10TA Service Manual

SERVICE OPERATIONS

4/28/14

9-11

Crankcase Heater 100 W (insert type) 12A7509E12 518-0028-01

Oil Pressure safety switch

Sentronic3

Module and Sensor

12A2117A05 585-1076-02

CoreSense Protection Module and Sensor 12A2117A07 943-0109-00

Oil safety – sensor only

For Sentronic, Sentronic 3

or CoreSense

12A2117A0501 998-0162-00

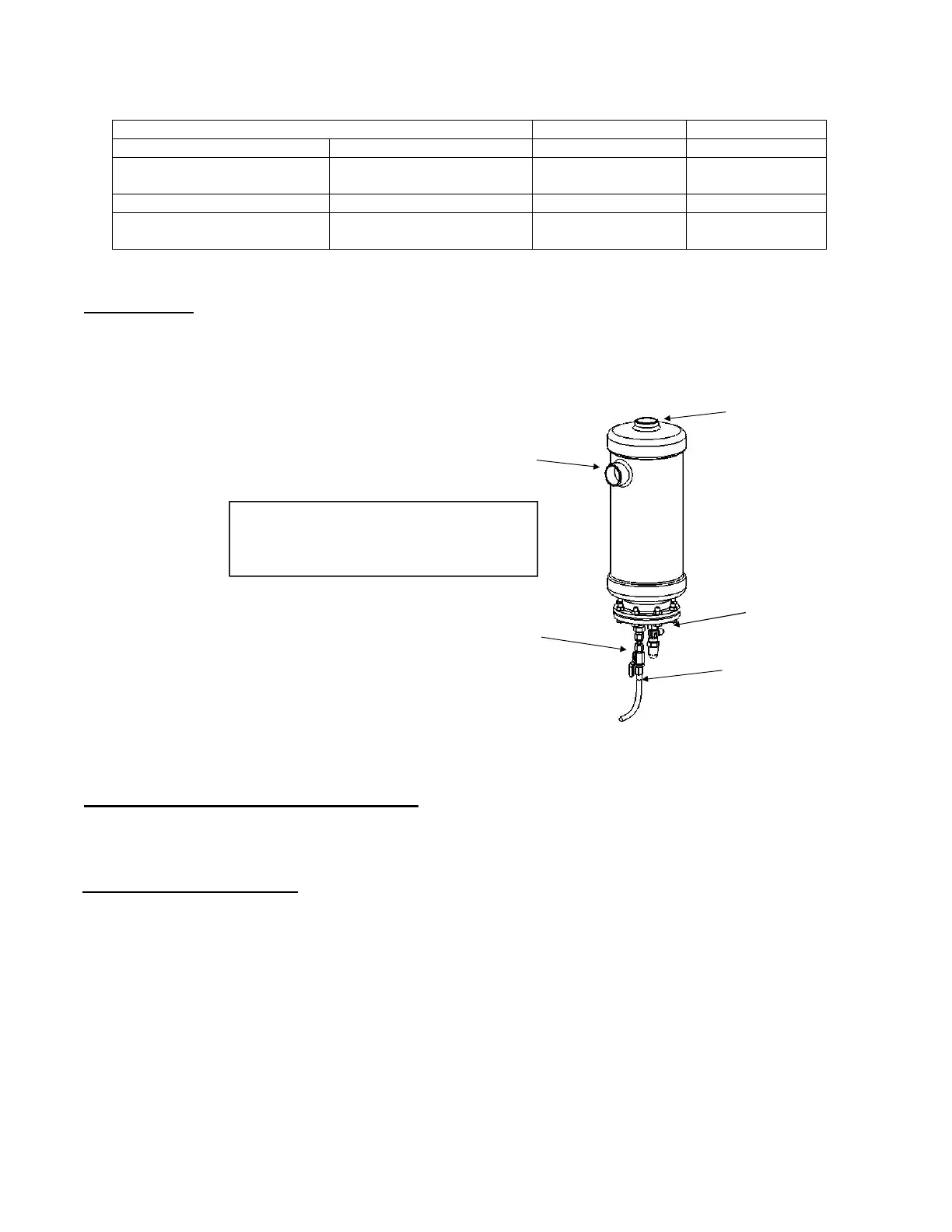

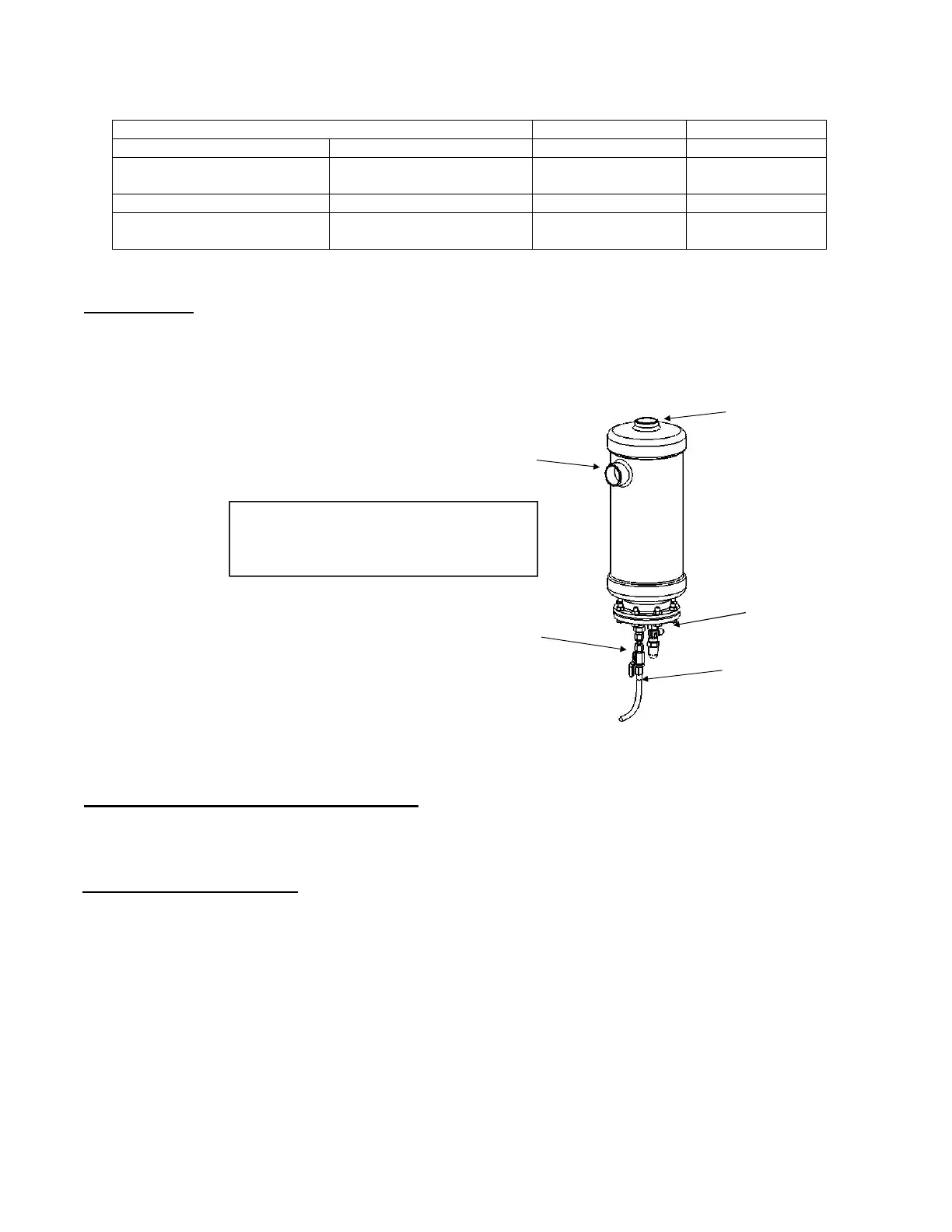

Oil Separator. A helical oil separator is used to separate the oil from the discharge gas and return it

to the compressor. Oil may be drained from the separator through the angle valve located on the

bottom of the oil separator. If necessary, the oil return float mechanism may accessed for cleaning

or replacement by removing the bottom flange. Note: Make sure oil is drained and the pressure

removed from oil separator before disassembling.

FIGURE 9-8

Oil Separator

Compressor Crankcase Heater-100Watt (Part No. 12A7509E12) When electrical power is

supplied to terminals L1, L2 & L3 of the control panel, the crankcase heater is energized when the

machine is not operating. It is de-energized when the compressor contactor is energized.

Control Circuit Protection (Part No. 12A7504E1) The electrical control circuit of the machine is

protected by a 2 Pole, 3A circuit breaker. If the breaker should open, the machine will immediately

stop. Before resetting the breaker, open the disconnect switch to machine and set the

“Clean/Off/Ice” selector switch to the “off” position. If the machine was off for an extended time

the crankcase heater must be energized for a minimum of two hours before restarting the machine.

When ready to restart the machine, set the “Clean/Off/Ice” selector switch to “Ice” and depress the

“Start” button. The machine will start in a harvest, and begin a new freeze cycle upon completion.

Discharge line

from compressor

Oil return line to

compressor

Angle valve with

1/4” access fitting

Oil Separator

Vogt Part #: 12A3025S08

(Add 25 ounces of oil when installing new)

Oil return shutoff valve

Note: Valve may be located at compressor

Loading...

Loading...