34

CAUJ-SVX01E-EN

Table 11. Expansion valve selection, 80 to 120 ton MCHE (15% bleed) (continued)

Min Tonnage Max Tonnage

Manufacturer

Selection

(a)

Trane Part

7 12

Sporlan ERZE-8-ZGA (BP/15)

VAL10581

9.5 15.5

Sporlan ERZE-12-1/2-ZGA (BP/15)

VAL10582

12.5 19

Sporlan ERZE-15-ZGA (BP/15)

VAL10583

15 25

Sporlan OZE-20-ZGA (BP/15)

VAL10584

19.5 30

Sporlan OZE-25-ZGA (BP/15)

VAL10585

23.5 45

Sporlan OZE-35-ZGA (BP/15)

VAL10586

35 68

Sporlan OZE-50-ZGA (BP/15)

VAL10587

52.5 70

Sporlan OZE-60-ZGA (BP/15)

VAL10588

(a)

Valve part numbers with “-ZGA” in place of “-GA”, may be used interchangeably.

Ball Shutoff Valves

The ball shutoff valve allows for isolation of the filter/

filter drier for easier core replacement.

Two ball shutoff valves equal to the OD tubing size for

liquid line are required.

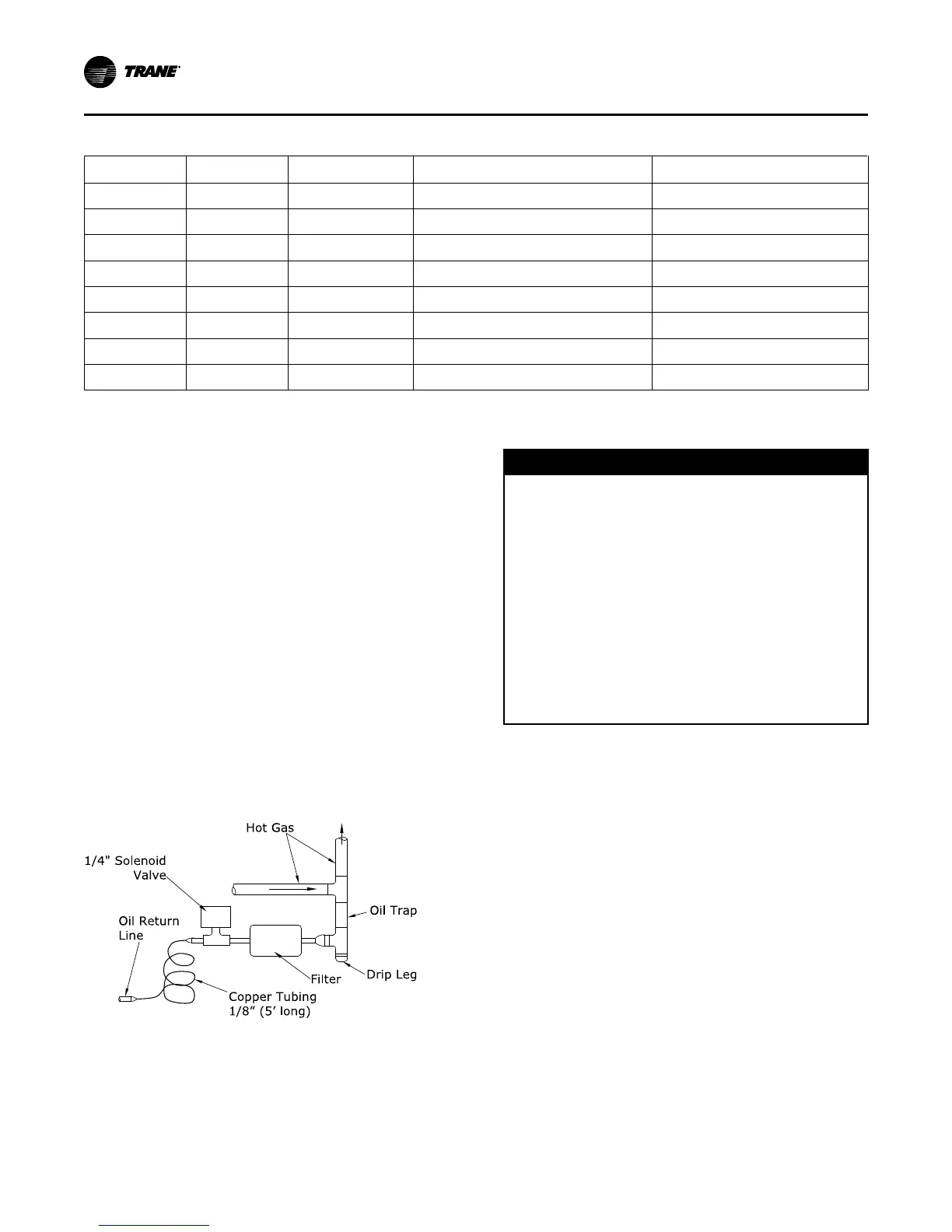

Discharge Line Components

Field supplied hot gas mufflers, pipe anchors, single or

double risers, oil traps, etc. as applicable, should be

provide to prevent excessive line vibration and assure

proper oil return to the compressor for proper system

operation.

A field supplied discharge “shutoff” valve in each hot

gas line near the condenser is recommended to

facilitate refrigerant storage in the condenser during

service procedures.

A“constant drain” oil trap is illustrated below and can

be used as an alternative to a double riser application.

The constant drain oil trap assures adequate oil return

to the suction line even at part load conditions.

Figure 23. Hot gas line components

Oil Tra p

Drip Leg

Hot Gas

1/ 4 " Sole noid

Valve

Filter

Oil Retu rn

Line

Cop per Tubing

1/ 8” (5’ long)

Refrigerant Piping

NNOOTTIICCEE

CCoommpprreessssoorr DDaammaaggee!!

PPOOEE ooiill iiss hhyyggrroossccooppiicc –– iitt aabbssoorrbbss wwaatteerr ddiirreeccttllyy

