2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

Important: Do not substitute automoti v e

oil filter or sev er e h y draulic system dama ge

may r esult.

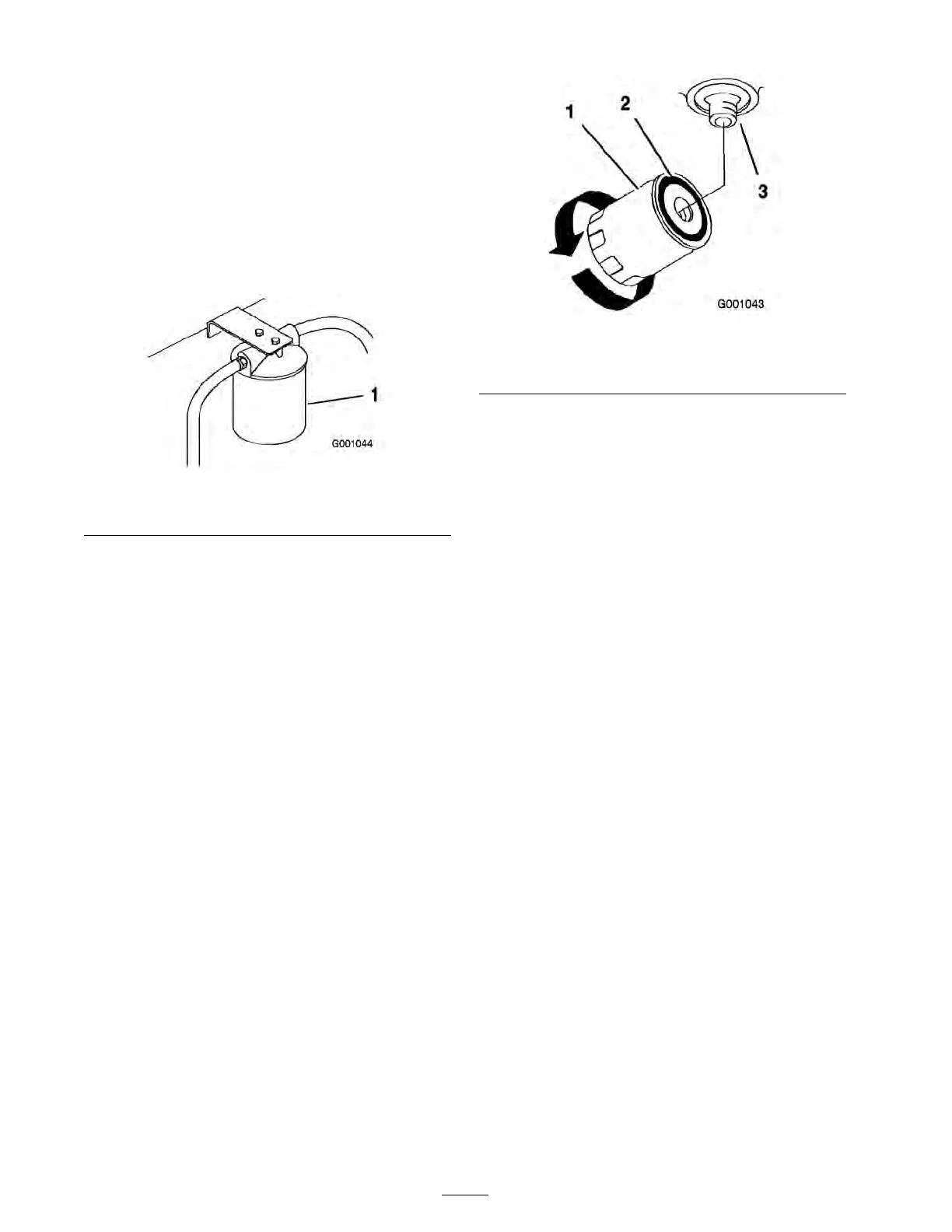

3. Place a drain pan under filter , remo v e the old

filter and wipe the filter adapter g ask et surface

clean ( Figure 56 ).

