1 1/8 350 470 775 1025 1200 1600

1 1/4 500 660 1100 1470 1800 2400

1 1/2 880 1180 1900 2500 3000 4000

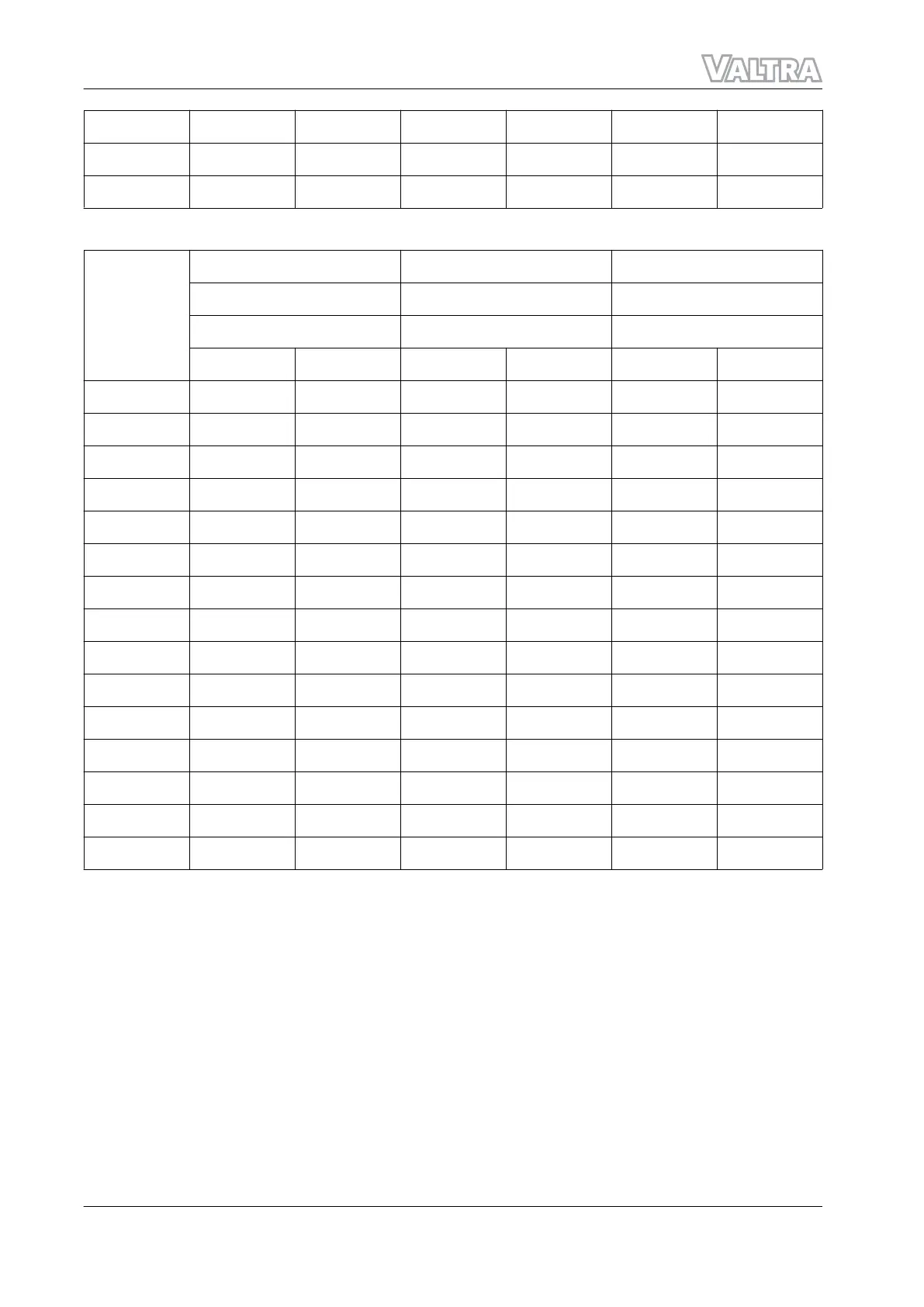

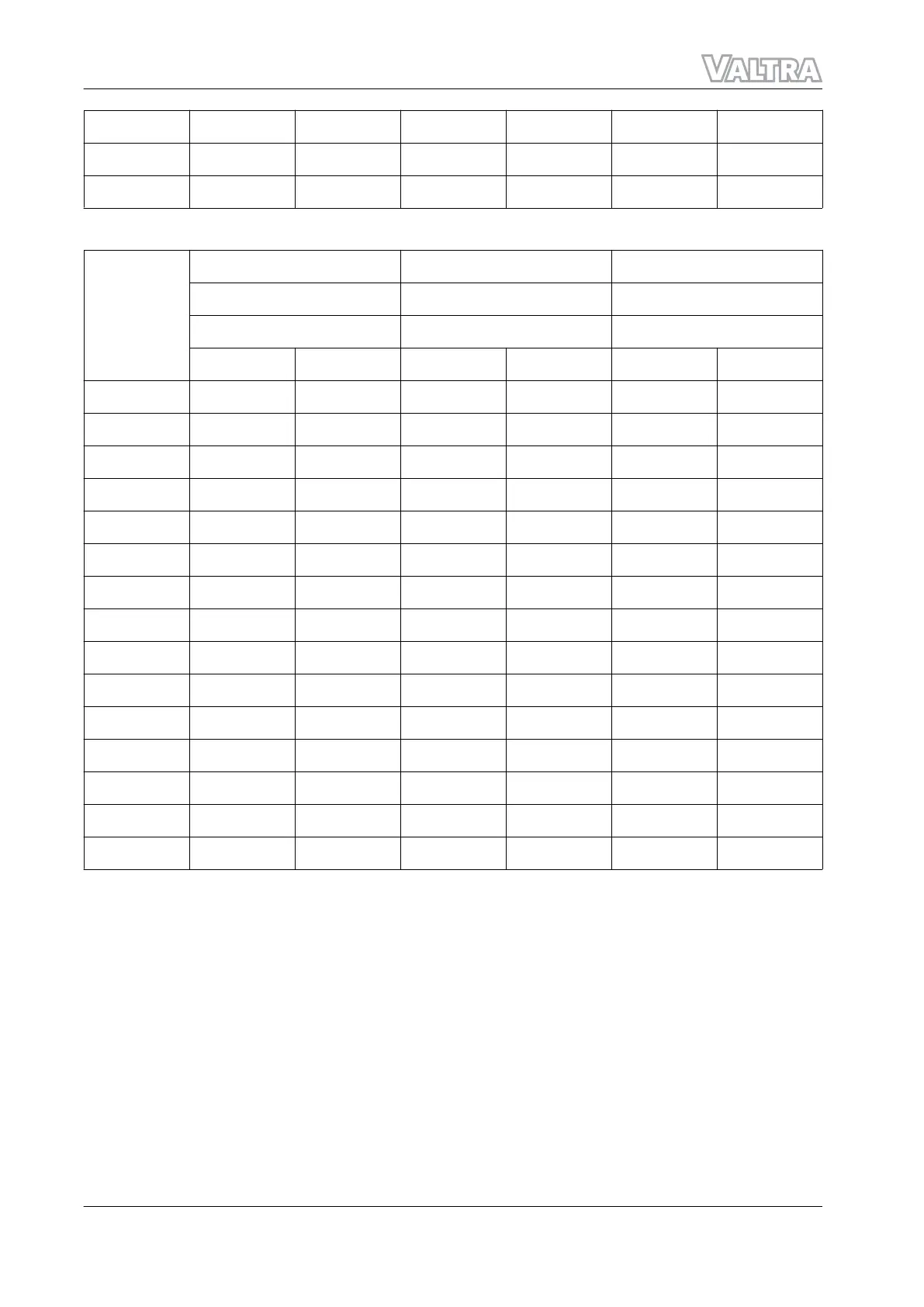

6 - Reduced tightening torque values: phosphated or zinc-flake-coated threads in inches

Nominal

dimension

Tensile grade Tensile grade Tensile grade

SAE 1 (ISO 10.9-BS B) SAE 5 (ISO 8.8-BS S) SAE 8 (ISO 10.9-BS V)

Torque lbf ft Torque lbf ft Torque lbf ft

Min. Max. Min. Max. Min. Max.

#6 0.5 0.8 1 1.4 1.5 1.9

#8 1 1.4 2 2.6 2.7 3.7

#10 1.5 1.9 2.7 3.7 3.9 5.3

1/4 3.5 4.7 6.6 8.8 9 13

5/16 7 9.4 13 18 18 25

3/8 13 18 23 31 32 (44)

7/16 20 28 37 51 53 71

1/2 32 42 59 77 82 106

5/8 65 83 120 150 160 220

3/4 110 150 210 270 290 390

7/8 180 240 330 450 470 630

1 270 370 500 660 710 940

1 1/8 280 380 620 820 1000 1300

1 1/4 400 530 880 1180 1400 1900

1 1/2 700 940 1500 2000 2400 3200

1.1.4.2 Tightening torques for hydraulic unions

Use the tightening torques recommended for hydraulic unions according to the tables below:

• 1 for hydraulic unions with 37° flare

• 2 for EO2 hydraulic unions

• 3 for hydraulic unions with metric straight thread

• 4 for hydraulic unions with straight thread in inches

• 5 for steel unions with sealed thread.

When a specific torque is required, this is stated in the text.

The specifications for these tightening torques apply to zinc-plated steel unions used with hoses and rigid

hydraulic pipes that ideally include straight thread unions, unions with 37° flare or unions with an "O" ring

for bosses.

These values apply to dry assemblies. If the threads are oiled, reduce the tightening torques.

GUID-C9372A73-1E9A-44D6-A823-3E213BCDC08C [V1]

1. Introduction

1-20

ACX2831410

Loading...

Loading...