Transporting The Chipper/Shredder

When

you

move

your

equipment, please

follow

the

instructions below. Remember - the JUNIOR

TOMA-

HAWK® Chipper/Shredder weighs over

100

pounds.

This weight must be properly balanced over the wheel

axle and carefully rolled in

order

to

move the

equip-

ment safely and easily. Here's how:

• First

shuttheengine

OFF. Allow the engine and mov-

ing blades

to

come

to

a complete stop before proceed-

ing. Then disconnect the spark plug wire.

• Place both hands evenly and

firmly

on the handle. A

good

grip

is important.

• Place one

foot

on the wheel axle, halfway between

the ends

of

the axle. Your other foot should

be

firmly

planted.

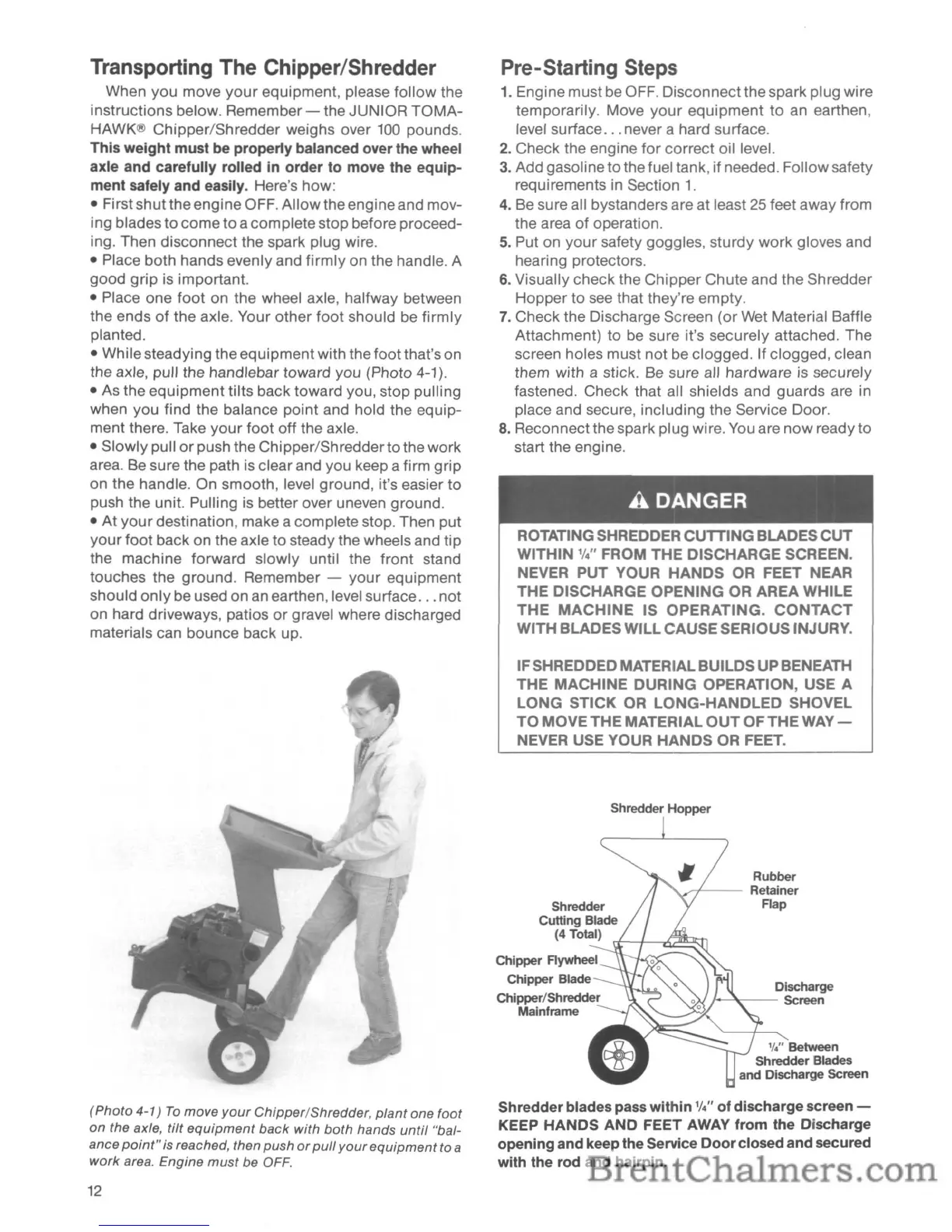

• While steadying the equipment with the foot that's on

the axle, pull the handlebar toward you (Photo 4-1).

• As the

equipment

tilts back toward you, stop pulling

when you find the balance point and hold the equip-

ment there. Take

your

foot off the axle.

• Slowly pull

or

push the

Chipper/Shreddertothe

work

area. Be sure the path is clear and you keep a firm grip

on the handle. On smooth, level ground, it's easier

to

push the unit. PUlling is better over uneven ground.

•

At your

destination, make a complete stop. Then put

your

foot

back on the axle to steady the wheels and tip

the machine forward slowly until the front stand

touches the ground. Remember -

your

equipment

should

only

be used on an earthen, level surface

...

not

on hard driveways, patios

or

gravel where discharged

materials can bounce back up.

Pre-Starting Steps

1.

Engine must be OFF. Disconnect the spark plug wire

temporarily. Move

your

equipment

to

an earthen,

level surface

...

never a hard surface.

2.

Check the engine

for

correct oil level.

3.

Add gasoline

to

the fuel tank, ifneeded. Follow safety

requirements in Section

1.

4.

Be

sure all bystanders are at least

25

feet away from

the area

of

operation.

5.

Put on

your

safety goggles, sturdy work gloves and

hearing protectors.

