19

2. Remove fuel tank cap.

Danger

Under certain conditions, diesel fuel and fuel

vapors are highly flammable and explosive. A fire

or explosion from fuel can burn you and others

and can cause property damage.

• Use a funnel and fill the fuel tank outdoors, in

an open area, when the engine is off and is cold.

Wipe up any fuel that spills.

• Do not fill the fuel tank completely full. Add fuel

to the fuel tank until the level is 1/4 to 1/2 in. (6

to 13 mm) below the bottom of the filler neck.

This empty space in the tank allows the fuel to

expand.

• Never smoke when handling fuel, and stay away

from an open flame or where fuel fumes may be

ignited by a spark.

• Store fuel in a clean, safety-approved container

and keep the cap in place.

3. Fill tank to about one inch below top of tank, (bottom of

filler neck). DO NOT OVERFILL. Then install cap.

4. Wipe up any fuel that may have spilled to prevent a fire

hazard.

1

Figure 9

1. Fuel tank cap

Check Transaxle / Hydraulic

Fluid

The transaxle reservoir is filled with Dexron IIl ATF. Check

level before engine is first started and every 8 hours or

daily, thereafter. Capacity of system is 7.5 qt.

1. Position the vehicle on a level surface.

2. Clean area around dipstick.

3. Unscrew dipstick from top of transaxle and wipe it with

a clean rag.

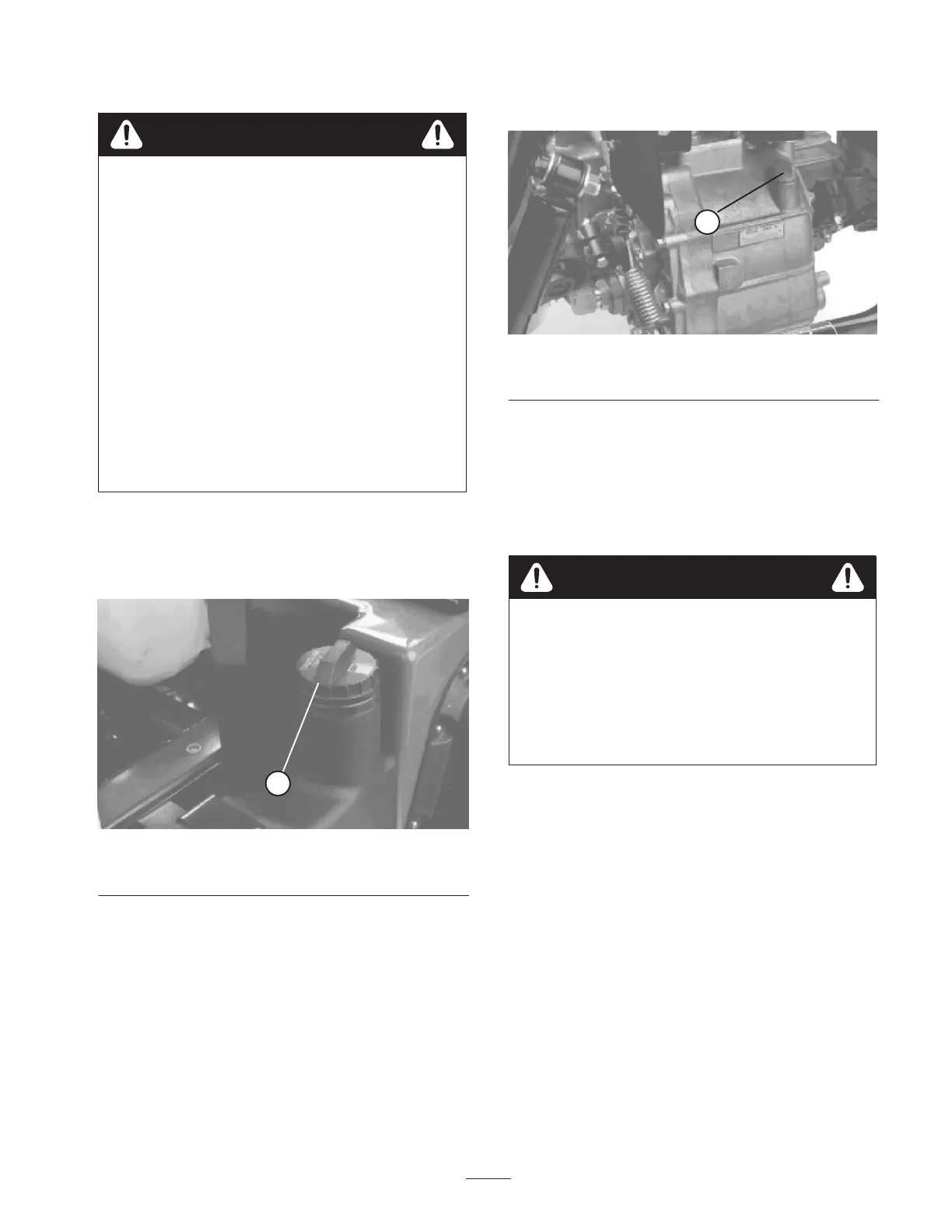

1

Figure 10

1. Dipstick

4. Screw dipstick into transaxle and make sure it is seated

fully. Unscrew dipstick and check fluid level. Fluid

should be up to top of flat portion of dipstick. If level is

low, add enough fluid to achieve the proper level.

Check Torque Of Wheel Nuts

Failure to maintain proper torque of the wheel

nuts could result in failure or loss of wheel and

may result in personal injury.

Torque the front and rear wheel nuts to

55–75 ft.-lb. after 1–4 hours of operation and again

after 10 hours of operation. Torque every 200

hours thereafter.

Warning

Check Tire Pressure

Check tire pressure every 8 hours or daily to assure proper

levels.

Maximum air pressure in front and rear (23”) tires is 20 psi.

1. The air pressure needed is determined by the payload

carried.

2. The lower the air pressure, the less the compaction and

tire marks are minimized. Lower pressure should not be

used for heavy payloads at high speeds. Tire damage

may result.

3. Higher pressures should be used for heavier payloads at

higher speeds. Do not exceed the maximum pressure.

Loading...

Loading...