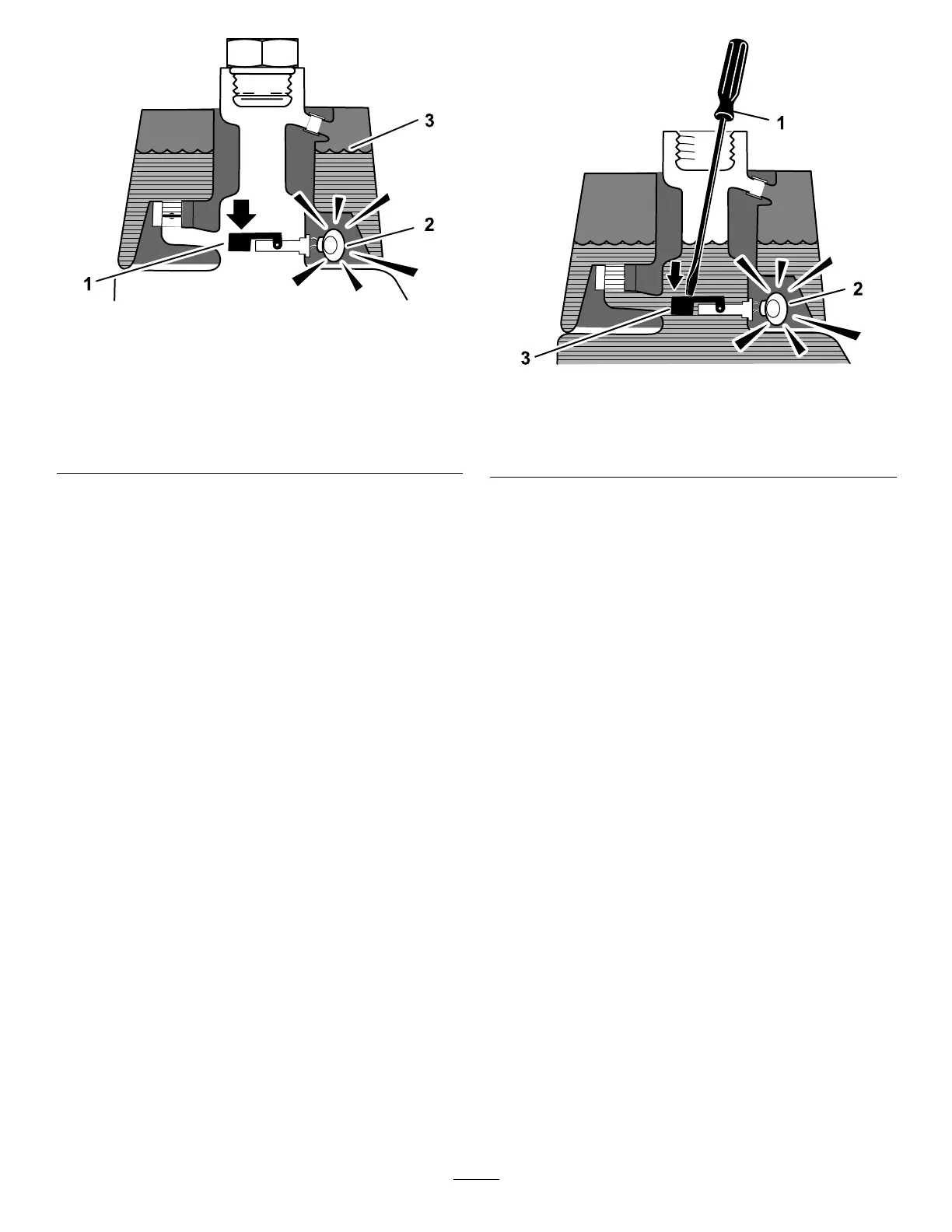

g229110

Figure48

LeakAlert!

1.Floatswitch

(down—closed)

Fluidleveldown118

to177ml(4to6oz)

3.Fluidlevel(warm)

2.Warningbuzzer

CheckingtheSystemOperation

1.WithignitionswitchintheONposition,movethe

leakdetectorswitchrearwardandhold.After

the1-seconddelayelapses,thealarmshould

sound.

2.Releasetheleak-detectorswitch.

Checkingthe

Leak-Detector-SystemOperation

1.MovetheignitionswitchtotheONposition.Do

notstarttheengine.

2.Removethehydraulic-tankcapfromtheneck

ofthetank.

3.Insertacleanrodorscrewdriverintothetank

neckandgentlypushdownontheoatswitch

(Figure49);thealarmshouldsoundafterthe

1-seconddelay.

