MaintenanceService

Interval

MaintenanceProcedure

Every100hours

•Cleanandlubricatetheundersideofthetractioncontrols.

•Removetheair-cleanercoverandcleanoutdebris.(Cleanmoreoftenindirtyor

dustyconditions.)

•Checkthecoolingsystemhoses.

•Adjustthealternatorbelttension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Checkfordirtbuildupinthechassis.

•Checkthealternator/fanbelttension(refertotheengineowner’smanualfor

instructions).

Every400hours

•Changetheengineoilandlter.(Servicemorefrequentlyifconditionsareextremely

dustyorsandy.)

•Replacethefuelltercanister.

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacethehydraulicoilandlters(ifnotusingTorouid).

Every500hours

•Replacingthewaterseparatorlter.

•Drainandcleanthefueltank(s)—AuthorizedServiceDealeronly.

•Replacethealternatorbelt—AuthorizedServiceDealeronly

•Replacethealternator/fanbelt(refertotheengineowner’smanualforinstructions).

Every800hours

•Changetheenginecoolant.

Every1,000hours

•Replacethedrive-motorplanetarygearoil.

•Replacethehydraulicoilandlters(ifusingT orouid).

Every1,500hours

•Replaceallmovinghydraulichoses.

Yearly

•Replacetheair-cleanerlter.

Yearlyorbeforestorage

•Checkandadjustthetracktension.

•Touchupchippedpaint.

Every2years

•Replaceallmovinghydraulichoses.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

