CheckingtheHydraulic

LinesandHoses

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Getimmediatemedicalhelpifuidis

injectedintoskin.

•Ensurethatallhydraulicuidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

Checkthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operatingthemachine.

CheckingtheLeakDetector

Theleakdetectorsystemisdesignedtoassistinearly

detectionofhydraulic-uid-systemleaks.Iftheuid

levelinthemainhydraulicreservoirisloweredby

118to177ml(4to6oz),theoatswitchinthetank

willclose.Aftera1seconddelay,thealarmsounds,

alertingtheoperator(Figure48).Expansionofuid,

duetonormalheatingduringmachineoperation,

causestheuidtotransferintotheauxiliaryuid

reservoir.Theuidreturnstothemaintankwhenyou

turnofftheignitionswitch.

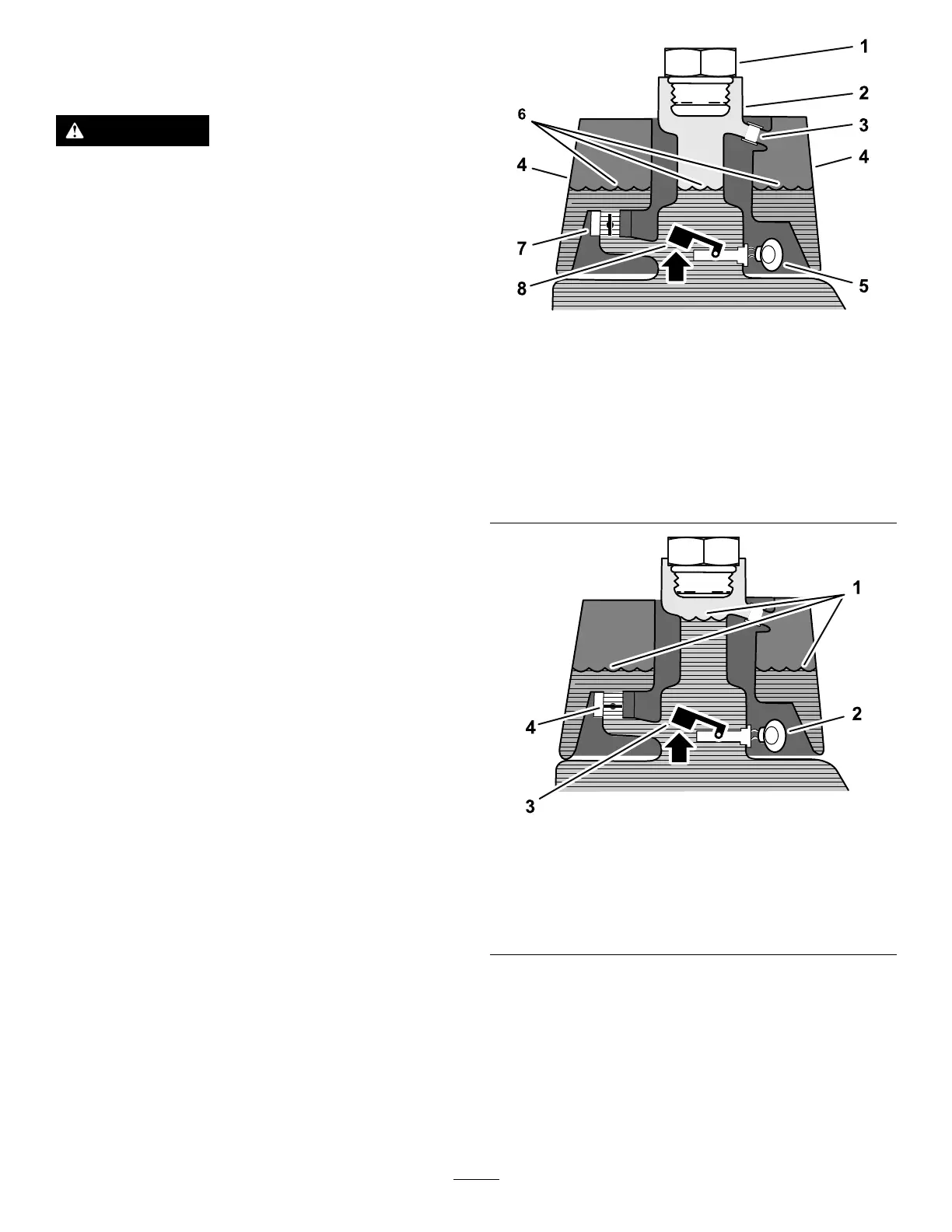

g229108

Figure46

BeforeStarting(uidcold)