Figure 56

1. Hydraulic lter

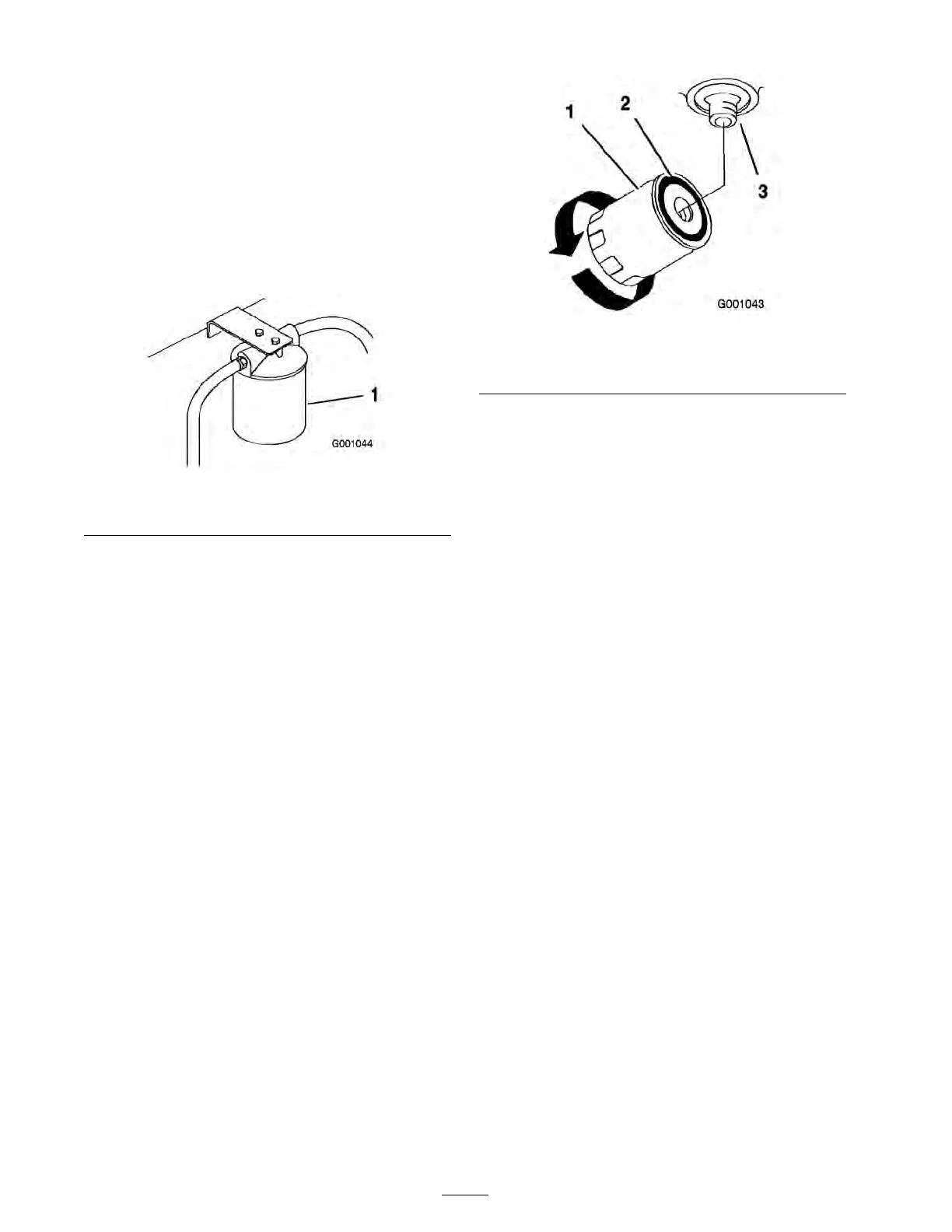

4. Apply a thin coat to the r ubber g ask et on the

re placement filter ( Figure 57 ).

5. Install the re placement h y draulic filter onto the

filter adapter . Do not tighten.

6. Fill the h y draulic tank with h y draulic fluid until

the fluid o v erflo ws the filter and then tur n

the oil filter cloc kwise until the r ubber g ask et

contacts the filter adapter , then tighten the

filter an additional 1/2 tur n ( Figure 57 ).

7. Clean up any spilled fluid.

8. Add fluid to the cold lev el of the baffle in the

h y draulic tank.

9. Star t the engine and let it r un for about tw o

min utes to purg e air from the system. Stop

the engine and c hec k for leaks . If one or

both wheels will not dri v e , refer to Bleeding

Hy draulic System.

10. R ec hec k the fluid lev el while the fluid is w ar m.

T he fluid should be betw een cold and hot.

11. If required, add fluid to the h y draulic tank. Do

not o v erfill.

Figure 57

1. Hydraulic lter 3. Adapter

2. Gasket

Bleeding the Hydraulic System

T he traction system is self bleeding, ho w ev er , it

ma y be necessar y to bleed the system if fluid is

c hang ed or after w ork is perfor med on the system.

1. Raise rear of the mac hine so wheels are off the

g round and suppor t with jac k stands .

2. Star t the engine and r un at lo w idle speed.

Eng ag e the lev er and traction on one side and

spin the wheel b y hand.

3. W hen the wheel begins to spin on its o wn,

k ee p it eng ag ed until wheel dri v es smoothly .

(minim um 2 min utes)

4. Chec k the h y draulic fluid lev el and add as

required to maintain proper lev el.

5. R e peat this procedure on the opposite wheel.

Checking the Hydraulic Hoses

After ev er y 100 operating hours , c hec k the

h y draulic hoses for leaks , loose fittings , kink ed

lines , loose mounting suppor ts , w ear , w eather and

c hemical deterioration. Mak e necessar y re pairs

before operating .

Note: K ee p areas around the h y draulic system

clean from g rass and debris build up .

44

Loading...

Loading...