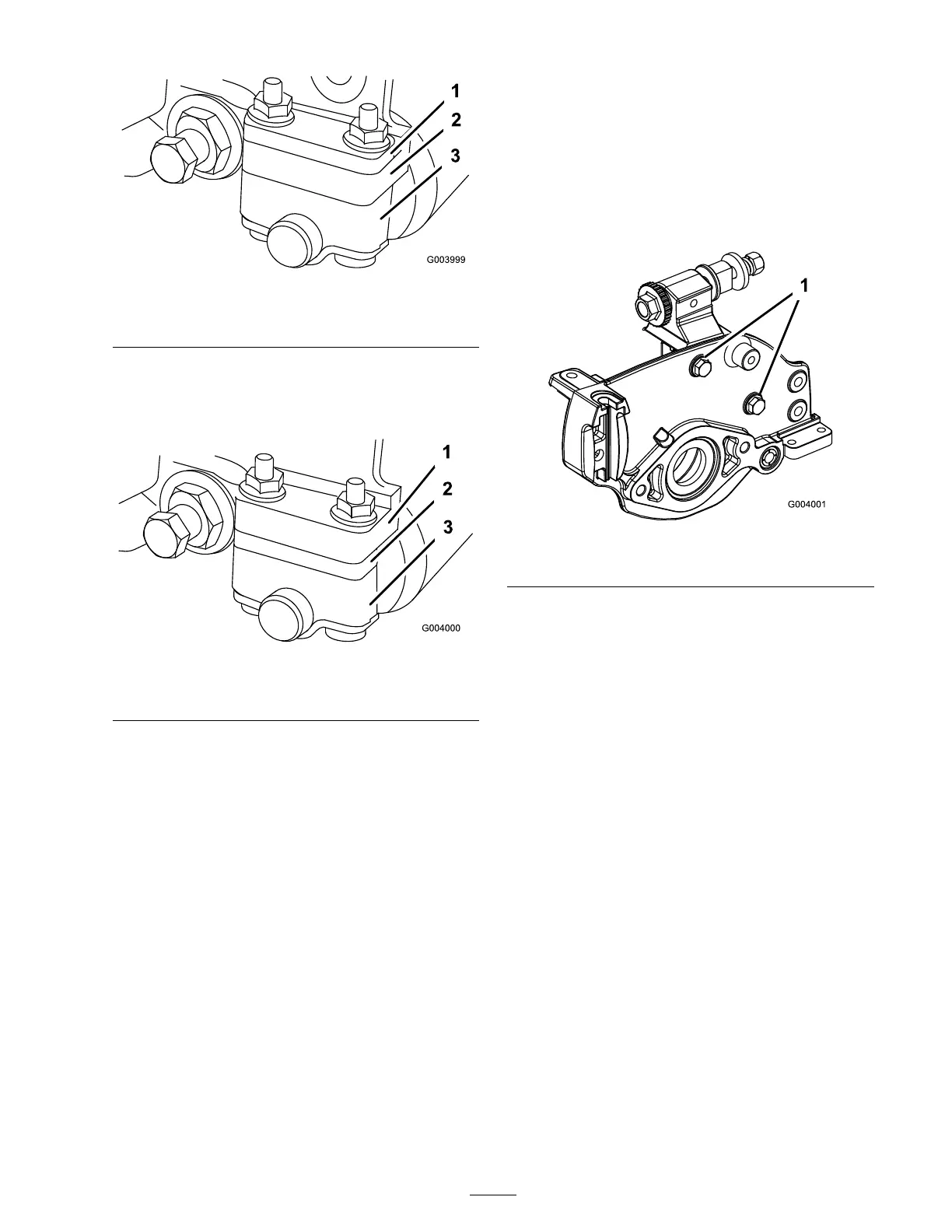

Figure 49

1. Spacer

3. Roller bracket

2. Sideplate mounting ange

• P osition the spacer belo w the side plate

mounting flang e when height of cut

settings rang e from 1/8" to 1" ( Figure 50 ).

