SERVICING

REPLACING

THE SEA.WATER

PUMP IMPELLER

The

pump

impeller

is made

of neoprene rubber

and this

can be damaged

in the case

of water

deficiency

caused by, for example,

blocking

of the

sea-water inlet. The

pump

impeller is changed

as

fol

lows:

1.

Close the

bottom cock.

Remove the

cover

from

the

sea-water

pump.

Note the

risk

of water

getting

into

the boat.

With the

help of two

screwdrivers

pullthe

shaft

with the

pump

impeller

out of the

housing as far

as

necessary

in

order

to

reach the

bolt

retaining

the impeller.

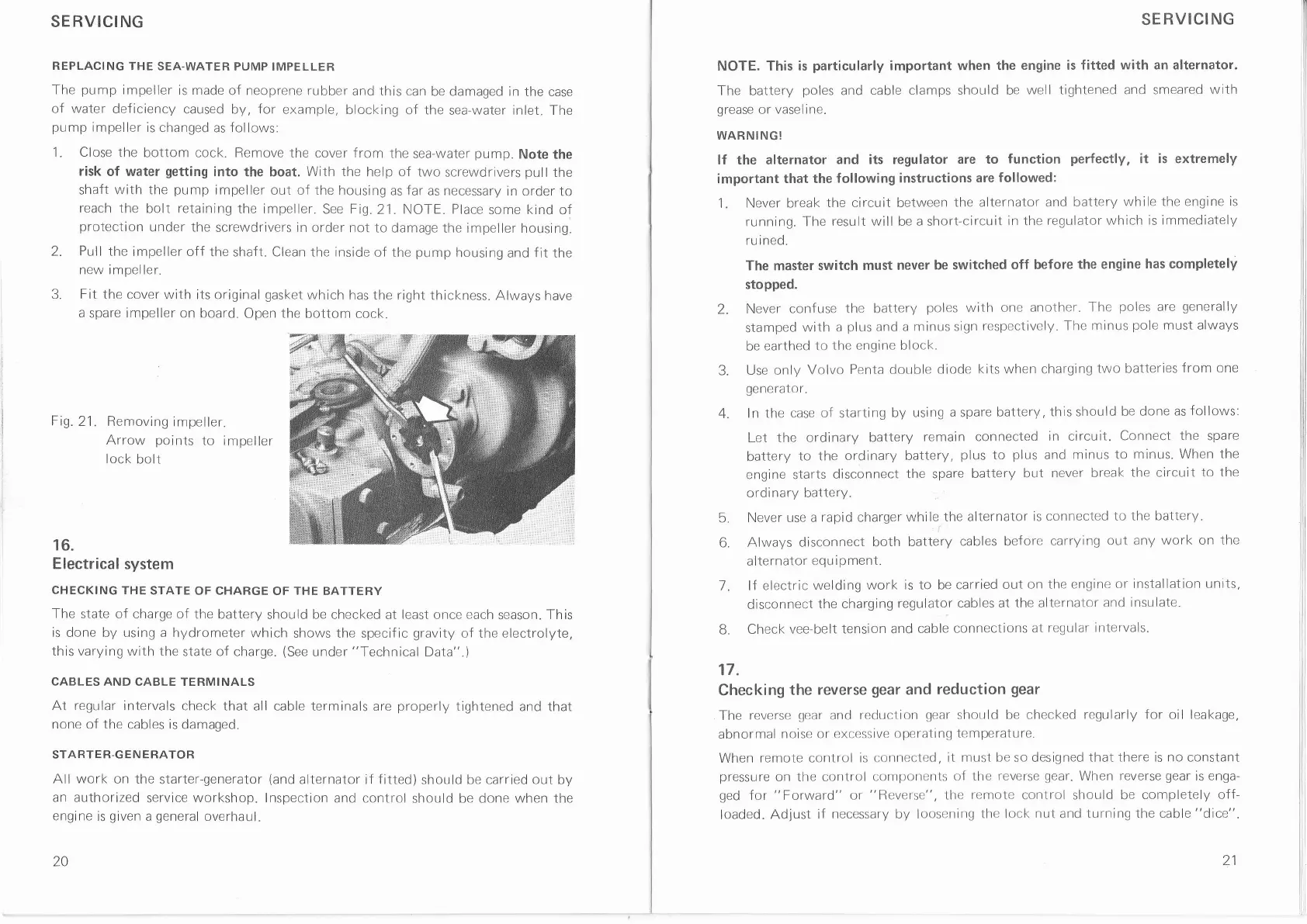

See Fig

21.

NOTE. Place

some

kind

of

protection

under the

screwdrivers in order

not to damage

the impeller

housing.

2.

Pull

the impeller off

the shaft. Clean the inside

of the

pump

housing

and

fit

the

new impeller.

3. Fit the cover

with its original

gasket

which has the right

thickness. Always

have

a

spare impeller on board.

Open the bottom

cock.

Fig.21

.

Removing

impeller.

Arrow

points

to impeller

lock bolt

16.

Electrical

system

CHECKING THE

STATE OF CHARGE

OF THE BATTERY

The

state of charge of

the battery

should be checked at least once each

season.

This

is done by using a

hydrometer which

shows the specific

gravity

of the electrolyte,

this varying

with the state of charge.

(See

under

"Technical

Data".)

CABLES AND CABLE TERMINALS

At regular

intervals check that all

cable terminals are

properly

tightened and that

none

of the

cables

is

damaged.

STARTE

R-GENERATOR

All work on the

starter-generator

(and

alternator

lf

fitted)

should be carried out by

an authorized

service

workshop.

lnspection and control

should be done when the

engine

is

given

a

qeneral

overhaul.

20

SERVICING

NOTE. This is

particularly

important when

the engine is

fitted with an alternator.

The battery

poles

and

cable clamps should be

well tightened and smeared

with

grease

or

vaseline.

WARNING!

lf the alternator

and its regulator are

to

function

