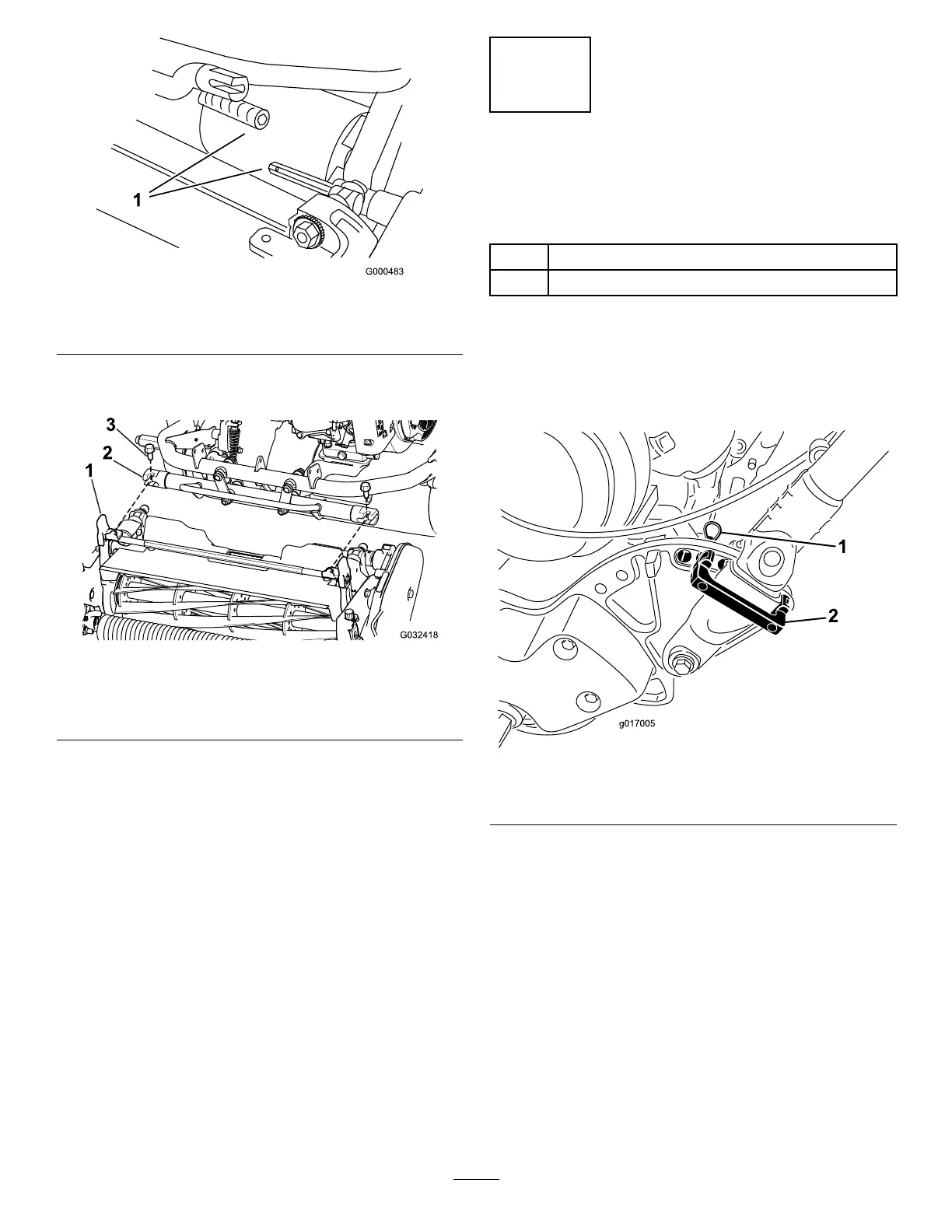

g000483

Figure6

1.Transmissioncoupling

4.Maneuverthemachineframeforwarduntilit

engagesthecuttingunitpivotarmsFigure7.

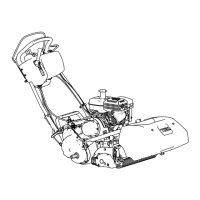

g032418

Figure7

1.Telescopingcoupler3.Bolt

2.Cutting-unithexshaft

5.Securethemachineframetothecuttingunit

pivotarmswiththe2bolts(3/8x3/4inch)

(Figure7).

6.MovethekickstandtotheSTORAGEposition

byreleasingthelockingpinandallowingthe

kickstandtorotateup.

7.Setthecutting-unitheightofcut;refertoyour

cuttingunitOperator’sManual.

