18

Troubleshooting

6.Disrupted pattern

[Example of phenomenon] [Check item before adjustment]

Is the stitch length dial adjusted the properly?

Is the presser foot pressure appropriate?

Is the feed dog lifted?

Is the stitch width lever positioned correctly?

Step Item Diagnosing Method Standard

Reference

Page

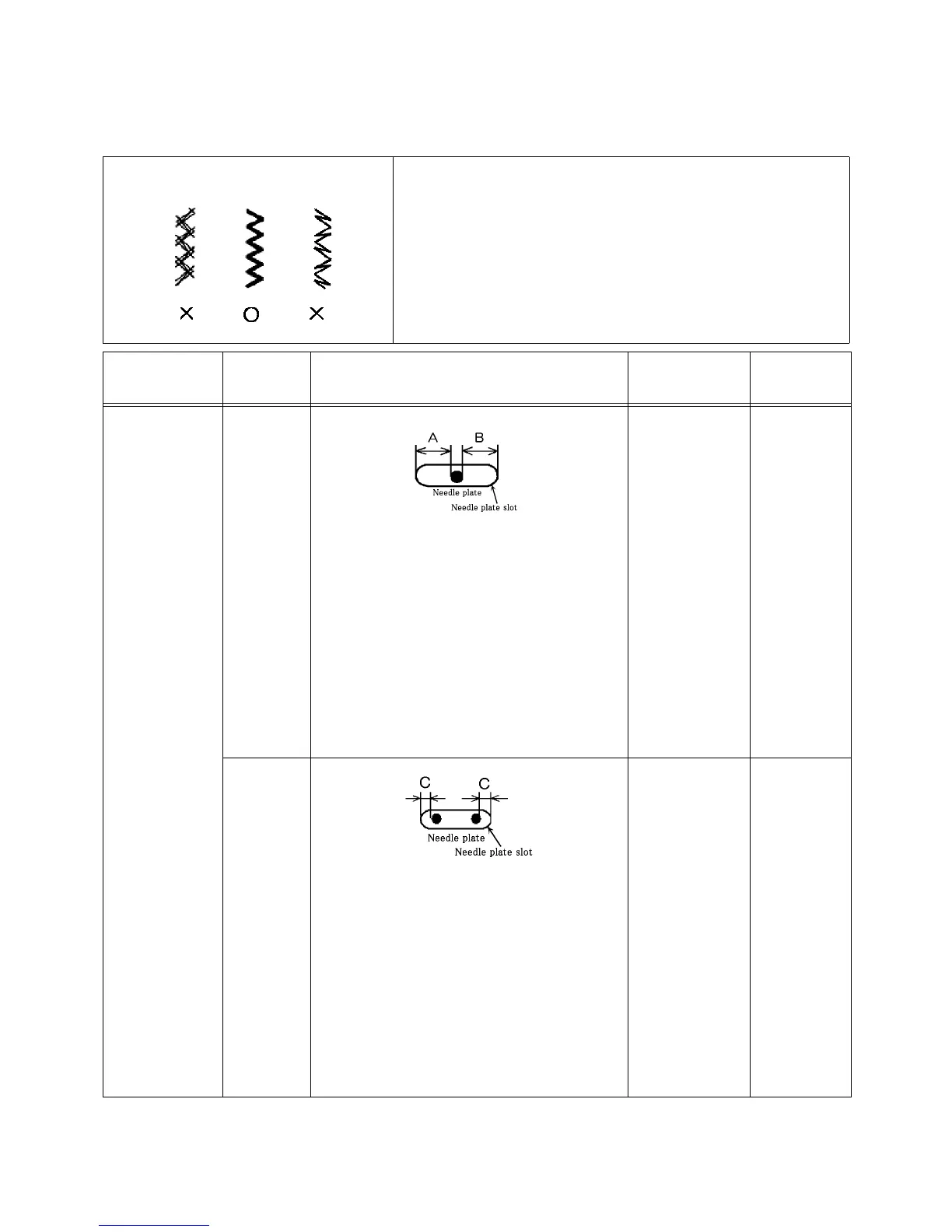

1. Needle and

needle plate

Needle

dropping

points

(At

straight

stitching)

<Condition>

<SD>

Pattern selection dial: "6"

<2D>

Pattern selection dial: "4"

<3D>

Pattern selection dial: "3"

Stitch width lever: "0"

<Diagnosis>

Rotate the handweel, bring down the nee-

dle lower than the surface of needle plate.

Measure the relative position (A, B) be-

tween the needle and the slot.

A = B

[Adjustment]

page.30

Needle

dropping

points

(At

maximum

zigzag

stitching)

<Condition>

<SD>

Pattern selection dial: "11"

<2D>

Pattern selection dial: "7"

<3D>

Pattern selection dial: "3"

Stitch width lever: "5"

<Diagnosis>

Rotate the handweel, bring down the nee-

dle lower than the surface of needle plate.

Measure the relative position (C) between

the needle and the slot.

C = 0.7 ± 0.3

mm

[Adjustment]

page.30

Loading...

Loading...