5 PIPING REQUIREMENTS

All fluid connections to the unit, with the exception of the condensate drain, are sweat copper. Factory-

installed piping brackets must not be removed. Field-installed piping must be installed in accordance with

local codes and must be properly assembled, supported, isolated and insulated. Avoid piping runs

through noise-sensitive areas, such as office walls and conference rooms.

Refer to specific text and detailed diagrams in this manual for other unit-specific piping requirements.

All piping below the elevated floor must be located so that it offers the least resistance to air flow. Careful

planning of the piping layout under the raised floor is required to prevent the air flow from being blocked.

When installing piping on the subfloor, we recommend that the pipes be mounted in a horizontal plane

rather than stacked one above the other. Whenever possible, the pipes should be run parallel to the air

flow.

The pipe connection locations, piping general arrangement and schematics are described in the

submittal documents included in the Submittal Drawings on page45.

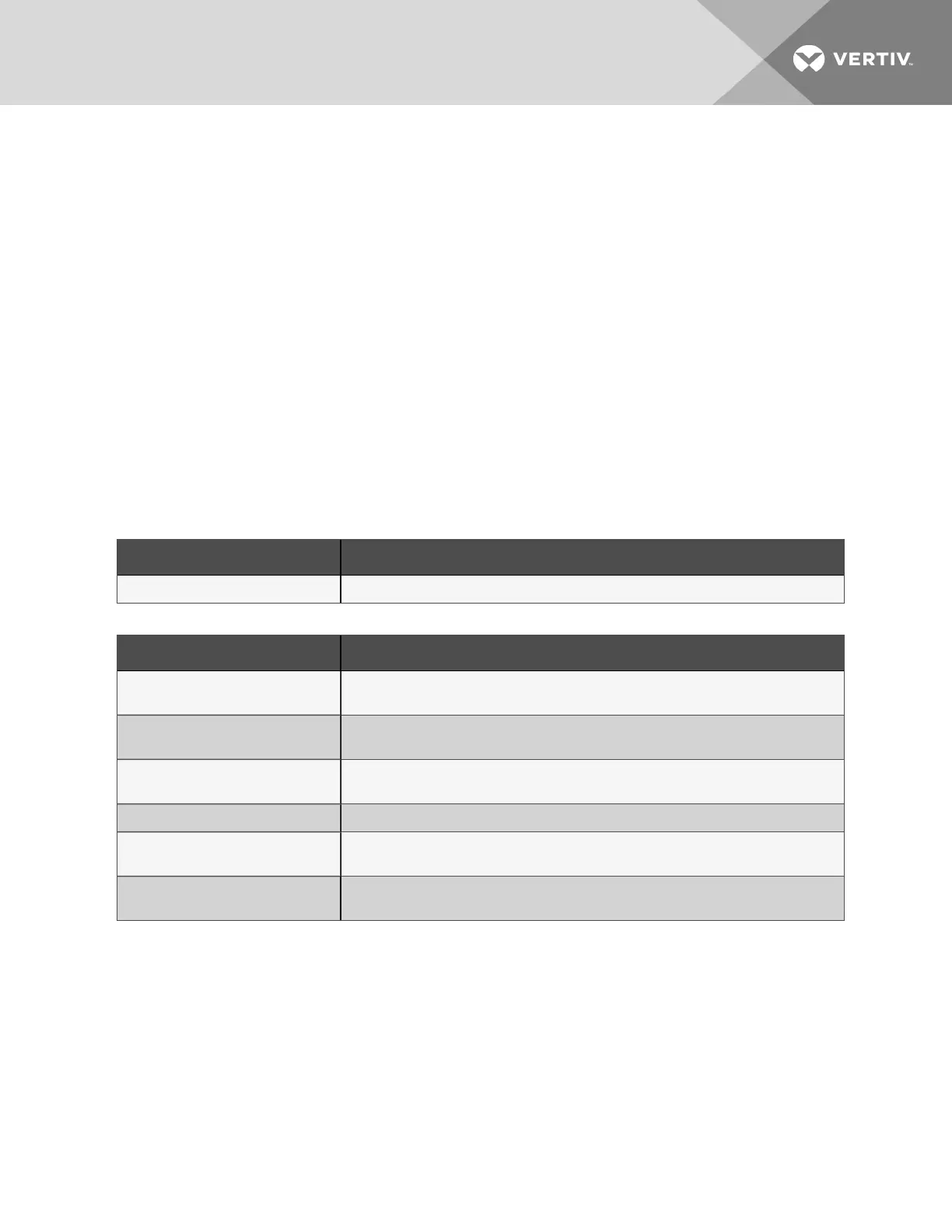

The following tables list the relevant documents by number and title.

