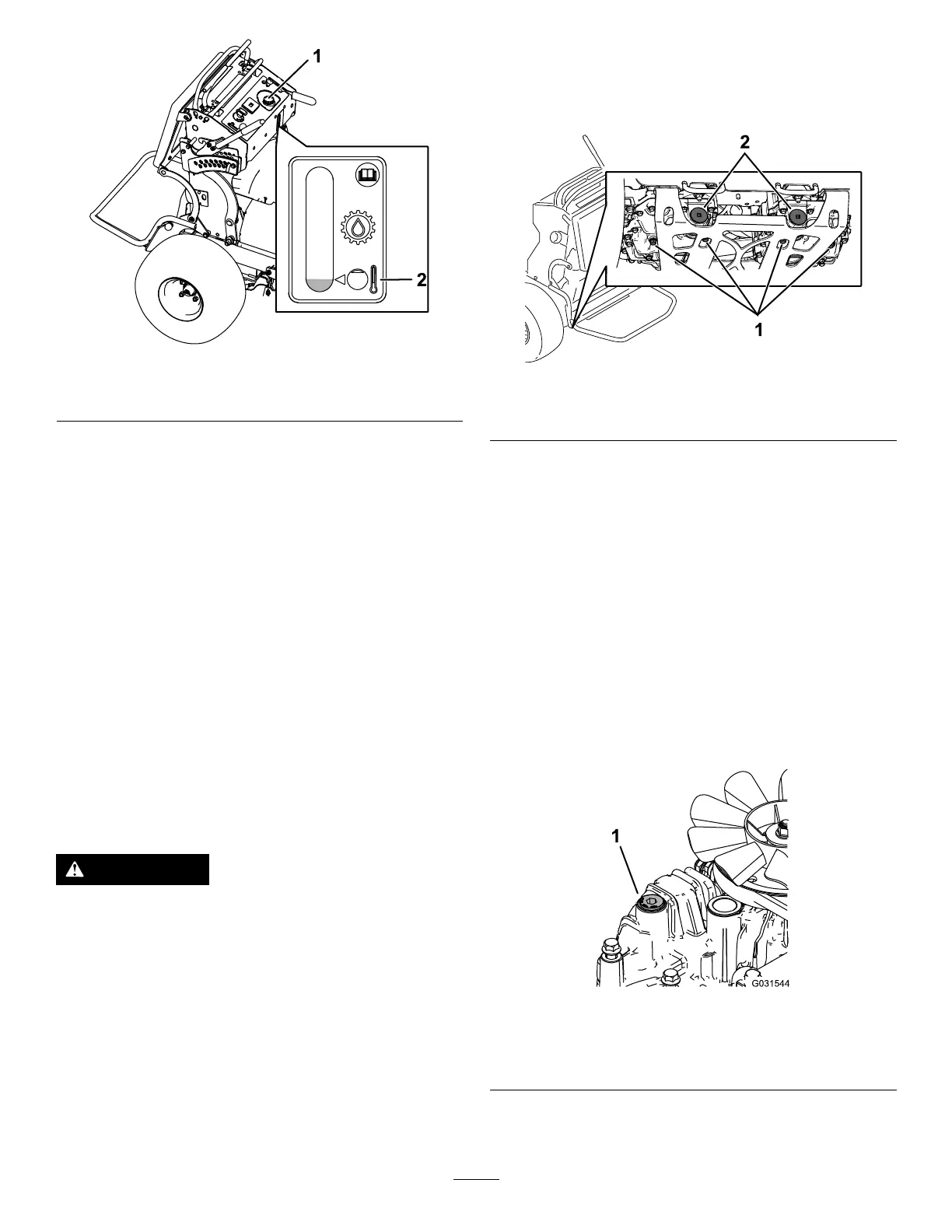

g301336

Figure74

1.Hydraulic-tankcap

2.Colduidlevel

5.Removethecapfromthellerneck(Figure74).

Note:Lookinsidetochecktheuidlevelin

thereservoir.

6.Adduidtothereservoiruntilitreachesthe

reachestheminimumcoldlllevel.

7.Installthecaponthellerneck.

ReplacingtheHydraulic

FluidandFilters

ServiceInterval:Aftertherst50hours

Every500hours/Yearly(whichevercomes

rst)—Changethehydraulicltersandhydraulic

uid.

Changethehydraulicuidmorefrequentlyinsevere

conditionsorinahotoperatingclimate.Contact

yourAuthorizedServiceDealerforahydraulickitto

replacethehydrauliclters.

WARNING

Hothydraulicuidcancausesevereburns.

Allowthehydraulicuidtocoolbefore

performinganymaintenanceonthehydraulic

system.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethefueltank;refertoRemovingthe

FuelT ank(page38).

