2PS/2PT

1-4-32

(6) The background is colored.

(7) White streaks are printed vertically.

(8) Black streaks are printed vertically.

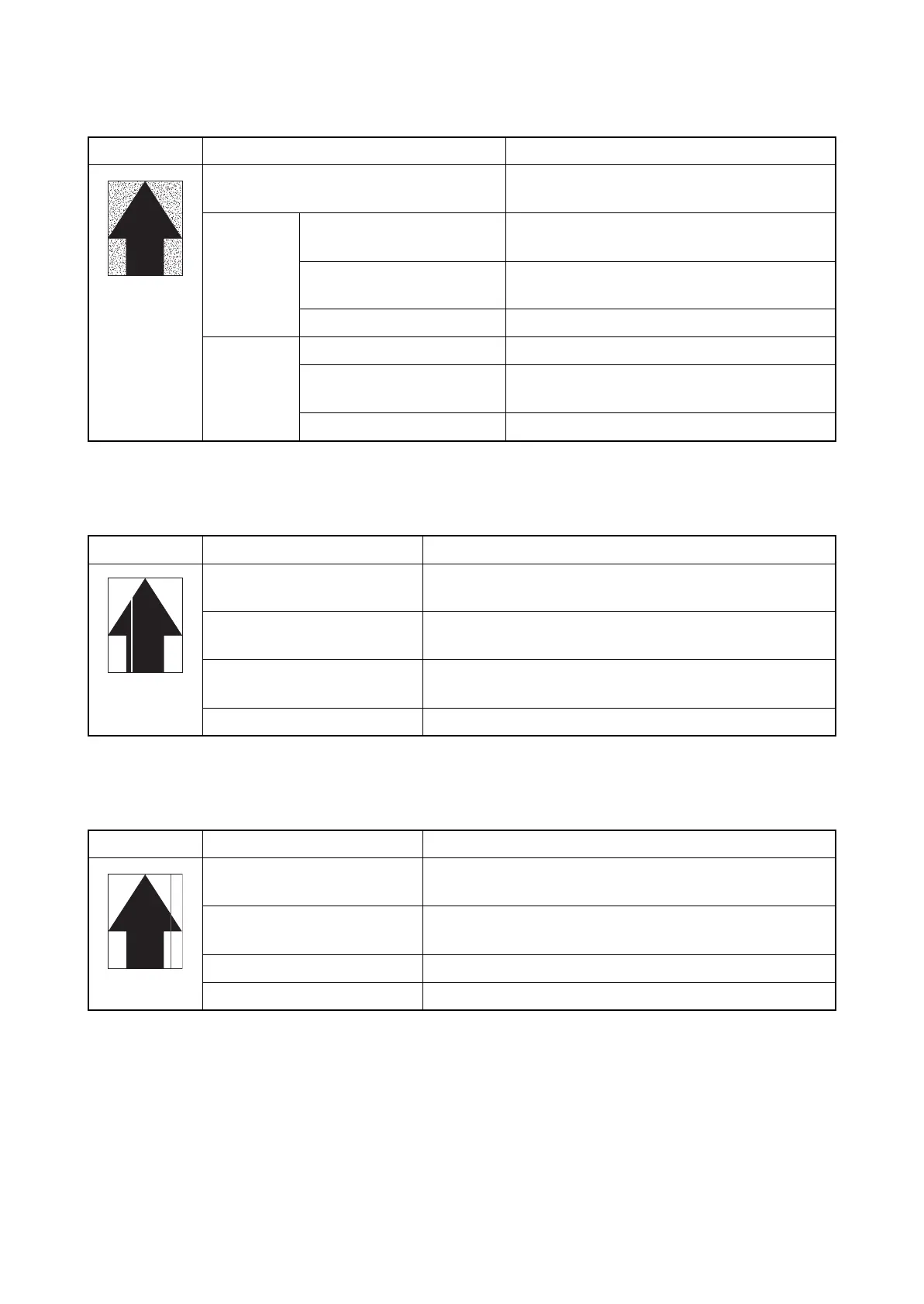

Print example Causes Check procedures/corrective measures

Defective color calibration. Perform the color calibration (Refer to opera-

tion guide).

Defective

developing

bias output.

Defective developing unit. Replace the developing unit for the color that

causes an error (see page 1-5-18).

Defective high voltage

PWB.

Replace the high voltage PWB

(see page 1-5-34).

Defective engine PWB. Replace the engine PWB (see page 1-5-26).

Defective

drum sur-

face charg-

ing.

Defective drum unit. Replace the drum unit (see page 1-5-20).

Defective high voltage

PWB.

Replace the high voltage PWB

(see page 1-5-34).

Defective engine PWB. Replace the engine PWB (see page 1-5-26).

