15

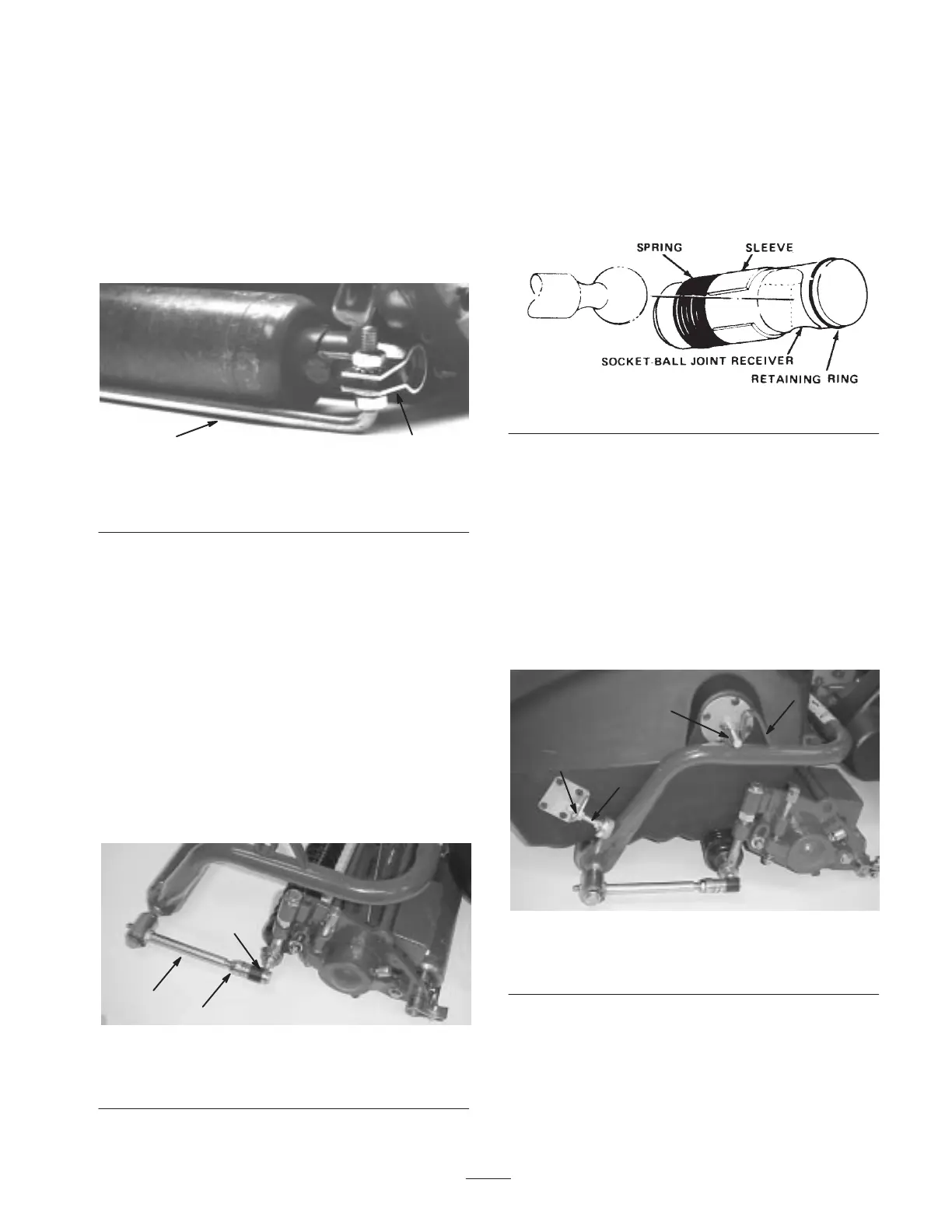

Adjust Rear Roller Scraper

The adjustment of the rear roller scraper depends on the

many conditions of the green (i.e. leaves, seeds, dew,

etc.).

1. Adjust scraper rod locknuts and brackets to attain

.06”–.10” clearance between scraper rod and roller

surface. Distance between bottom of rod and level

surface should be the same height as height-of-cut

setting.

1

2

Figure 14

1. Scraper rod 2. Bracket

2. Assure scraper rod is parallel to roller and level

surface.

Note: Readjust height of scraper rod if height-of-cut is

changed.