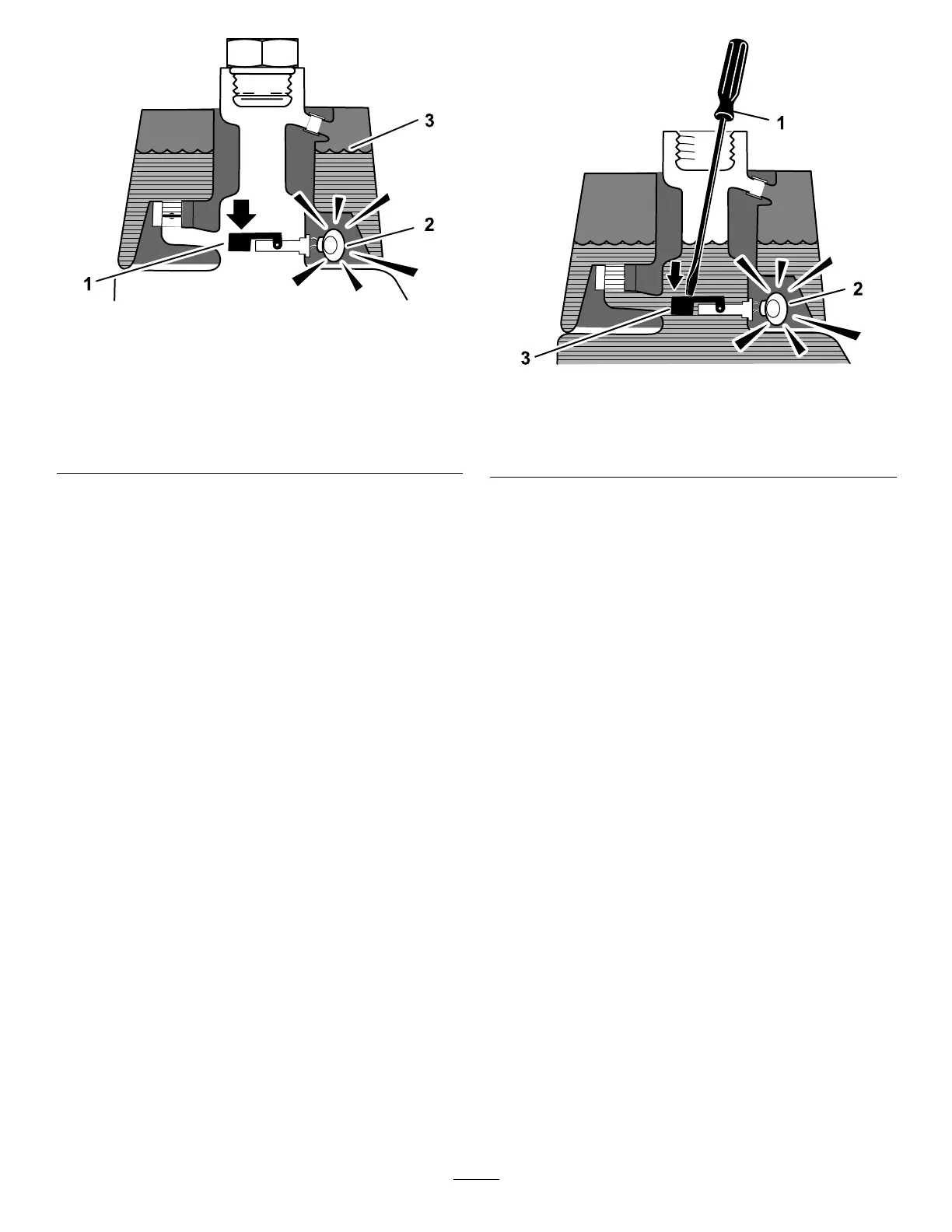

g229112

Figure49

1.Cleanrodorscrewdriver3.Pressdownontheoat

switch

2.Warningbuzzer

4.Releasetheoat;thealarmshouldstop

sounding.

5.Installthehydraulic-tankcap.

6.MovetheignitionswitchtotheOFFposition.

OperatingtheLeakDetector

Theleakdetectoralarmmaysoundfor1ofthe

followingreasons:

•Aleakof118to177ml(4to6oz)hasoccurred.

•Theuidlevelinthemainreservoirisreducedby

118to177ml(4to6oz)duetocontractionofthe

uidbycooling.

Ifthealarmsounds,turnoffthemachineasquicklyas

possibleandinspectitforleaks.Ifthealarmsounds

whileoperatingonagreen,driveoffthegreenrst.

Determinethesourceoftheleakandrepairitbefore

continuingoperation.

Ifyoudonotndaleakandsuspectafalsealarm,

movetheignitionswitchtotheOFFpositionandallow

themachinetostandfor1to2minutestoallowthe

uidlevelstostabilize.Thenstartthemachineand

operateitinanon-sensitiveareatoconrmthatno

leakexists.

Falsealarms,duetouidcontraction,maybecaused

byextendedidlingofthemachineafternormal

operation.Afalsealarmmayalsooccurifyouwork

themachineatareducedworkloadafteranextended

periodofaheavierworkload.T oavoidfalsealarms,

turnthemachineoffratherthanidlingforextended

periods.

46

Loading...

Loading...