Pre-Maintenance

Procedures

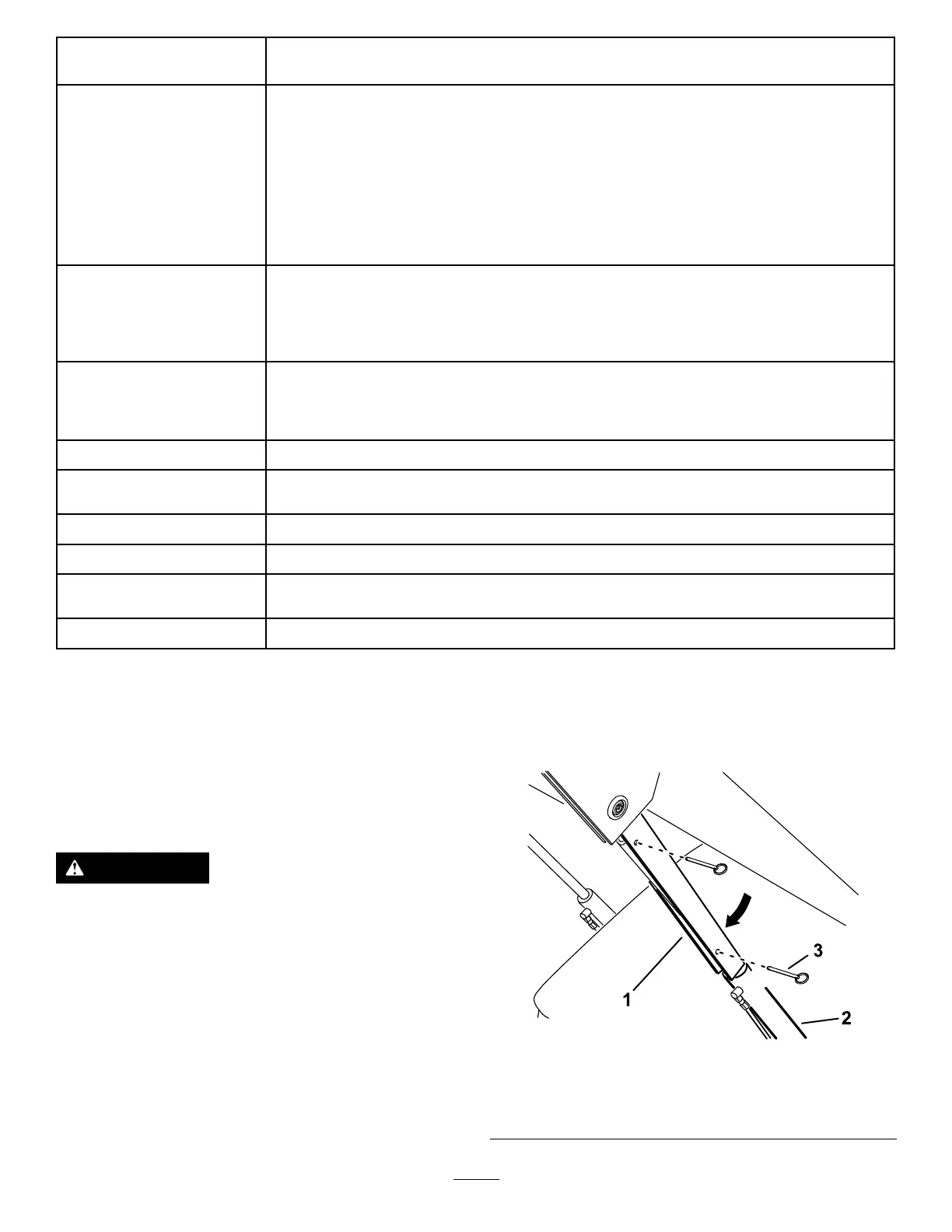

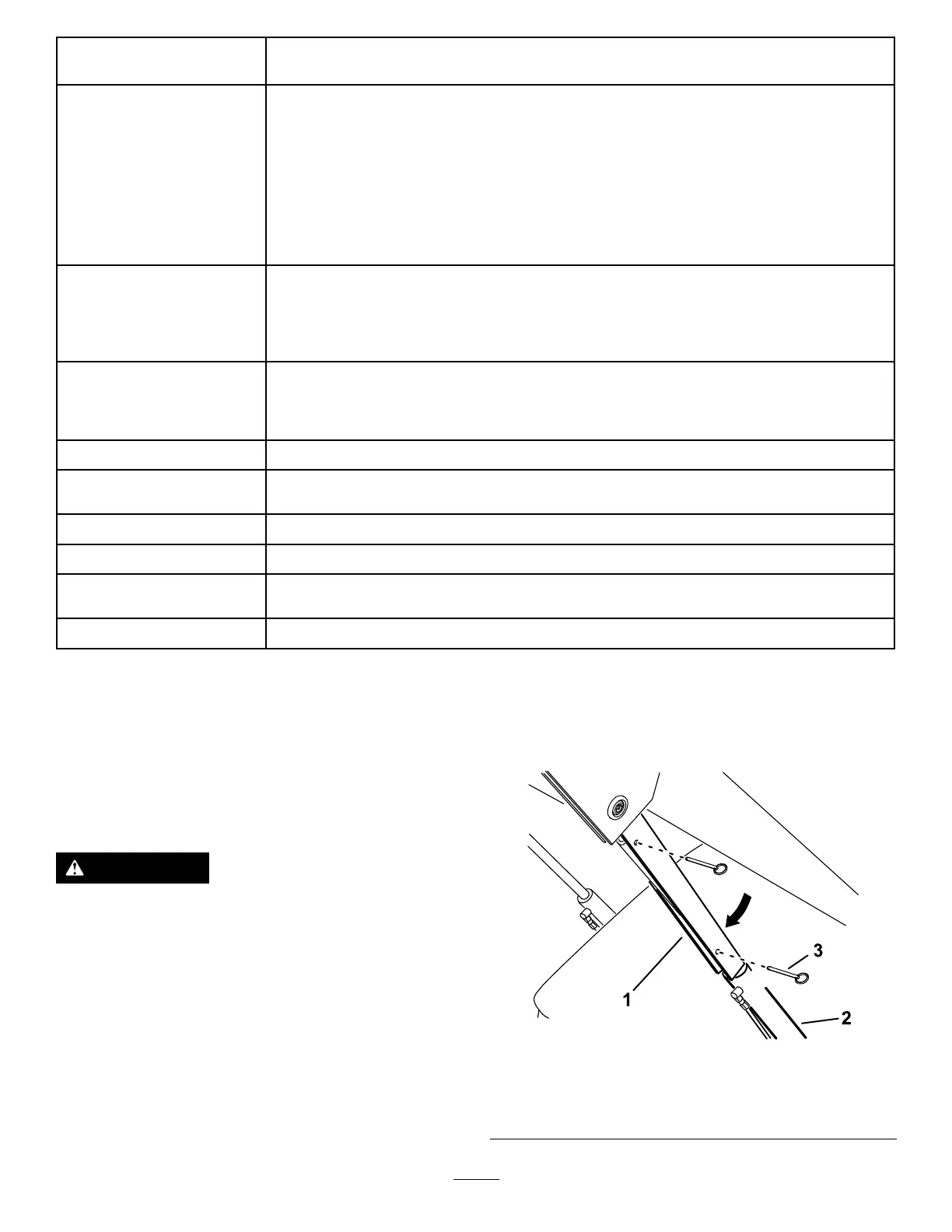

UsingtheCylinderLocks

WARNING

Theloaderarmsmaylowerwhenintheraised

position,crushinganyoneunderthem.

Installthecylinderlock(s)beforeperforming

maintenancethatrequiresraisedloaderarms.

InstallingtheCylinderLocks

1.Removetheattachment.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey.

4.Removethe2pinssecuringthecylinderlockto

thepostsonthesideofthemachine.

5.Slidethecylinderlockoverthelift-cylinderrod

(Figure37).

g267536

Figure37

1.Cylinderlock3.Pin(2)

2.Lift-cylinderrod

29

Loading...

Loading...