TECHNICAL

DESCRIPTION

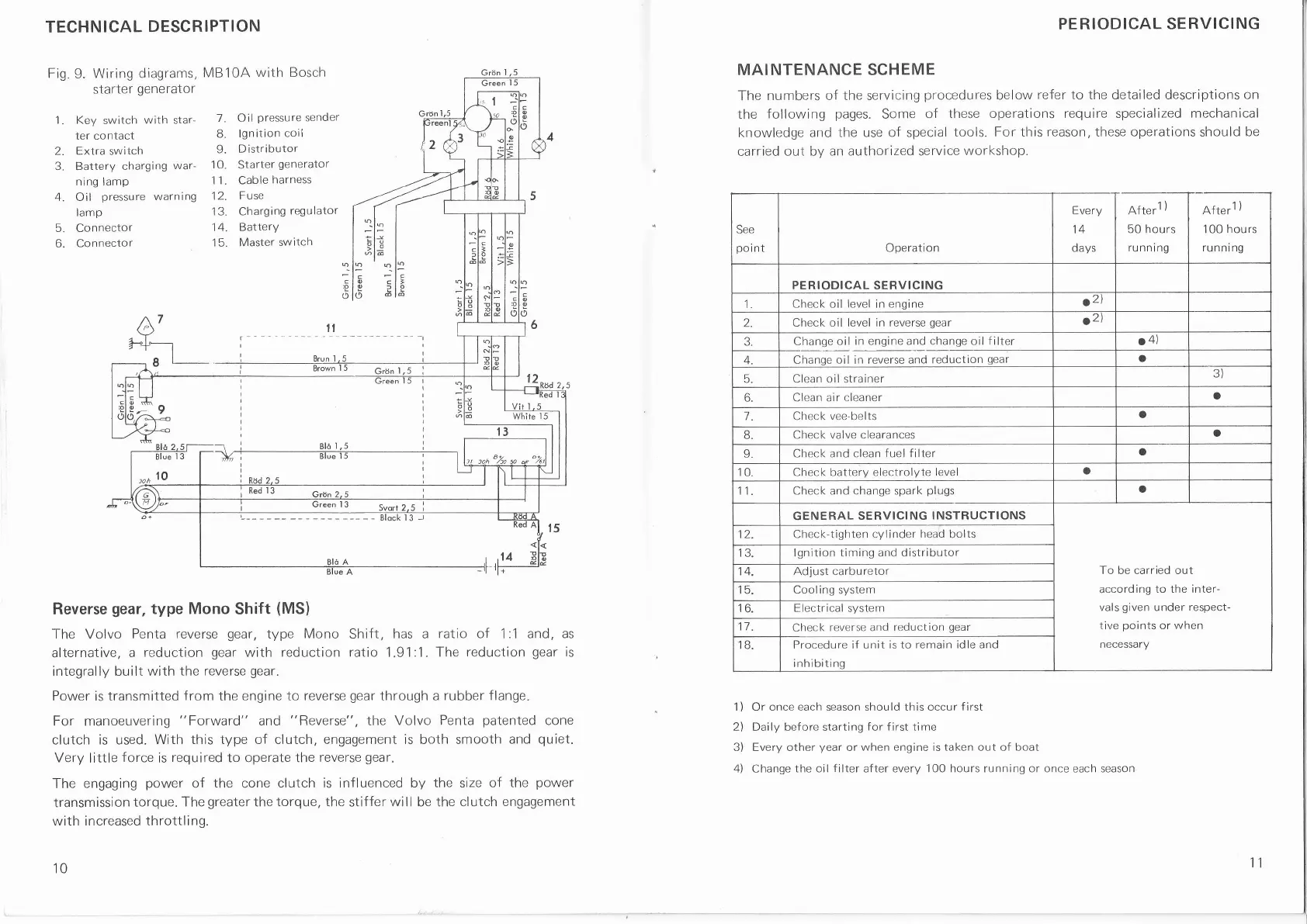

Fig

9.

Wiring diagrams,

MB10A

with Bosch

starter

generator

1.

