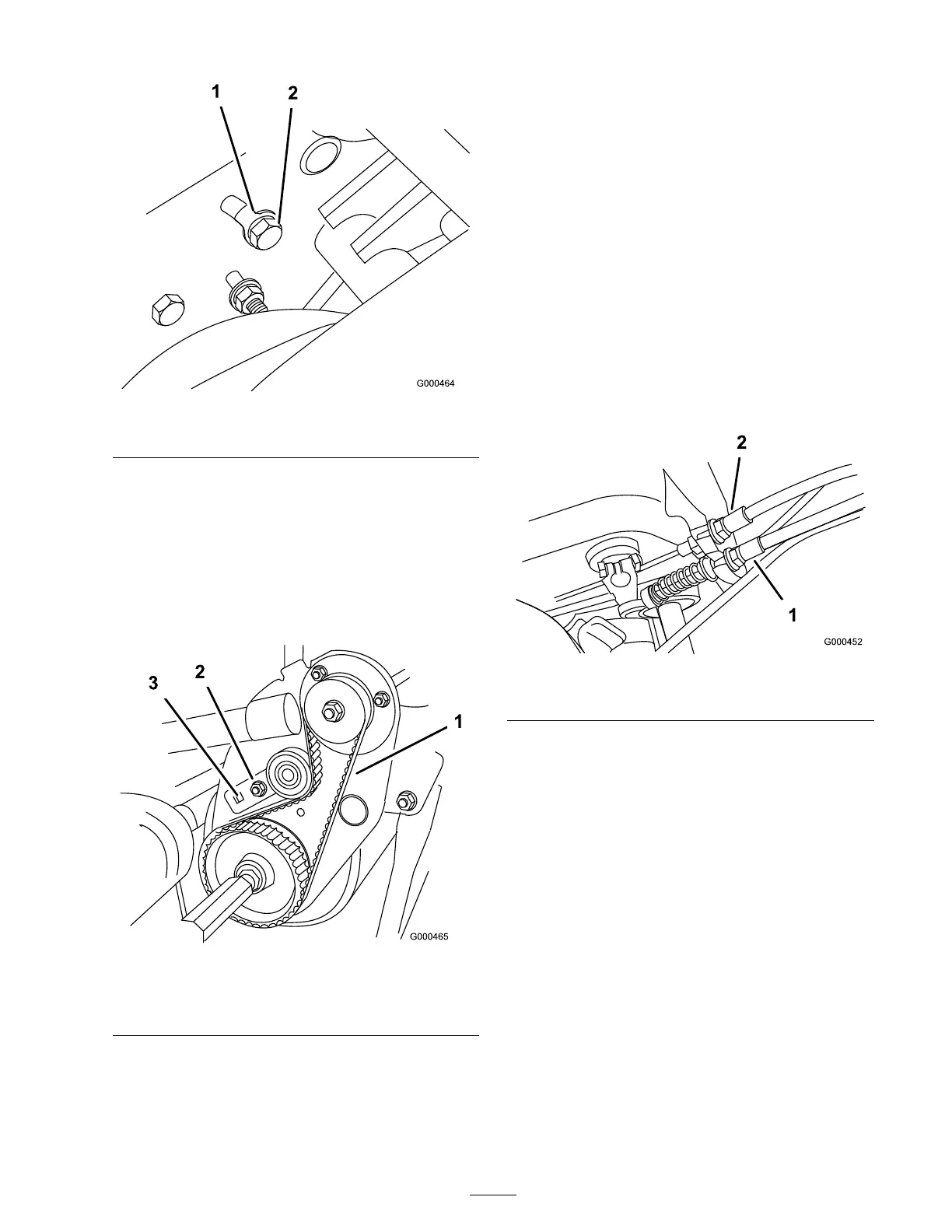

Figure 42

1. Tang washer 2. Idler bracket bolt

B . Using a 3/8 inc h dri v e tor que wrenc h,

rotate the idler brac k et with 35-40 in.-lb . of

tor que to set the belt tension ( Figure 43 ).

W hile holding the tor que wrenc h setting,

tighten the idler brac k et mounting bolt

(T he tang w asher is installed to prev ent the

belt from slipping .). Do not o v er -tension

the belt.

Figure 43

1. Traction drive belt 3. 3/8 inch Torque wrench

here

2. Idler bracket

C . Install the belt co v er .

Controls System

Maintenance

Adjusting the Traction

Control

If traction control does not eng ag e or it slips

during operation, an adjustment is required.

1. Mo v e traction control to Diseng ag ed position.

2. T o increase cable tension, loosen front cable

jam n ut and tighten bac k cable jam n ut

( Figure 44 ) until a force of 12-16 lb . is required

to eng ag e traction control.

