DriveSystem

Maintenance

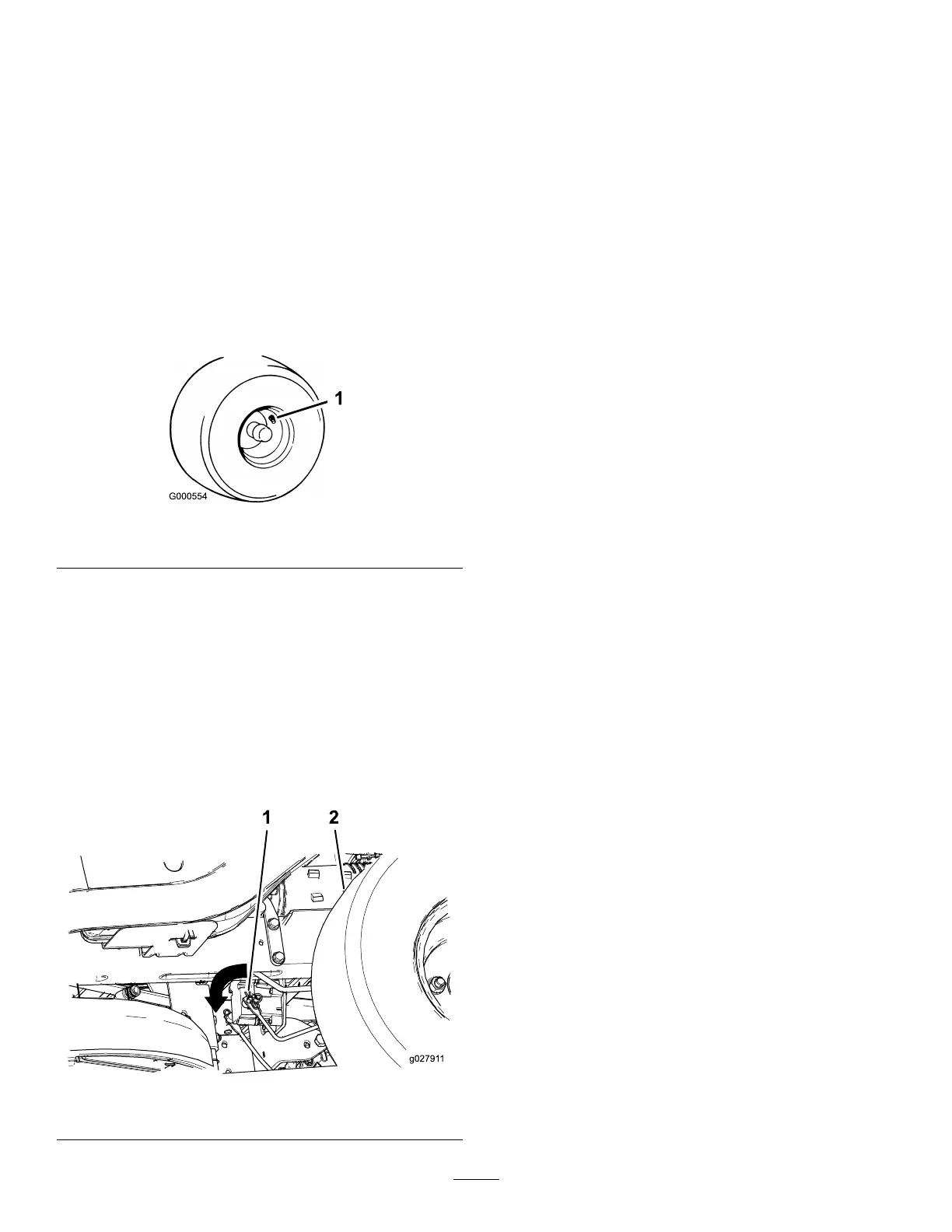

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure42).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto90kPa(13psi).

