-

64

-

15-5 POWER TRANSMISSION TO DRIVE MACHINES

15-5-1 BELT DRIVE

Note the following:

●

Use a V-belt rather than a flat belt.

●

The drive shaft of the engine must be parallel to the drive shaft of the driven machine.

●

The drive pulley of the engine must be in line with the driven pulley of the machine.

●

Install the engine pulley as close to the engine as possible.

●

If possible, span the belt horizontally.

●

Disengage the load when starting the engine.

*

A belt tensioner or similar should be installed if no clutch is used.

15-5-2 FLEXIBLE COUPLING

When using a flexible coupling, run-out and misalignment between the driven shaft and the engine shaft

should be minimized.

The permissible margin of run-out and misalignment is specified by the flexible coupling manufacturer.

15-5-3 BELT PULLEY INSTALLATION ONTO

KEYWAY-TYPE CRANKSHAFT

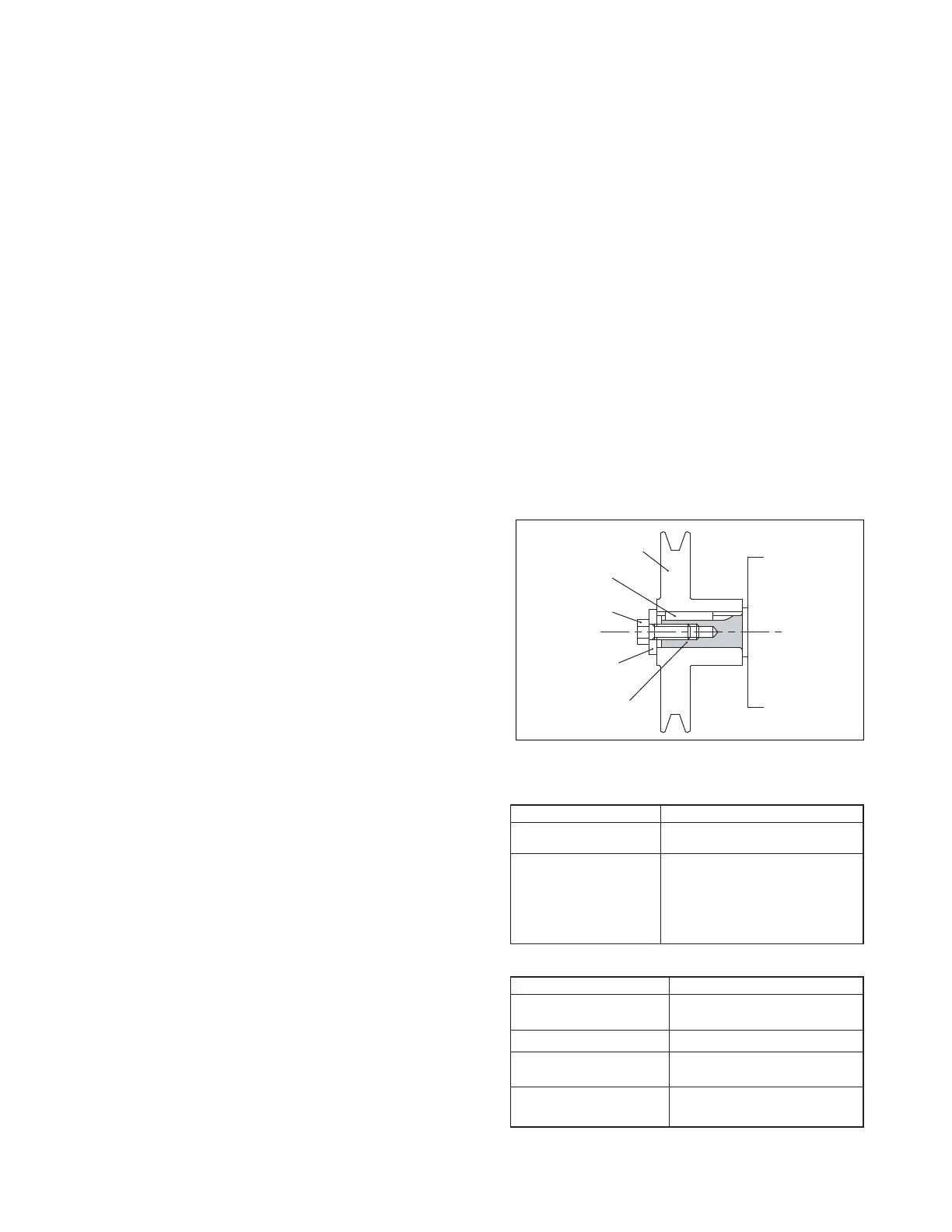

When installing the belt pulley and/or clutch onto

keywaytype crankshaft (PTO shaft), proper and

correct arrangements are needed. The following

illustration shows the correct installation of the

applicable component parts.

■

Metric keyway-type crankshaft

Washer; Use the washer (material; SS41P) with the

thickness described below;

Bolt; Select the proper bolt and tighten it to the

specified tightening torque, as mentioned

below;

Pulley

Bolt

Washer

PTO shaft

Key

Fig.15-1

EX35/40

020-01002-20, Washer

6.0

40

10.5

SS41P

6.0 or over

Washer Thickness

ROBIN genuine part

mm

Thickness; mm

OD;

mm

ID;

mm

Material;

“8T” or higher

Effective thread length

Strength

EX35/40

18 to 27

40 - 50

(408 - 510)

011-01003-00, Flange Bolt

30

(Screw length; mm)

ROBIN genuine parts

Tightening Torque

mm

N•m(kgf•cm)

Loading...

Loading...