Measure the force at the control knob .

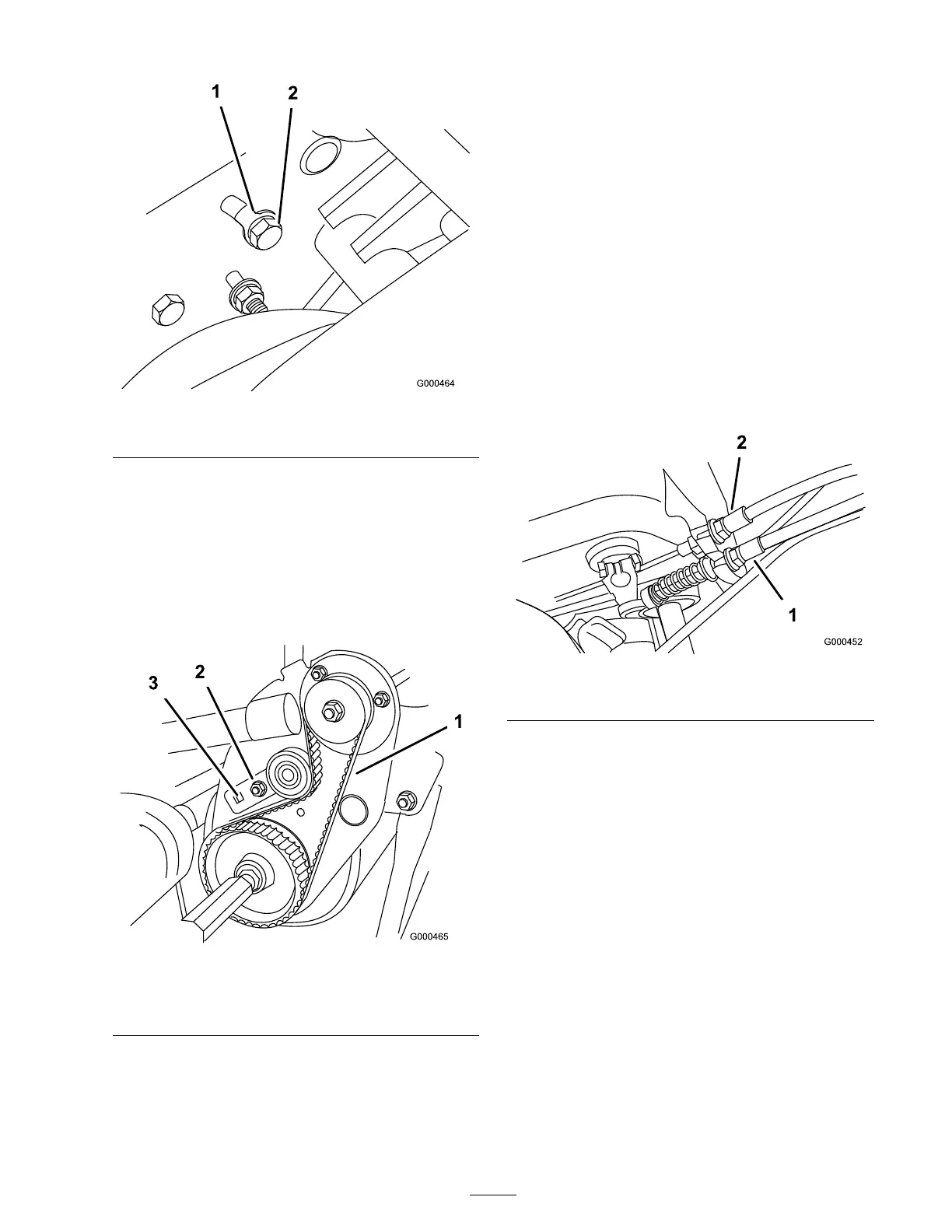

Figure 44

1. Traction cable 2. Service/parking brake cable

3. Tighten front cable jam n ut.

4. Chec k control operation.

Adjusting the Reel Control

If reel control does not eng ag e or it slips during

operation, an adjustment is required.

1. Mak e sure traction control is properly adjusted;

refer to Adjusting the T raction Control.

2. T o increase cable tension, loosen front cable

jam n ut and tighten bac k cable jam n ut

( Figure 45 ) (located on top of g ear bo x)

until the reel cable force adds 7 to 10 lbs . of

additional handle force measured at the control

knob .

Note: If traction control handle force is

12 lbs ., the combined traction and reel force

should be 19 to 22 lbs .

31

Loading...

Loading...