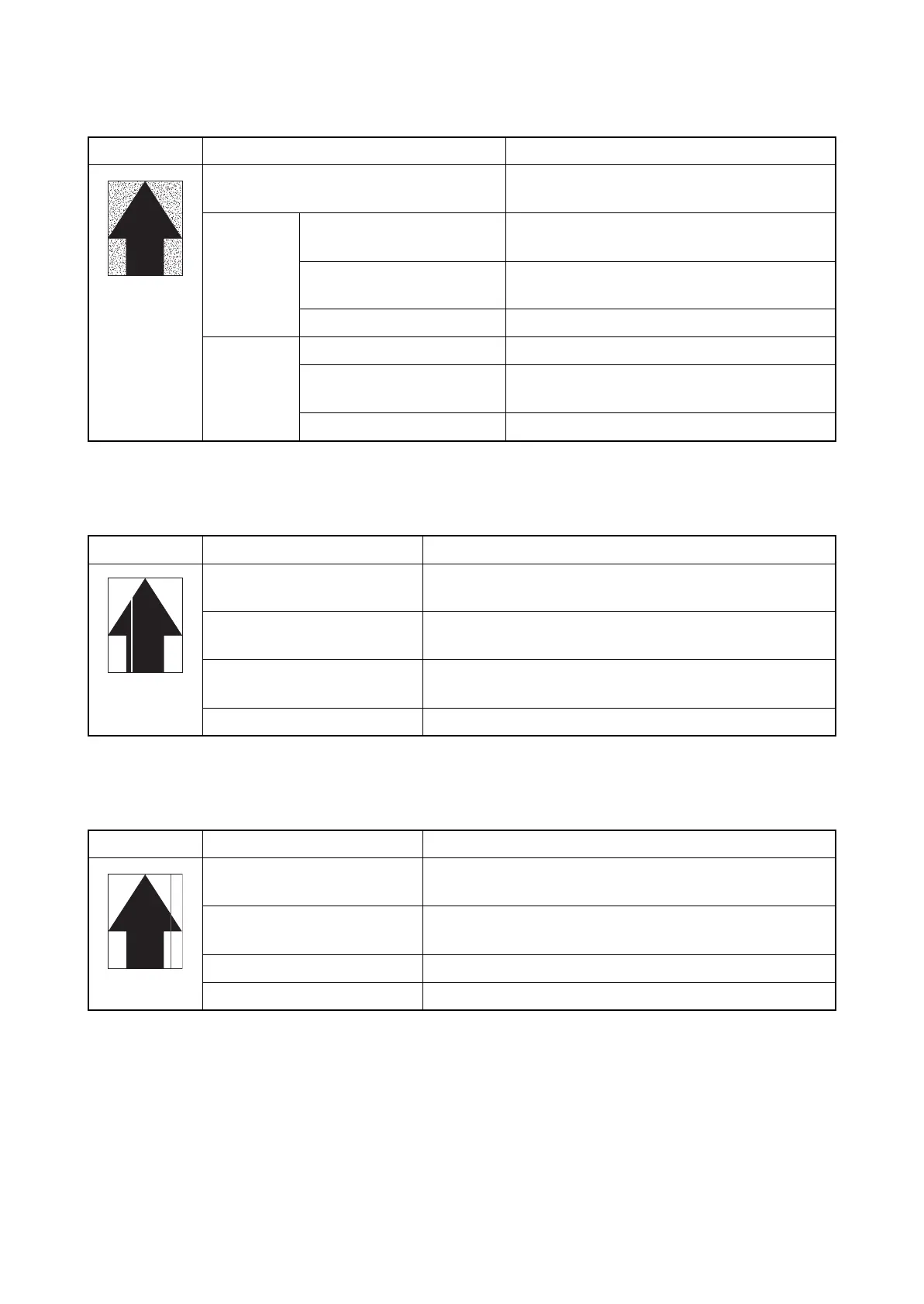

Print example Causes Check procedures/corrective measures

Foreign object in one of the

developing units.

Replace the developing unit for the color that causes an

error (see page 1-5-18).

Adhesion of soiling to transfer

belt.

Clean the transfer belt. Replace the intermediate transfer

unit if it is extremely dirty (see page 1-5-21).

Adhesion of soiling to transfer

roller.

Clean the transfer roller. Replace the transfer roller if it is

extremely dirty (see page 1-5-24).

Dirty LSU dust shield glass. Perform the LSU dust shield glass cleaning.

Print example Causes Check procedures/corrective measures

Dirty or flawed drum. Perform the drum surface refreshing (see page 1-3-13).

Flawed drum. Replace the drum unit (see page 1-5-20).

Deformed or worn cleaning

blade in the drum unit.

Replace the drum unit (see page 1-5-20).

Worn primary transfer belt. Replace the intermediate transfer unit (see page 1-5-21).

Defective transfer roller. Replace the transfer roller (see page 1-5-24).

Loading...

Loading...