ffrroomm tthhee aaiirr.. TThhiiss wwaatteerr iiss nneeaarrllyy iimmppoossssiibbllee ttoo

rreemmoovvee ffrroomm tthhee ccoommpprreessssoorr ooiill aanndd ccaann rreessuulltt iinn

ccoommpprreessssoorr ffaaiilluurreess..

TToo pprreevveenntt PPOOEE ooiill ffrroomm aabbssoorrbbiinngg wwaatteerr,, tthhee

ssyysstteemm sshhoouulldd nnoott rreemmaaiinn ooppeenn ffoorr lloonnggeerr tthhaann

nneecceessssaarryy.. WWhheenn ooppeenn,, ddrryy nniittrrooggeenn sshhoouulldd ffllooww

tthhrroouugghh tthhee ppiippiinngg.. OOnnllyy nneeww ooiill ccoonnttaaiinneerrss

sshhoouulldd bbee uusseedd ffoorr sseerrvviiccee aanndd mmaaiinntteennaannccee..

AAllwwaayyss uussee tthhee ssmmaalllleesstt ccoonnttaaiinneerr ssiizzee rreeqquuiirreedd

ffoorr tthhee jjoobb rreeqquuiirreemmeennttss.. AAllwwaayyss lleeaavvee tthhee ooiill

ccoonnttaaiinneerr ttiigghhttllyy sseeaalleedd uunnttiill ttiimmee ooff uussee.. DDoo nnoott

rreeuussee ooiill tthhaatt hhaass bbeeeenn ooppeenneedd..

Refrigerant piping must be properly sized and applied.

These two factors have a very significant effect on both

system performance and reliability.

NNoottee:: Use Type “L” refrigerant grade copper tubing

only.

Refrigerant Piping should be sized and laid out

according to the job plans and specifications. This

should be done when the system components are

selected.

The primary objective when sizing refrigerant piping

for this unit is to make refrigerant line sizes as small as

possible while avoiding excessive refrigerant pressure

drops.

Sizing refrigerant lines as small as possible minimizes

the required refrigerant charge and maximizes

compressor life.

See SS-APG012-EN for line sizing information.

Liquid Line Piping

Basic sizing parameters with the system operating at

full load for liquid lines are:

• Maximum Liquid velocity: 600 fpm

IInnssttaallllaattiioonn MMeecchhaanniiccaall

Loading...

Loading...