perfectly,

it is extremely

important

that the

following instructions

are followed:

1.

Never break

the circuit between

the alternator and

battery

while the engine

is

running. The

result will be a short-circuit

in the

regulatorwhich

is immediately

ru ined.

The master switch

must never

be switched

off before

the engine

has completely

stopped.

2.

Never confuse

the battery

poles

with

one another.

The

poles

are

generally

stamped

with a

plus

and a

minus sign

respectively.

The minus

pole

must always

be

earthed to

the engine block.

3.

Use only

Volvo

Penta double

diode

kits when charging

two

batteries

from one

generator.

4.

ln the case

of

starting

by

using a spare

battery,

this should

be done

as

follows:

Let

the

ordinary battery

remain

connected

in circuit.

Connect

the

spare

battery

to the

ordinary battery,

plus

to

plus

and

minus to

minus. When

the

englne starts

disconnect

the spare

battery

but never

break

the circuit to

the

ordinary batlery.

Never use a

rapid charger while

the alternator

is connected

to

the battery.

Always disconnect

both

battery

cables before

carrying

out any

work on

the

alternator

equipment.

7. lf

electric

welding work

is to be carried

out

on the engine

or installation units,

disconnect

the charging

regulator

cables at

the alternator

and insulate.

8.

Check

vee-belt tension and

cable

connections at

regular intervals.

17.

Ghecking

the

reverse

gear

and

reduction

gear

The

reverse

gear

and

reduction

gear

should be

checked regularly

for

oil leakage,

abnormal

noise or excessive

operatinq temperature.

When

remote

control

is connected,

it must be so designed

that there

is

no

constant

pressure

on the control

components

of the reverse

gear.

When

reverse

gear

is

enga-

ged

for

"Forward"

or

"Reverse",

the

remote

control should be

completely off-

loaded.

Adjust if

necessary by loosening

the lock

nut

and turning

the cable

"dice".

5.

6.

21

Loading...

Loading...