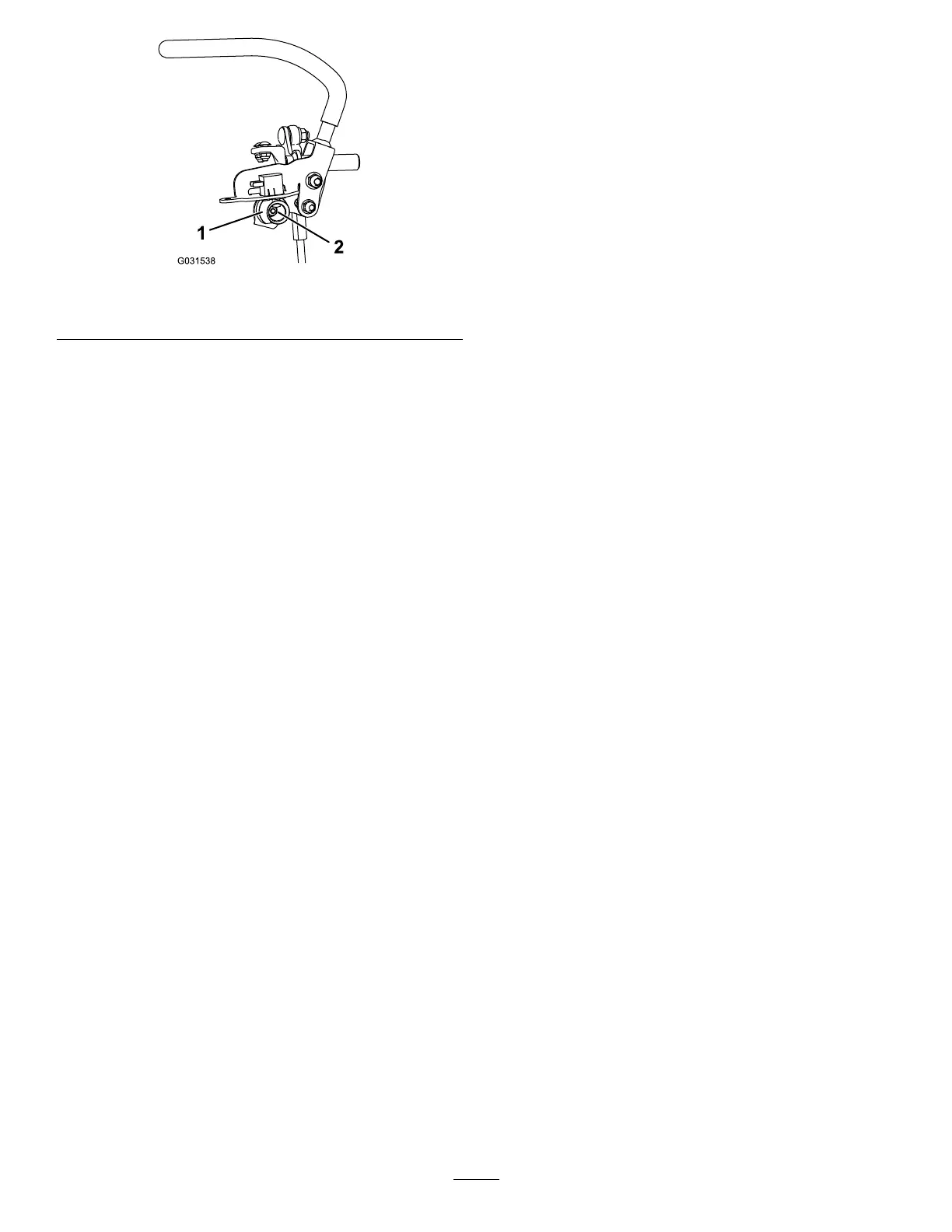

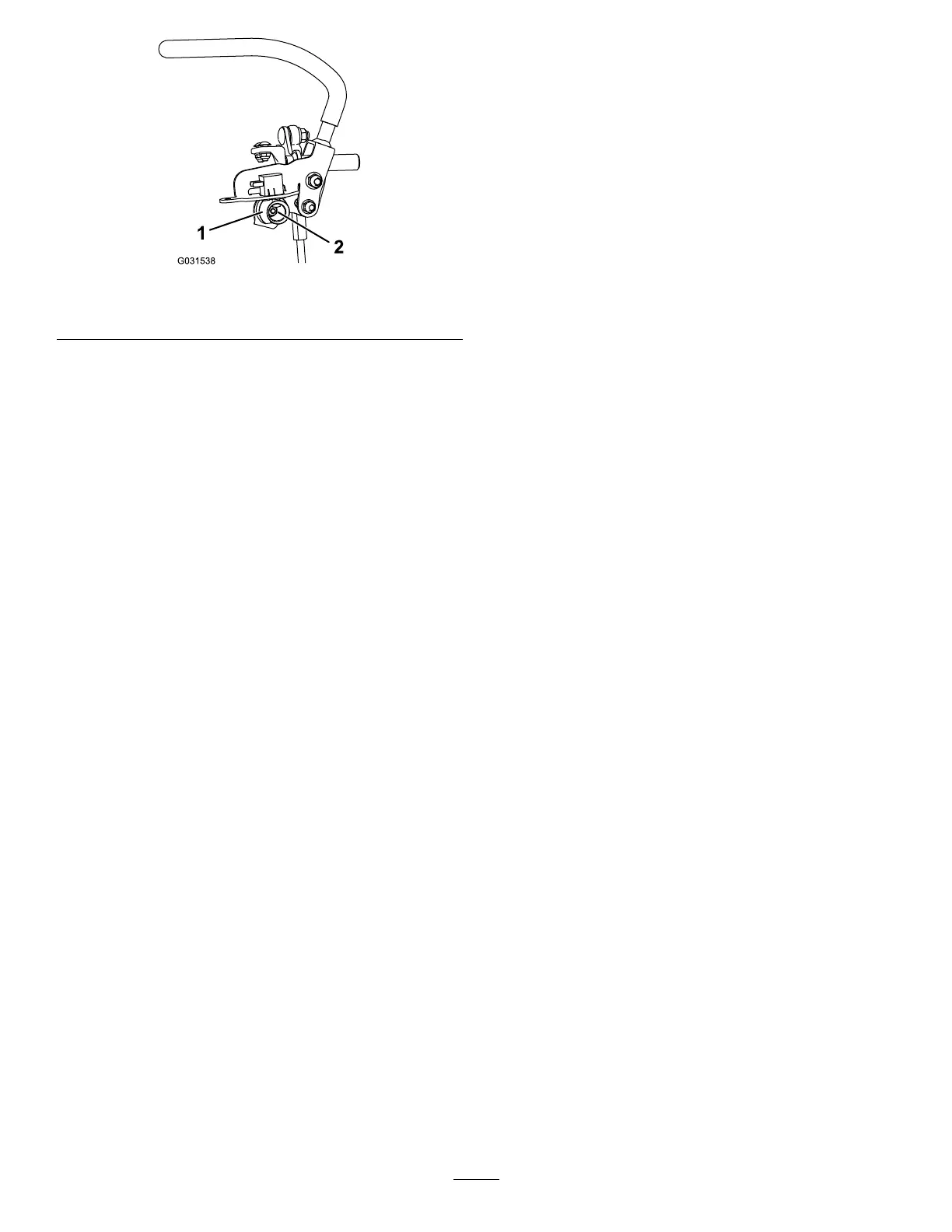

g031538

Figure73

1.Cam

2.Nut

7.Adjustthecamuntilitalignswiththeleft

motion-controlleverandtightenthenutforthe

cam.

Note:Movingthecamclockwise(inthevertical

position)lowersthehandle;movingthecam

counterclockwise(intheverticalposition)raises

thehandle.

Important:Ensurethattheatportionofthe

camdoesnotgoaboveaverticalposition

(rightorleft);otherwiseyoumaydamagethe

switch.

8.Repeatsteps3through7fortheleft

motion-controllever.

HydraulicSystem

Maintenance

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

HydraulicSystem

Specications

HydraulicFluidType:Toro

®

HYPR-OIL

™

500

hydraulicuid

HydraulicSystemFluidCapacity:4.7L(159oz)

Important:Usetheuidspecied.Otheruids

coulddamagethesystem.

CheckingtheHydraulic

Fluid

ServiceInterval:Aftertherst8hours

Every50hours

Note:Checkthehydraulic-uidlevelwhentheuid

iscold.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Waitforthemachinetocool.

4.Cleantheareaaroundthecapandthellerneck

ofthehydraulictank(Figure74).

49

Loading...

Loading...