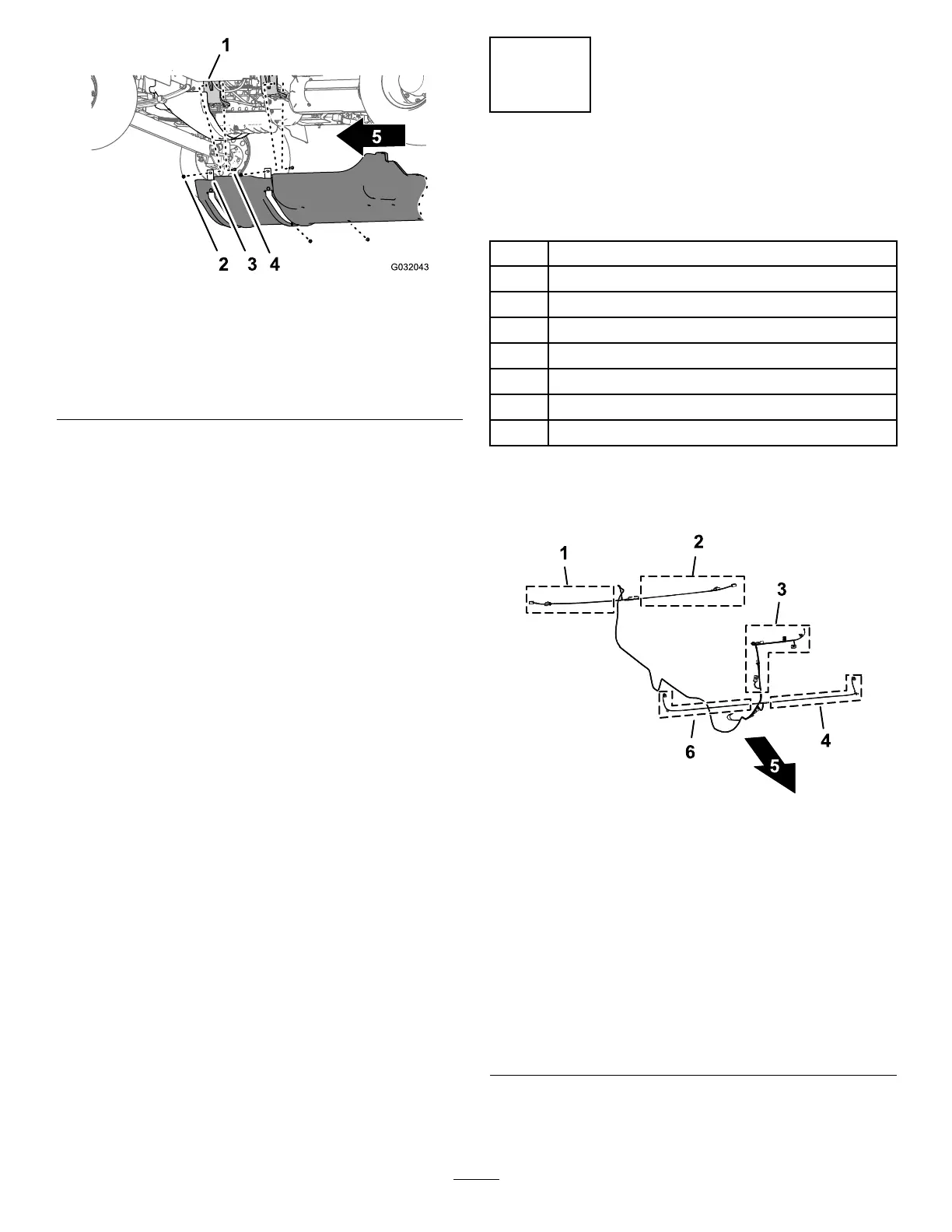

g032043

Figure6

1.Enginemounts

4.Flangelocknuts(5/16

inch)

2.Bolt—shownforclarity;do

notremove

5.Frontofthemachine

3.Undercarriageshroud

3.Liftthesupportstrapsovertheboltsthatsecure

theundercarriageshroudtotheengine-mount

brackets.

4.Removetheundercarriageshroudfromthe

machine(Figure5andFigure6).

