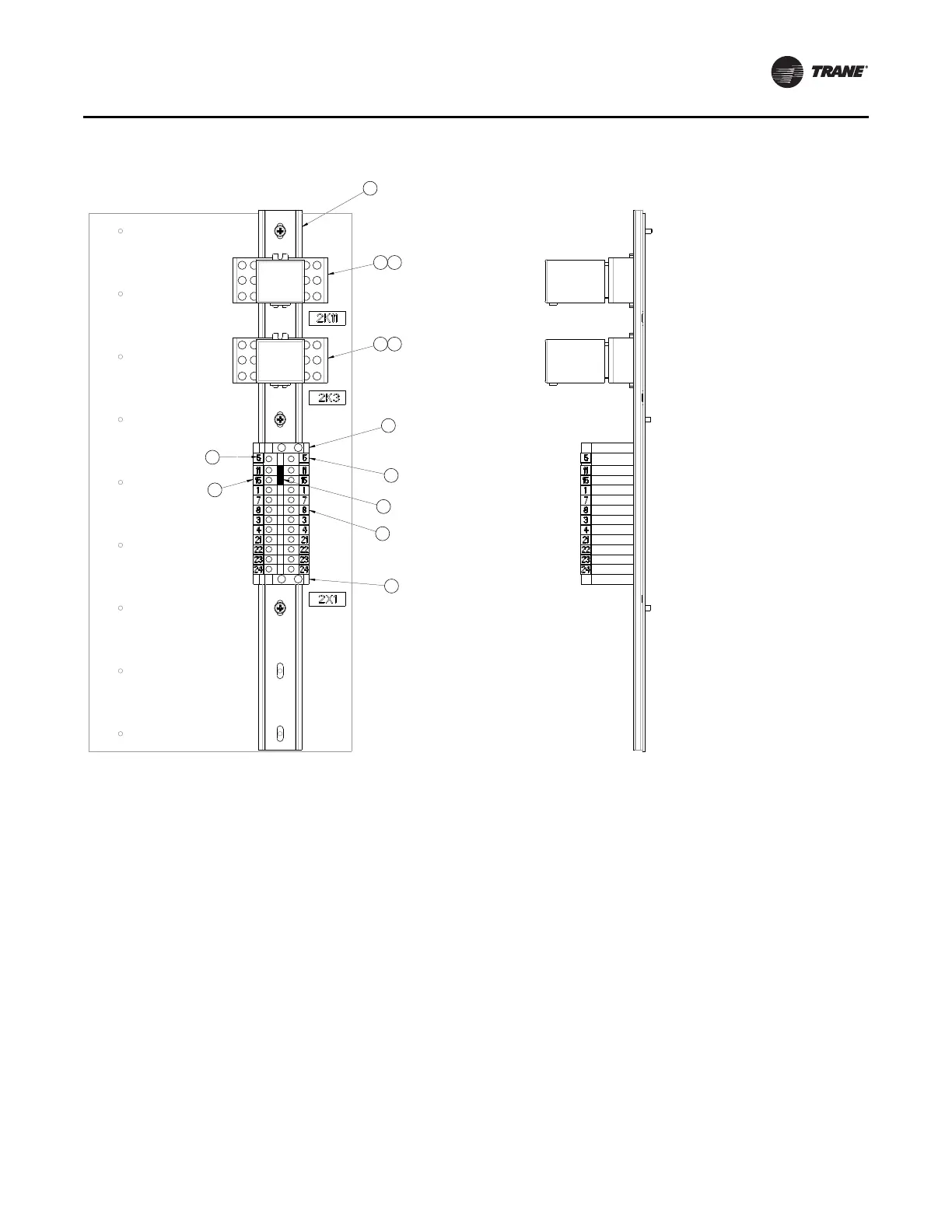

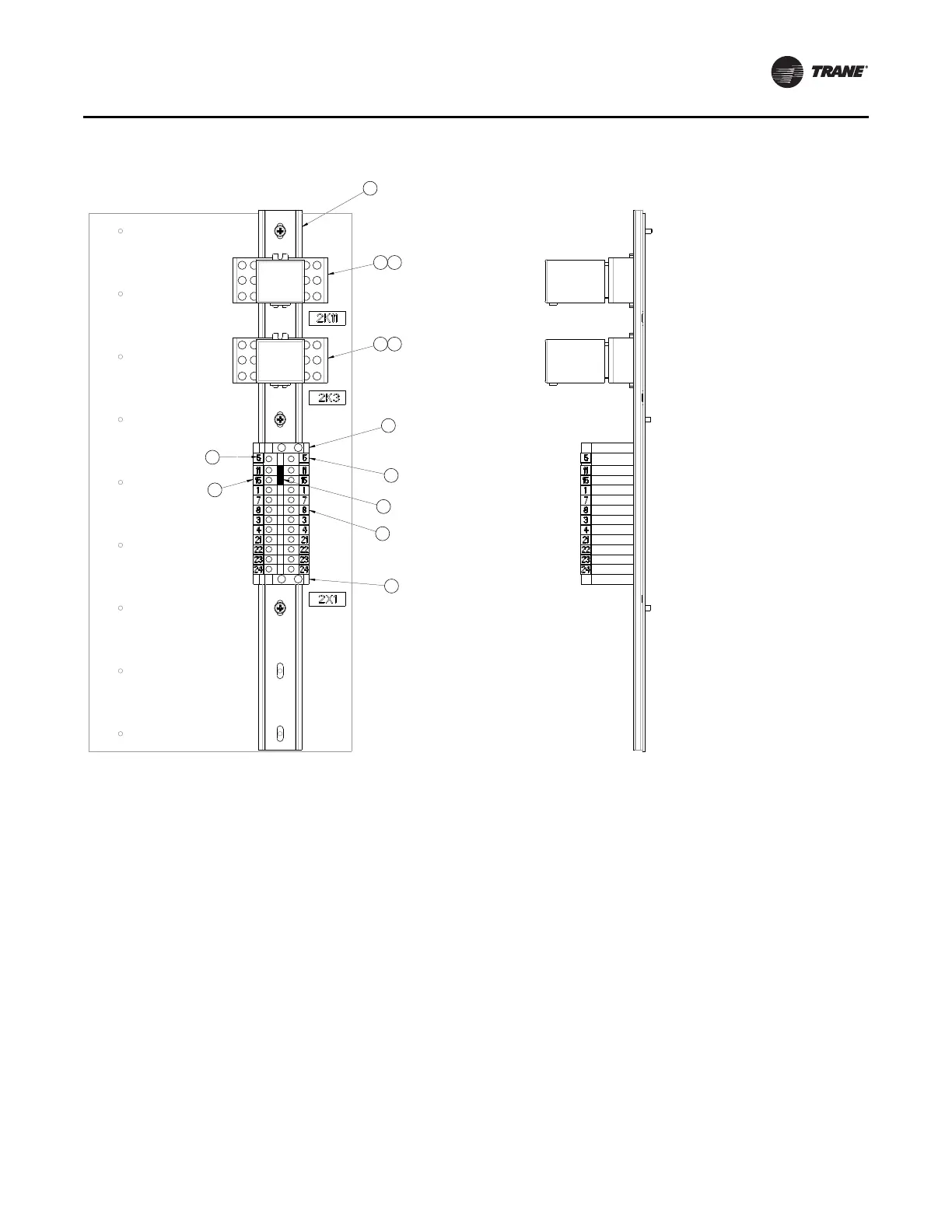

Figure 20. Expanded view of terminal block

(a)

1

2

3

4

5

6

A

B

7

8

9

1

2

3

4

5

6

A

B

7

8

9

1

23

23

4

4

5

9

6

7

8

1. Din Rail

2. Relay Socket

3. Relay

4. End Barrier

5. Ground Terminal Block

6. Terminal Block

7. Tab

8. Tab

9. Jumper

Input Power and Control Wiring

AFDK-SVU01C-EN 39

Communications wires should be terminated at the

communication card (recomm) provided on the drive. The

location of the communication card is called out as item 18

on Figure 3, p

. 12 for Frame 3 units and item 16 on

Figure 6, p. 16 for Frame 4 units. Field-installed

communica

tions wiring should be routed so that it is

segregated from all other wiring.

Refer to specific chiller documentation for exact control

panel conn

ection locations.

In remote-mount applications, the AFDK must also be

wire

d to contro

l the drive-cooling assembly. 2X1-23 and

2X1-24 provide a normally open contact. When drive

cooling is required, the contact will close and begin the

cooling system operation.

The accurate pressure readings required by the chiller

con

trols to ena

ble the most efficient operation of the

chiller with the retrofitted AFDK drive can only be

effectively measured with a pressure transducer.

A condenser pressure transducer and associated

com

mun

ications cables are included in the Valve and

Hardware kit for AFDK (020600790100). Mount the device

and connect to the IPC bus. With a laptop connected to the

chiller and with Tracer™ TU or TechView™ running, enter

the binding view menu. Highlight the device name, press

bind button, and then select the physical device with a

south pole magnet.

(a)Material courtesy of Rockwell.

Loading...

Loading...