6.

Visually check the Chipper Chute and the Shredder

Hopper to see that they're empty.

7.

Check the Discharge Screen (or Wet Material Baffle

Attachment) to be sure it's securely attached. The

screen holes must not be clogged. If clogged, clean

them with a stiCk. Be sure all hardware is securely

fastened. Check that all shields and guards are in

place and secure, including the Service Door.

8.

Reconnect the spark plug wire.

You

are

now

ready

to

start the engine.

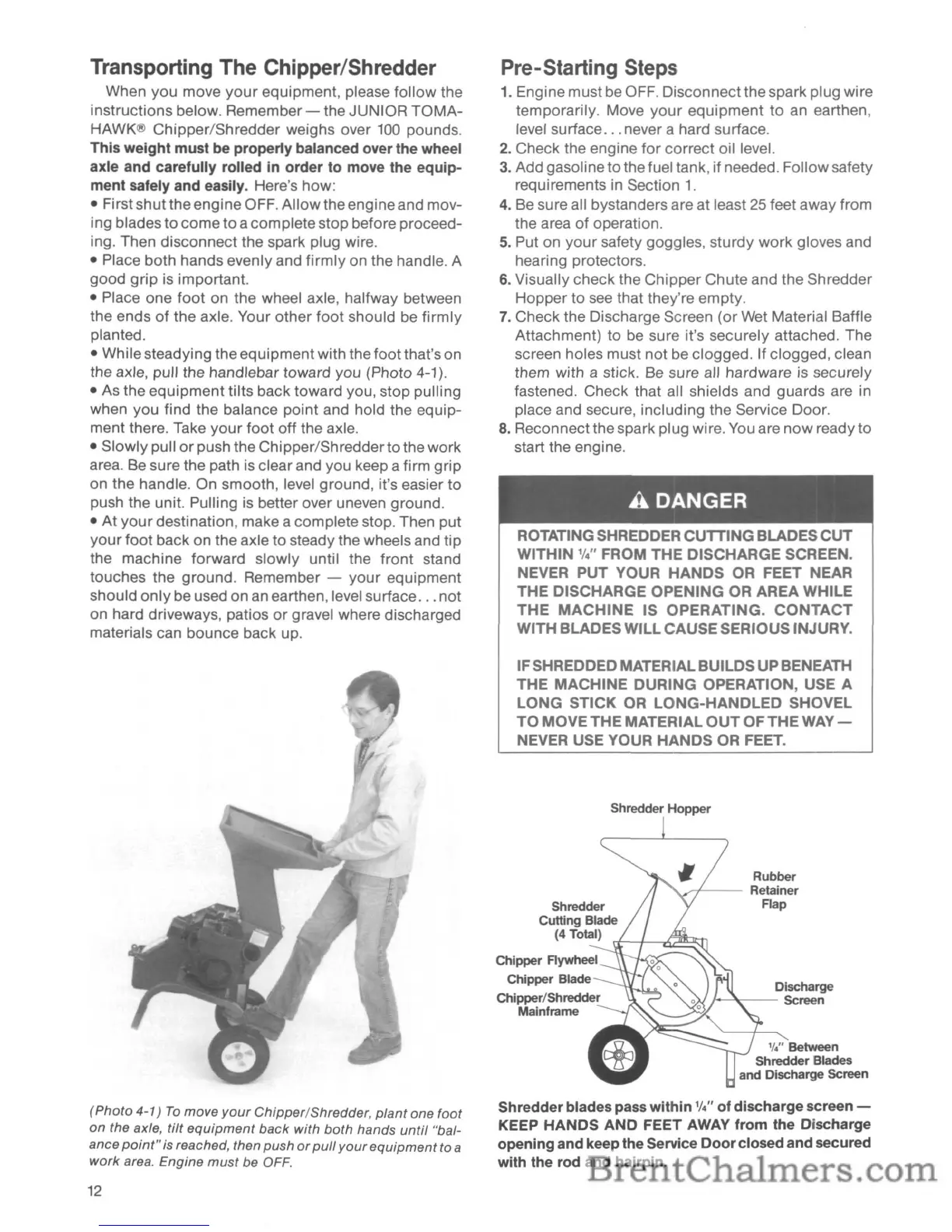

A DANGER

ROTATING SHREDDER CUTTING BLADES

CUT

WITHIN

114"

FROM THE DISCHARGE SCREEN.

NEVER PUT YOUR

HANDS

OR FEET NEAR

THE DISCHARGE OPENING OR AREA WHILE

THE

MACHINE

IS

OPERATING.

CONTACT

WITH BLADES WILL CAUSE SERIOUS INJURY.

Shredder Hopper

IFSHREDDED MATERIAL BUILDSUPBENEATH

THE

MACHINE

DURING OPERATION, USE A

LONG

STICK

OR

LONG-HANDLED

SHOVEL

TO

MOVE THE MATERIAL

OUT

OF

THE

WAY

-

NEVER USE YOUR

HANDS

OR FEET.

'I'" Between

Shredder Blades

and Discharge Screen

Discharge

J--T---

Screen

Rubber

..r+--

Retainer

Flap

Chipper Flywheel

Chipper Blade

Chipper/Shredder

Mainframe

(Photo

4-1)

To

move

your

Chipper/Shredder,

plant

one foot

on

the axle,

tilt

equipment

back

with

both

hands

until

"bal-

ance

point"

is reached, then push

or

pull

your

equipment

to a

work

area. Engine

must

be

OFF.

Shredderblades pass

within

1f4"

of

discharge screen -

KEEP

HANDS

AND FEET AWAY from the Discharge

opening and keep the Service

Door

closed and secured

with the rod and hairpin.

12

Loading...

Loading...