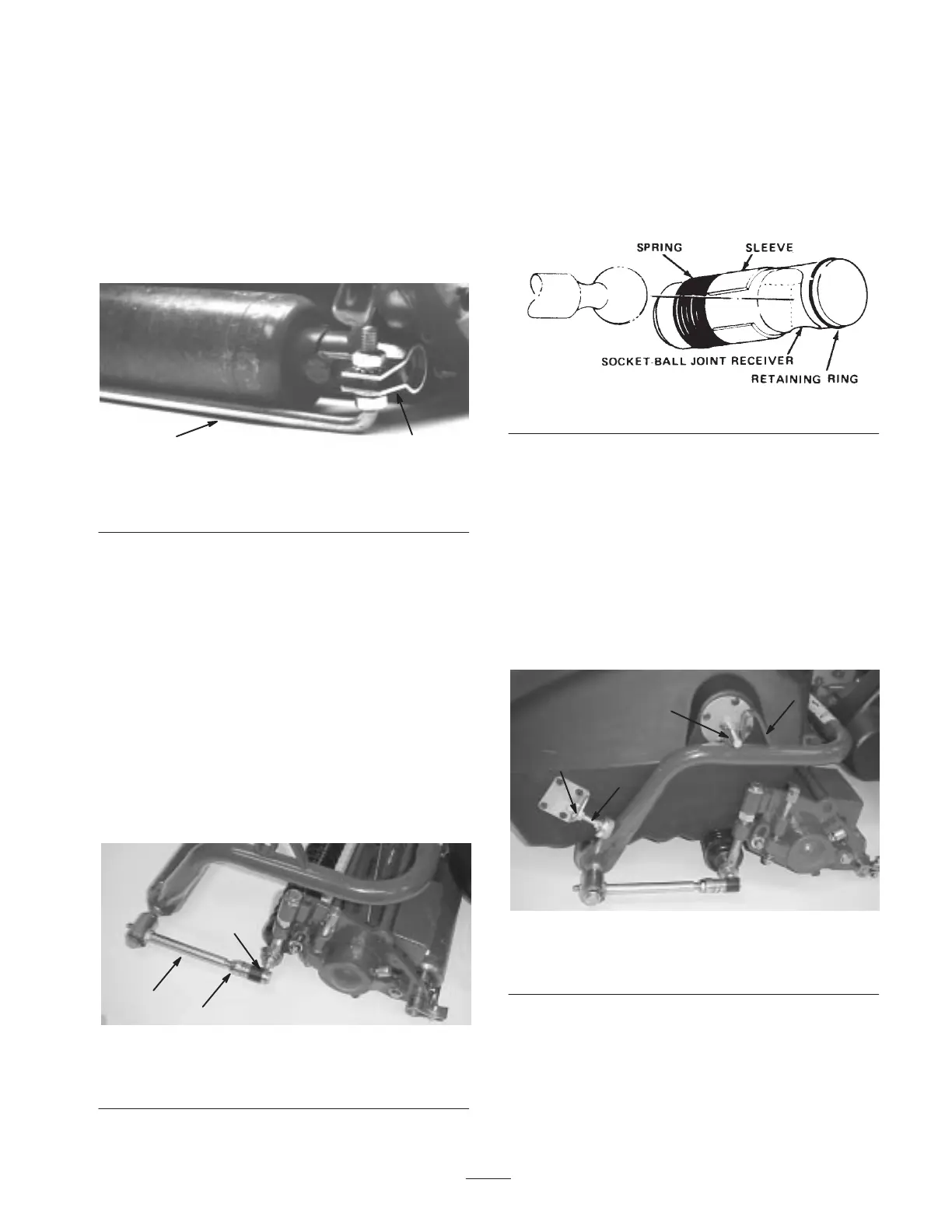

Check Cutting Unit Alignment

The cutting unit must be in alignment with the front yoke

roller so that the machine will track in a straight line

across the greens. The driveshaft must also be aligned

with the transaxle output shaft. If unit is not properly

aligned, use the following alignment procedures.

1. Loosen jam nut securing ball sockets to pull arms on

both side of the yoke (Fig. 15).

1

3

2

Figure 15

1. Jam nut

2. Ball socket

3. Pull arm

2. Slide sleeves back on each ball joint and rotate each

pull arm upward off the ball studs.

3. Align cutting unit with roller and driveshaft with

transaxle shaft and lengthen or shorten pull rods by

threading ball socket on rod (Fig. 15).

4. Align ball sockets with ball studs so hooded portion of

socket is at top and open side toward stud (Fig. 16).

Figure 16

5. Slide the sleeve back on the ball joint and rotate the

pull arm down so the socket fits over the ball stud.

Release the sleeve so it slids forward over the stud and

locks the assemblies together. Tighten the jam nuts to

secure the sockets in position (Fig. 16).

Install Grass Catcher

1. Set pins on basket pivots into brackets on yoke and

allow basket adjusting screw to rest onto yoke

(Fig. 17).

1

2

3

4

Figure 17

1. Basket pivot

2. Yoke bracket

3. Adjusting screw

4. Jam nut

2. Measure distance between lip of basket and edge of

cutting unit shield. There should be a clearance

between the components of no more than 1/4 inch

(6 mm) (Fig. 18). If the dimension is incorrect, adjust

basket.

Loading...

Loading...