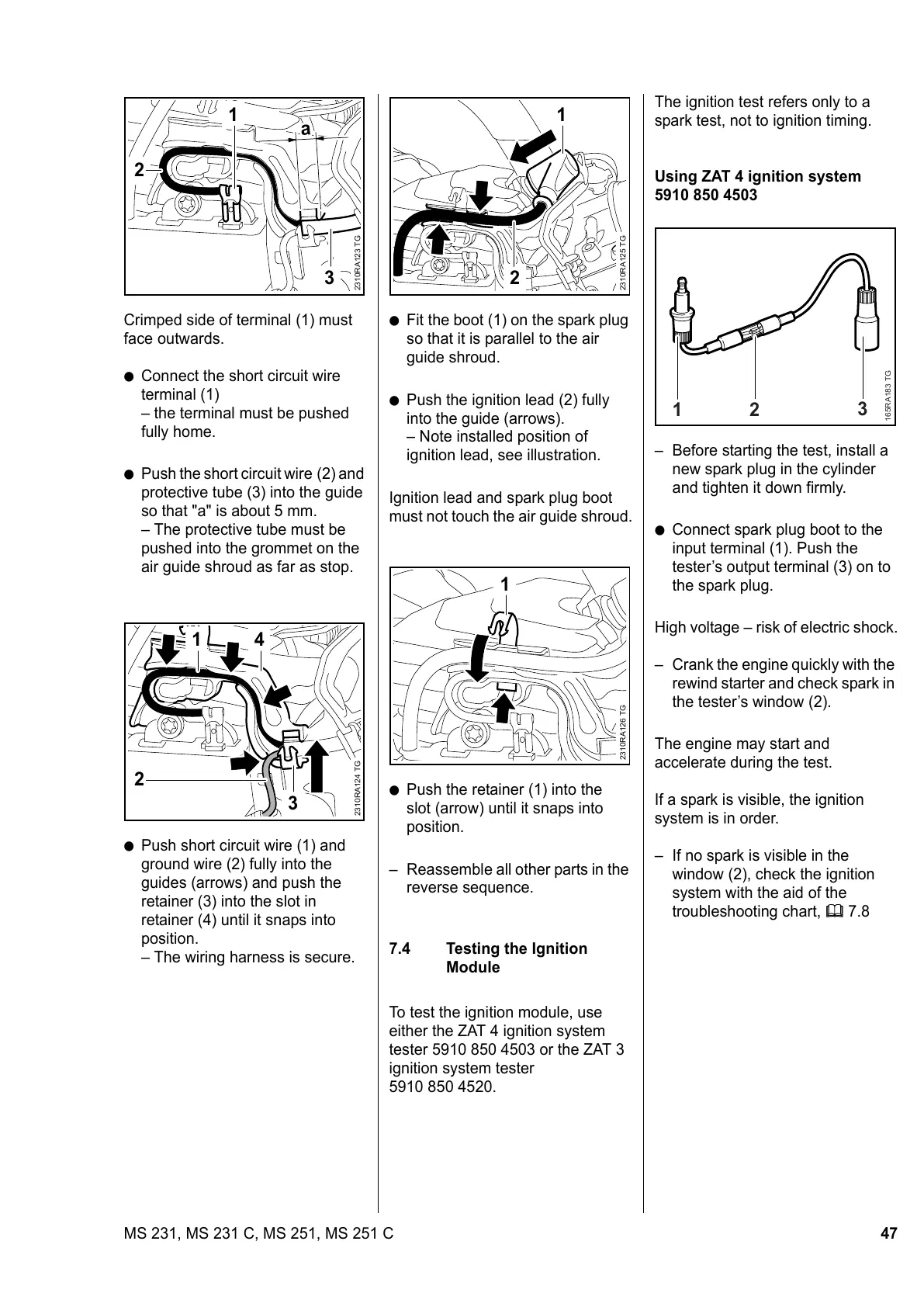

7.4 Testing the Ignition

Module

To test the ignition module, use

either the ZAT 4 ignition system

tester 5910 850 4503 or the ZAT 3

ignition system tester

5910 850 4520.

2310RA125 TG

1

2

2310RA126 TG

1

The ignition test refers only to a

spark test, not to ignition timing.

Using ZAT 4 ignition system

5910 850 4503

– Before starting the test, install a

new spark plug in the cylinder

and tighten it down firmly.

: Connect spark plug boot to the

input terminal (1). Push the

tester’s output terminal (3) on to

the spark plug.

High voltage – risk of electric shock.

– Crank the engine quickly with the

rewind starter and check spark in

the tester’s window (2).

The engine may start and

accelerate during the test.

If a spark is visible, the ignition

system is in order.

– If no spark is visible in the

window (2), check the ignition

system with the aid of the

troubleshooting chart, b 7.8

165RA183 TG

1

2

3

Loading...

Loading...