3

AssemblingtheWorklight

andWireHarness

Partsneededforthisprocedure:

1WireHarness

1

Grommet

2Worklightmount

1

Supportchannel

4

Flange-headbolt(3/8x2-1/4inches)

4

Spacer

4

Flangelocknut(3/8inch)

2Worklight

AssemblingtheGrommetontothe

WireHarness

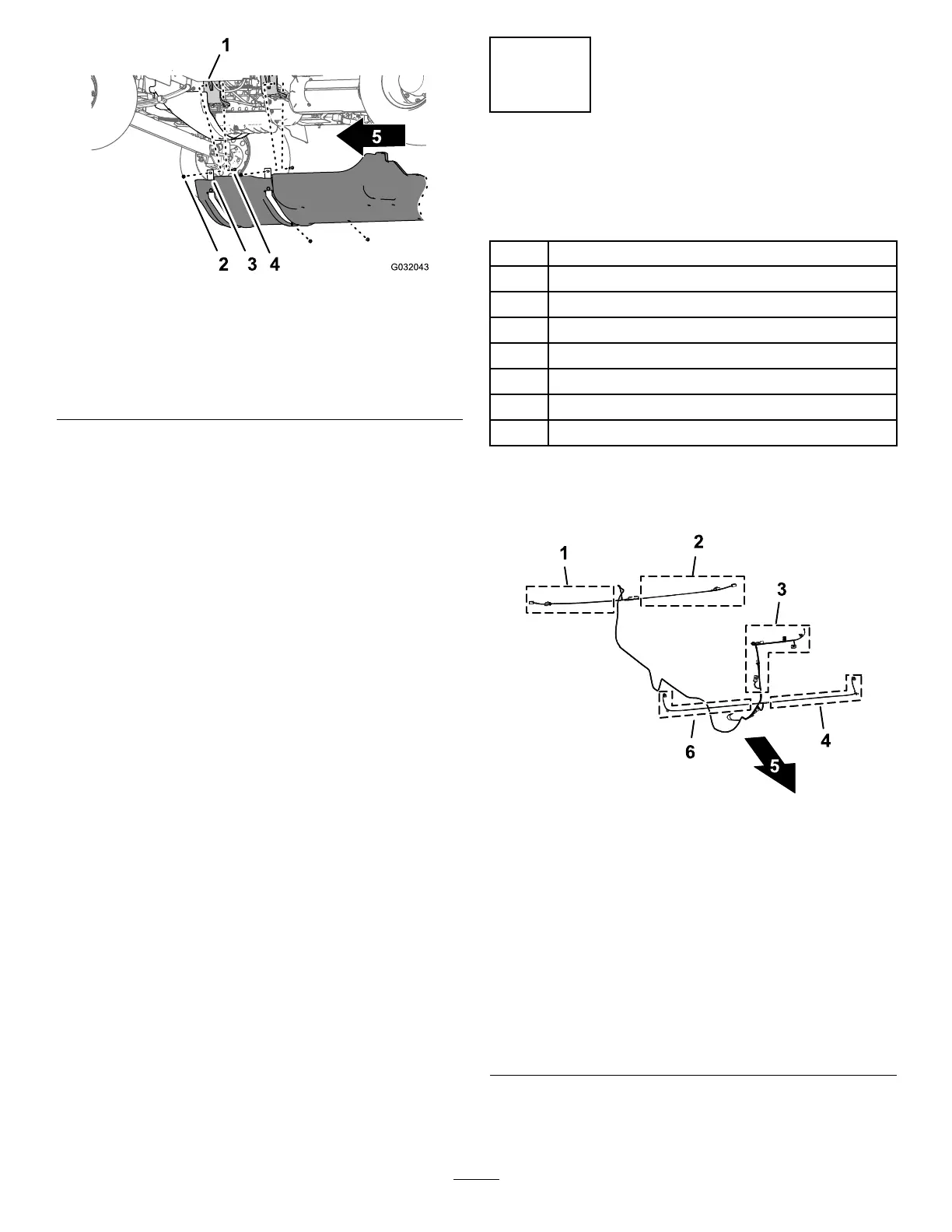

g207897

Figure7

1.71cm(28inches)wire

harnessbranch—RIGHT

TURNSIGNAL

4.99cm(39inches)wire

harnessbranch—LEFT

FRONTTURN/RUNNING

LIGHT

2.89cm(35inches)wire

harnessbranch—LEFT

TURNSIGNAL

5.Forward

3.108cm(42-1/2

inches)wireharness

branch—hornswitch,TO

HEADLIGHTSWITCHPIN1,

turnsignal,hazardswitch,

CEashermodule,andTO

MAINHARNESS

6.112cm(44inches)wire

harnessbranch—RIGHT

FRONTTURN/RUNNING

LIGHT

1.Alignthe6-socketconnectorfortheRIGHTFRONT

TURN/RUNNINGLIGHTofthe112cm(44inches)

wireharnessbranchthroughthegrommetand

5

Loading...

Loading...