Document Number Title

DPN004952 Piping Schematic, Downflow, CW305, 375, 415

Table 5.1 Piping General-arrangment Drawings

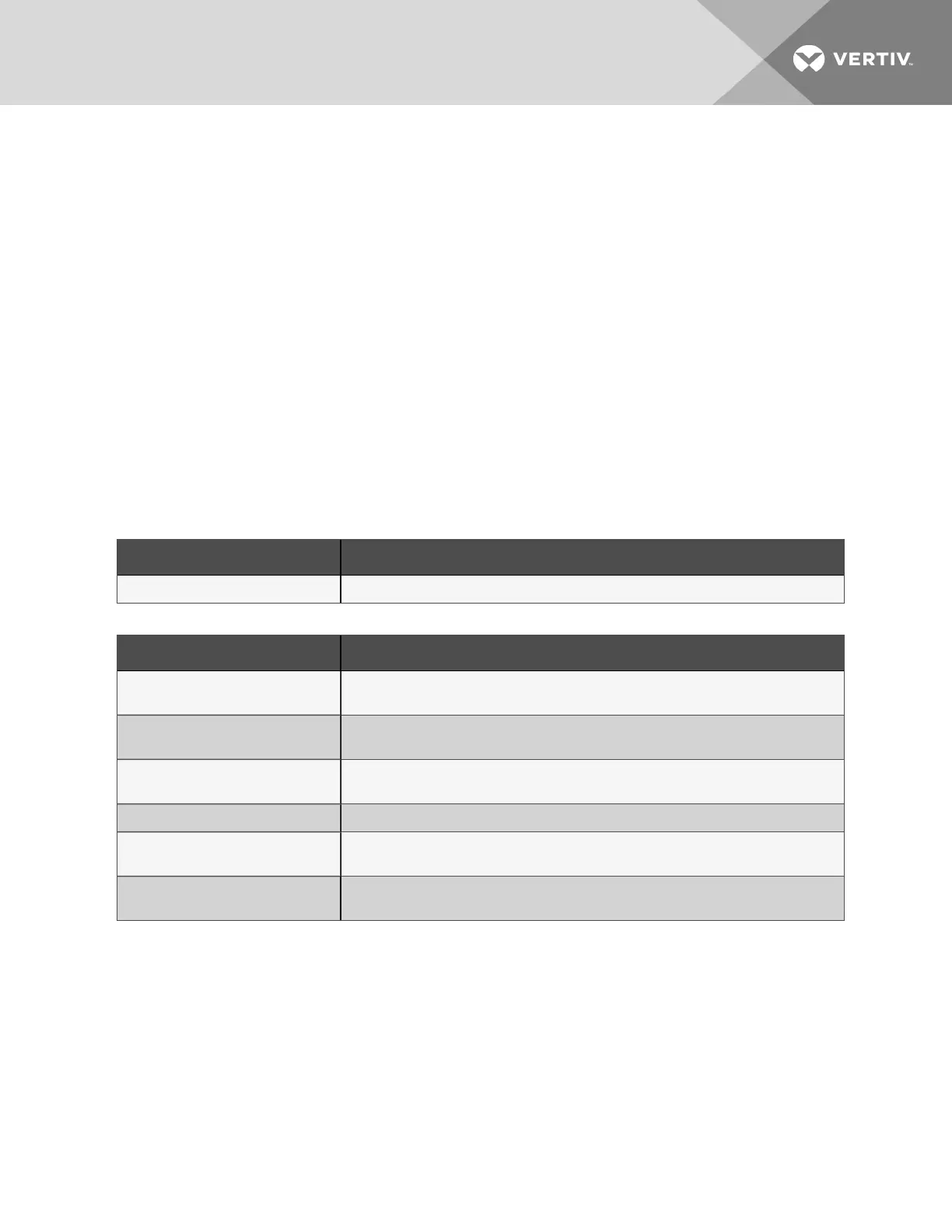

Document Number Title

DPN004863

Connection Locations, Data Hall with horizontal-discharge, Front-left facing

electrical/piping compartment

DPN004901

Connection Locations, Bottom-discharge, Front-right facing electrical/piping

compartment

DPN004923

Connection Locations, Data Hall with horizontal-discharge, Front-right facing

electrical/piping compartment

DPN004903 Connection Locations, Bottom-discharge, Front-left facing electrical/piping compartment

DPN004924

Connection Locations, Gallery with horizontal-discharge, Front-right facing electrical/piping

compartment

DPN004925

Connection Locations, Gallery with horizontal-discharge, Front-right facing electrical/piping

compartment

Table 5.2 Piping Connection Drawings

5 Piping Requirements

23

Loading...

Loading...