Groundsmaster 4500 --D/4700--D Hydraulic SystemPage 4 -- 113

For solenoid and control valve service procedures, see

Control Manifold Cartridge Valve Service in this section.

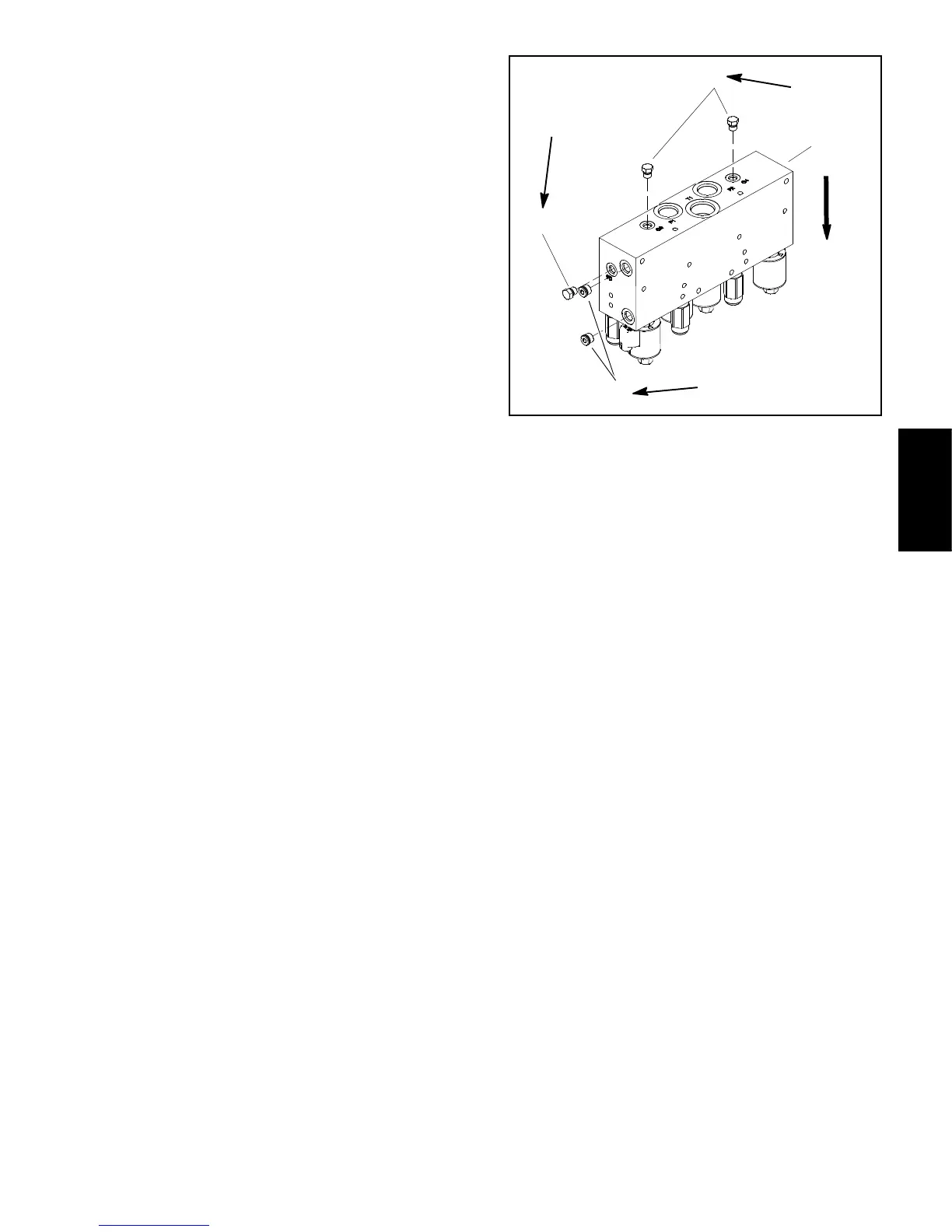

Refer to Figures 95 and 96 for cartridge valve and plug

installation torque.

IMPORTANT: A pilot piston (item 6) is placed be-

neath each of the relief valves in deck control man-

ifold ports RV8, RV9, RV10 and RV11. If a relief valve

is removed from the manifold, make sure to remove

pilot piston and label its position for assembly pur-

poses. When installing the pilot piston in the man-

ifold, make sure that the pilot piston slides fully into

the port before installing relief valve.

1. Manifold body

2. Zero leak plug (#6)

3. Zero leak plug (#4)

Figure 96

1

3

2

UP

2

25 ft--lb

(34 N--m)

20 ft--lb

(27 N--m)

20 ft--lb

(27 N--m)

Hydraulic

System