1.Fillerplug5.Warningbuzzer—no

sound

2.Fillerneck

6.Fluidlevel(cold)

3.Overowtube7.Solenoid-returnvalve

(open)

4.Leak-detectortank8.Floatswitch

(raised—open)

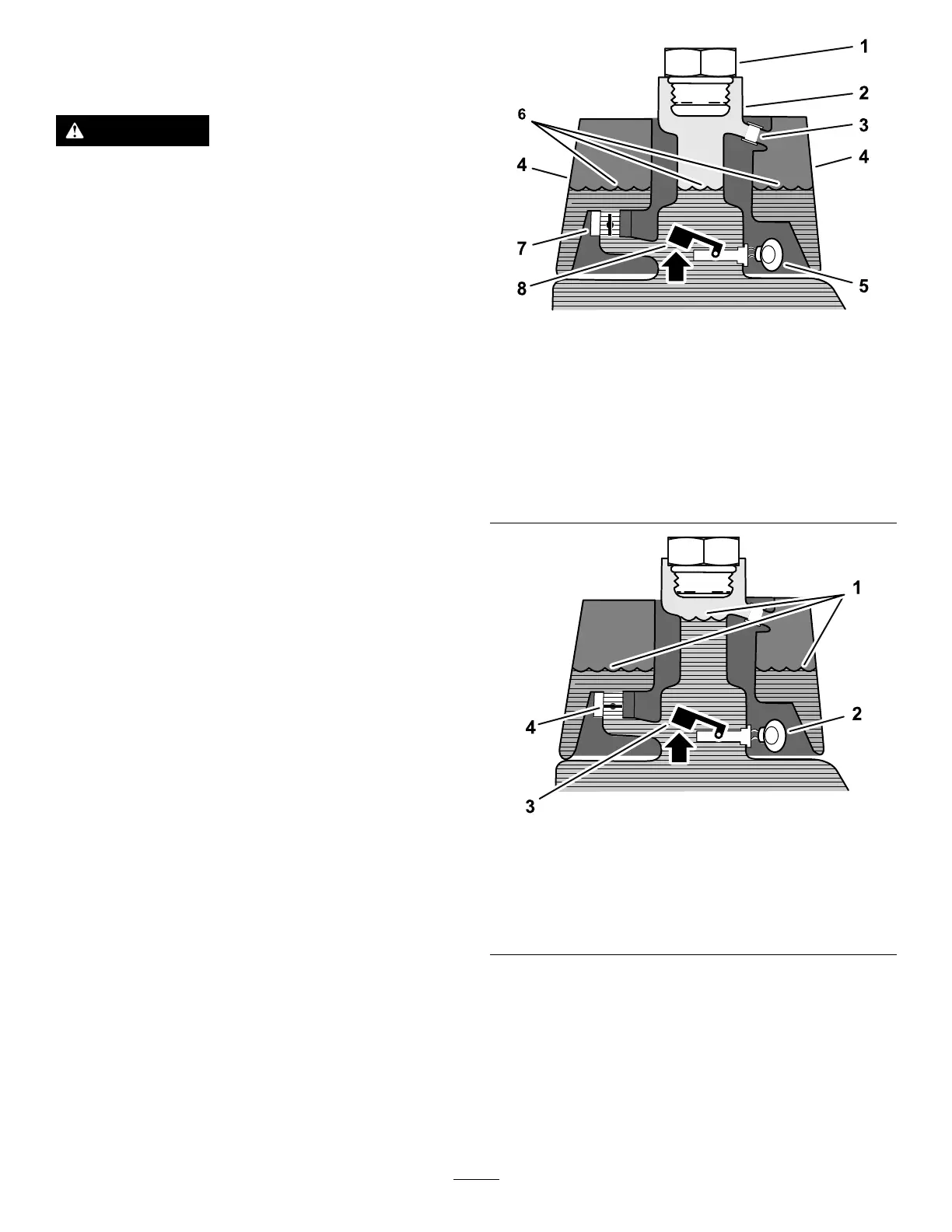

g229109

Figure47

NormalOperation(uidwarm)

1.Fluidlevel(warm)

3.Warningbuzzer

2.Solenoid-returnvalve

(closed)

4.Floatswitch

(raised—open)

45

Loading...

Loading...