3

InstallingtheHandle

Retainers

Partsneededforthisprocedure:

2Handleretainer

2Hairpincotter

Procedure

1.Whilesupportingthehandle,removethecable

tiesthatsecurethehandleclampstotheside

plates(Figure8).

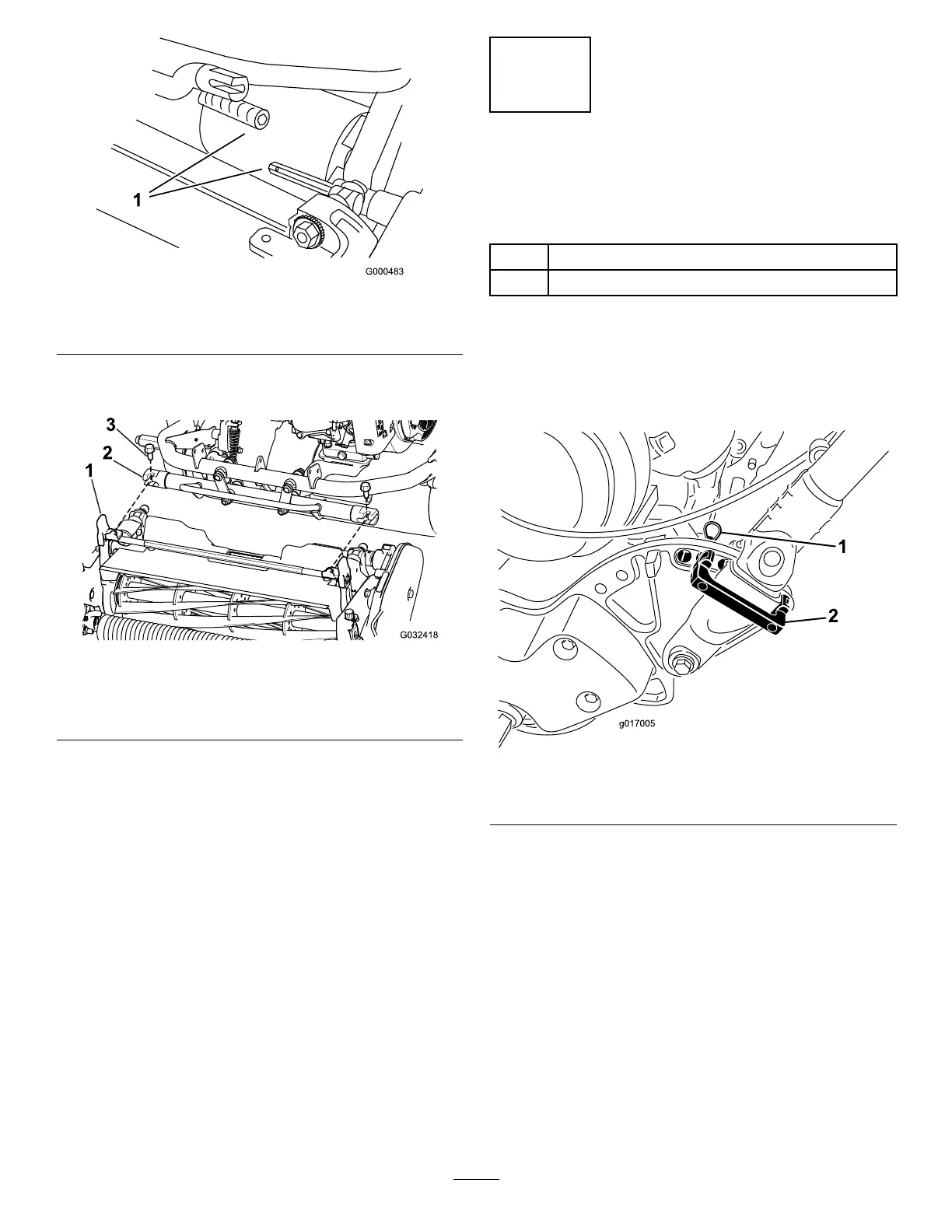

g017005

Figure8

1.Hairpincotter2.Handleretainer

2.Pivotthehandletothedesiredoperatingposition

andinsertahandleretaineroverthehandle

clampandintothematchingholesintheside

plate(Figure8).

3.Securetheclampinpositionwithahairpincotter

(Figure8).

4.Repeattheprocedureontheoppositesideof

thehandle.

5.Adjustthehandleheighttothedesiredposition;

refertoAdjustingtheHandleHeight(page20).

Note:Themachineisshippedwiththehandle

adjustedtothelowestposition.Themachineis

traditionallyoperatedwiththehandletelescoped

outtoitsmaximumheight.

9

Loading...

Loading...