Operating the Classifier 5–7

Impactor

The primary function of the impactor is to remove larger particles

that carry more than a single charge. However, the impactor is also

used as a flowmeter, since the pressure drop across the impactor is

proportional to the square of the flow rate.

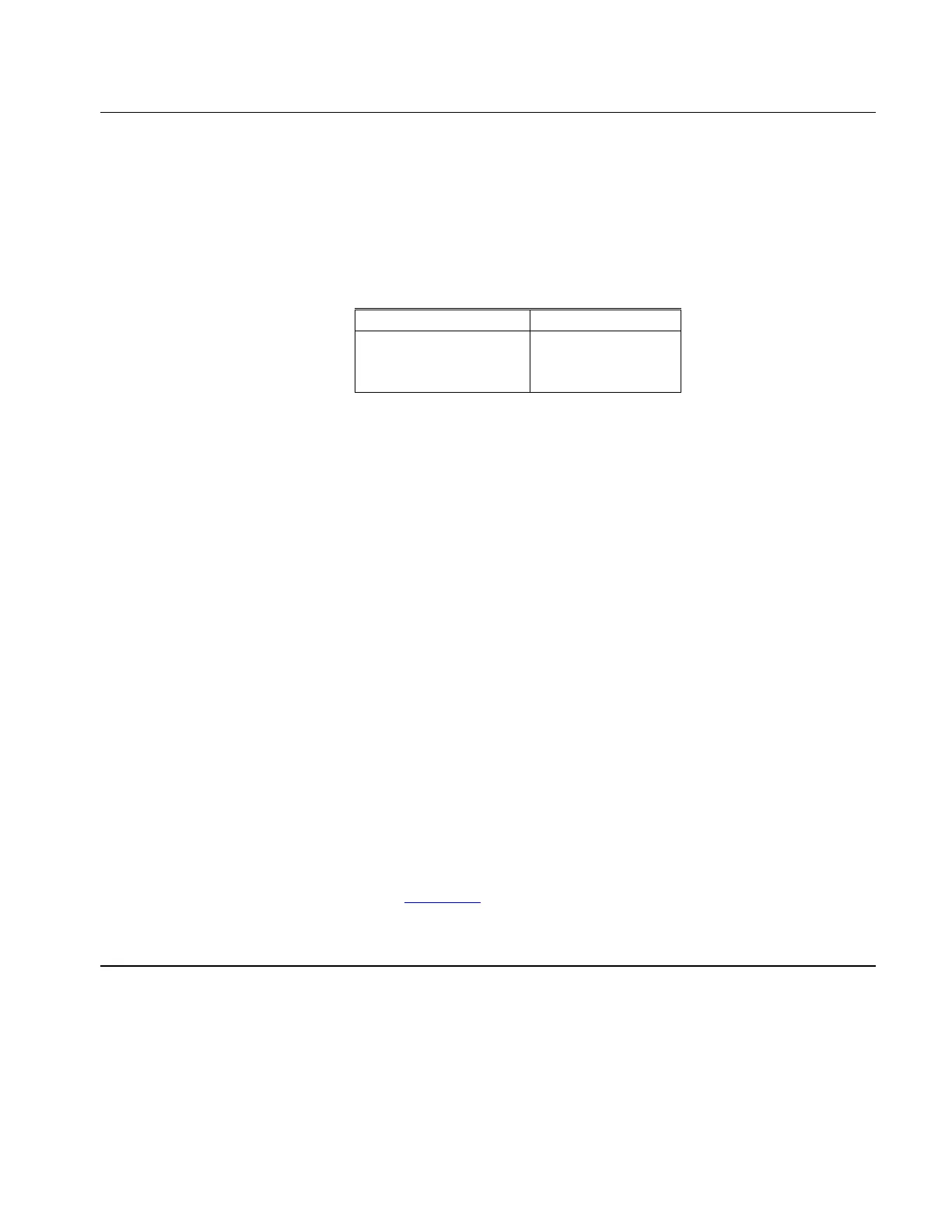

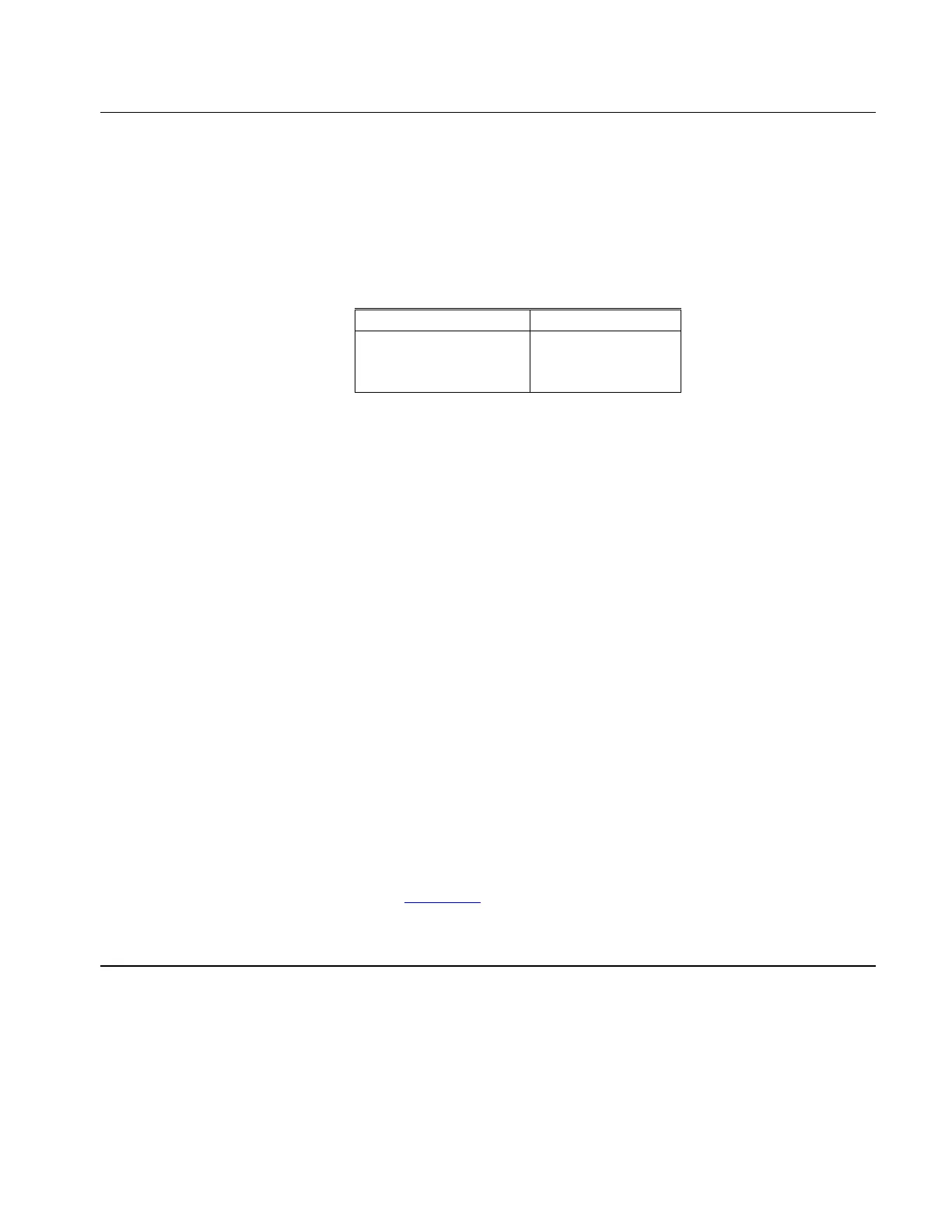

Table 5-3

Flow Range for Each Impactor Nozzle

Flow Range (L/min) Nozzle Size (cm)

0.2 to 0.8 0.0457

0.3 to 1.0 0.0508

0.6 to 2.1 0.071

The nozzle size and flow rate determine the largest particle size that

can be sampled within each SMPS measuring size range. For best

results, use Table 5-3 to determine the correct nozzle to use for the

flow you set. Each nozzle is interchangeable and can be screwed

into the impactor body with a gasket to seal the thread. Using the

Multifunction pane in the display, you can view the sample flow

rate directly from the pressure drop measured across the impactor.

The Classifier stores an internal calibration curve for each impactor

size and serial number. To change the impactor, follow the steps

below:

1. Turn on the Classifier and rotate the control knob to highlight

the Menu pane on the display.

2. Click the control knob by pushing in. This should bring up the

menu.

3. Scroll by rotating the control knob until Impactor is highlighted

and then click the selection.

4. Select the impactor size and serial number corresponding to the

impactor physically installed and click the selection.

5. Scroll the menu up or down to Exit and click.

When you have selected a nozzle size you need to physically install

it (see Chapter 2

).

Sheath Air Flow Controller

Traditionally, most DMAs have been set up with four flows:

polydisperse, sheath, excess, and monodisperse. Managing all of

these flows can be a daunting task requiring several vacuum or

pressure sources and complex plumbing. Although the Model 3080

Loading...

Loading...