4.Removethehydraulic-reservoircap.

5.Locatethedrainpluginthebottomofeach

transmissionandplaceadrainpanunderthe

plugs(Figure75).

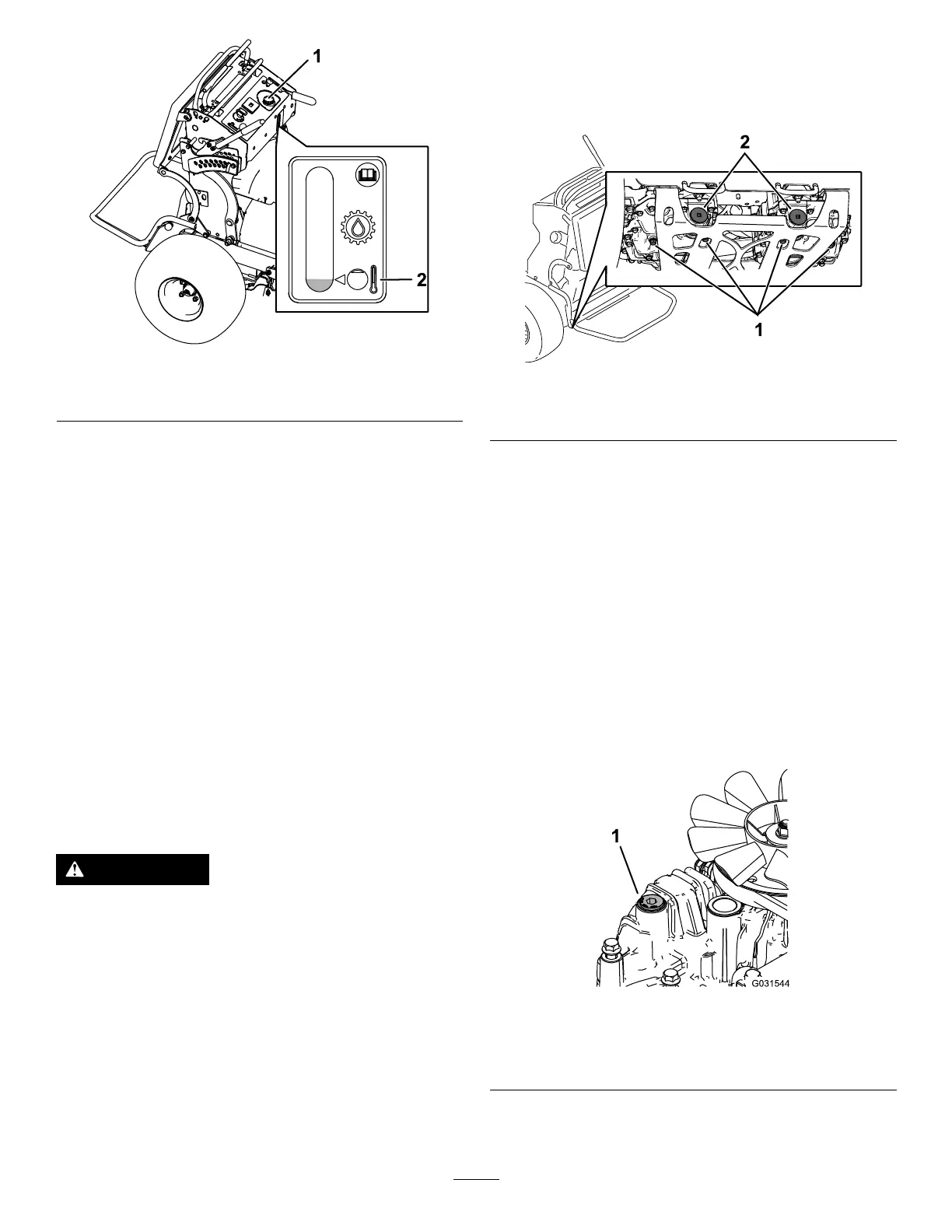

g268090

Figure75

1.Drainplug

2.Hydrauliclter

6.Removethedrainplugs.

7.Allowthehydraulicuidtofullydrainfromthe

machine.

8.Removethehydraulicltercapandlterfrom

eachtransmission.

9.Installnewhydrauliclterswiththespringside

facingoutandinstalltheltercaps.

10.Installthedrainplugsandtorqueto22to27

N∙m(16to20ft-lb).

11.Loosentheventplugineachtransmissionso

thatitislooseandwobbles(Figure76).

Note:Thisallowsairtoescapethehydraulic

systemasyouaddhydraulicuid.

g031544

Figure76

Lefttransmissionshown

1.Ventplug

12.Slowlyadduidtothehydraulictankuntilit

startstocomeout1oftheventplugs.

50

Loading...

Loading...