Figure42

1.Valvestem

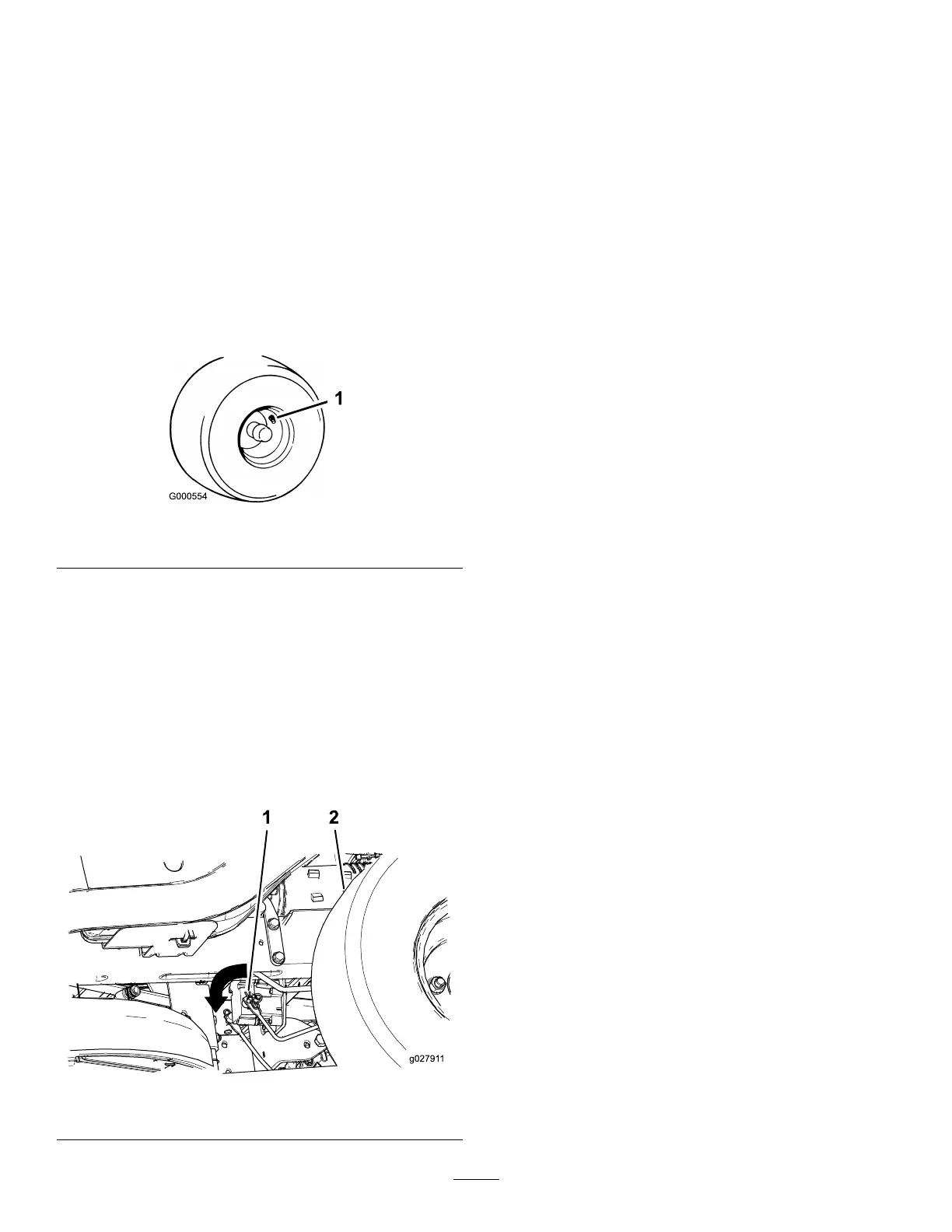

ReleasingtheElectricBrake

Theelectricbrakereleasesbymanuallyrotatingthelinkarms

forward.Oncetheelectricbrakeisenergized,thebrakewill

reset.

1.TurntheignitionkeytotheOFFpositionordisconnect

thebattery.

2.Locatetheshaftontheelectricbrakewherethe

brake-linkarmsareconnected(Figure43).

3.Rotatetheshaftforwardtoreleasethebrake.

Figure43

1.Brake-linkarmontheelectric-brake-controlmodule

CoolingSystem

Maintenance

CleaningtheEngineScreen

ServiceInterval:Beforeeachuseordaily—Cleantheengine

air-intakescreen.

Toensurepropercooling,ensurethatthegrassscreen,

coolingns,andotherexternalsurfacesoftheengineare

keptcleanatalltimes.

Useadrybrushtocleangrassandaccumulateddebrisfrom

theair-intakescreenandaroundtheengine.

Important:Topreventcontaminatingthefuelsystem,

donotusewatertocleantheengine.

CleaningtheEngine-Cooling

FinsandShrouds

ServiceInterval:Every100hours—Cleantheengine-cooling

nsandshrouds.

1.Disengagetheblade-controlswitch,movethecontrol

leverstotheNEUTRAL-LOCKposition,andapplythe

parkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheair-intakescreenandcoolingshrouds.

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installtheair-intakescreenandcoolingshrouds.

35

Loading...

Loading...