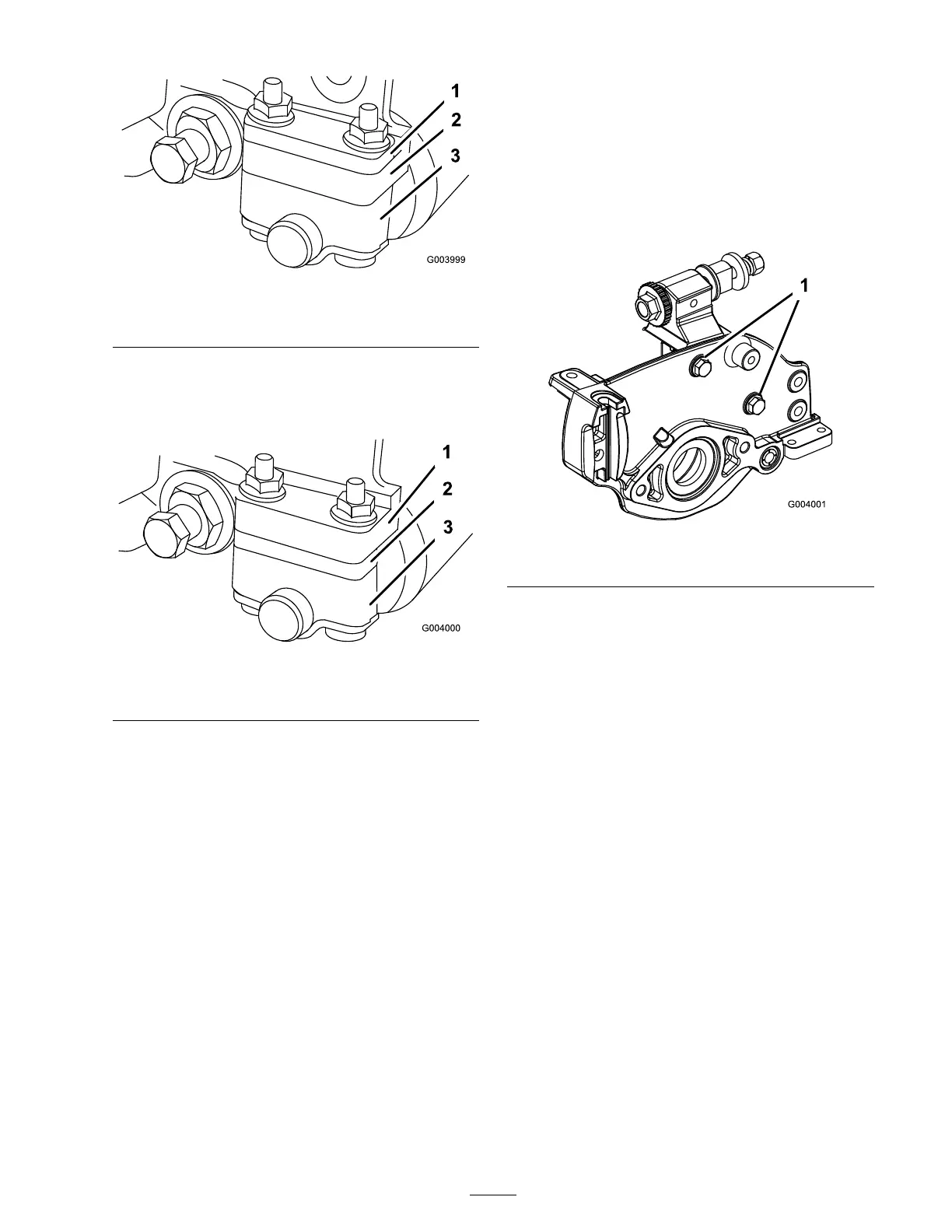

Figure 50

1. Sideplate mounting ange 3. Roller bracket

2. Spacer

2. T o adjust rear roller proceed as follo ws:

• Raise rear of cutting unit and place a bloc k

under bedknife .

• R emo v e (2) n uts securing eac h roller

brac k et and spacer to eac h side plate

mounting flang e .

• Lo w er roller and screws from side plate

mounting flang es and spacers .

• Place spacers onto screws on roller

brac k ets .

• R e-secure roller brac k et and spacers to

underside of side plate mounting flang es

with n uts previously remo v ed.

3. V erify that the bedknife to reel contact is

cor rect. Tip mo w er to expose front and rear

rollers and bedknife .

Note: T he position of the rear roller to the

reel is controlled b y the mac hining tolerances

of the assembled components and paralleling is

not required. A limited amount of adjustment

is possible b y setting the cutting unit on a

surface plate and loosening the side plate

mounting bolts ( Figure 51 ). Adjust and

re-tighten bolts .

Figure 51

1. Sideplate mounting bolts

Important: W henev er the cutting unit

has to be tipped to expose bedknife/r eel,

pr op up r ear of cutting unit to mak e sur e

n uts on back end of bedbar adjusting

scr ews ar e not r esting on w or k surf ace.

Adjusting the Bedknife to

the Reel

Bedknife to reel adjustment is accomplished b y

loosening or tightening bedbar adjusting screws ,

located on top of mo w er .

1. P osition mac hine on a flat, lev el w ork surface .

2. Mak e sure reel contact is remo v ed b y tur ning

bedbar adjusting screws countercloc kwise

( Figure 52 ).

33

Loading...

Loading...