Key

switch

with star-

7. Oil

pressure

sender

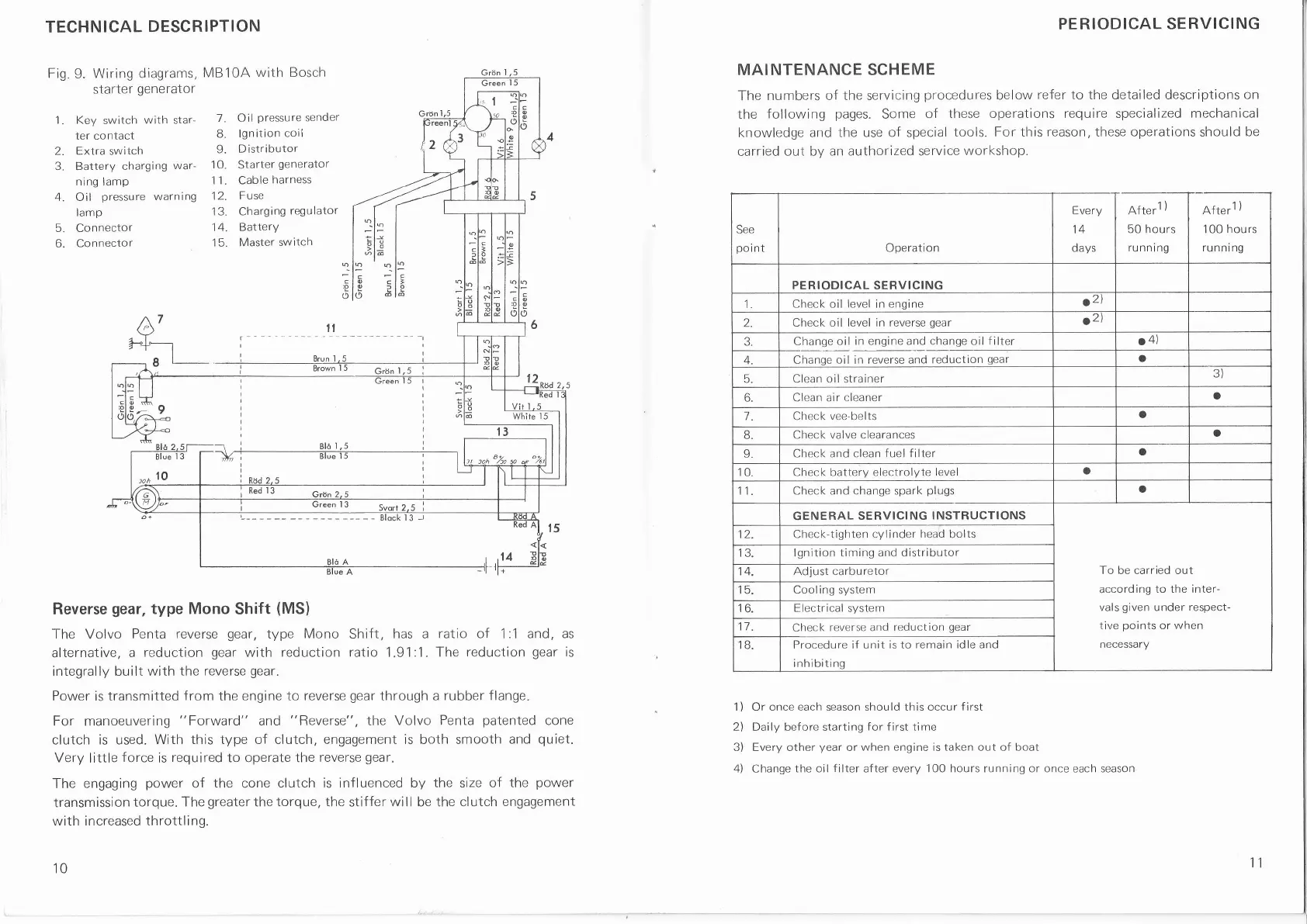

PERIODICAL SERVICING

MAINTENANCE

SCHEME

The

numbers of the servicing

procedures

below

refer to the detailed descriptions

on

the

following

pages.

Some

of these

operations require specialized

mechanical

knowledge and

the use of special

tools. For this

reason,

these

operations

should

be

carried

out

by

an authorized service

workshop.

1

)

Or

once each

season

should this occur

first

2) Daily bef ore starting

for f irst time

3)

Every other

year

or when engine is

taken

out of boat

4) Change

the oil

filter

after every 100 hours running or once each season

ter co

ntact

2. Extra switch

3.

Battery

charging

war

ning lamp

4. Oil

pressure

warning

12.

Fuse

8.

lgnitlon

coil

9. Distributor

1 0.

Starter

generator

1 1. Cable

harness

13. Charging

regulator

14. Battery

15.

Master

switch

lamp

5.

Connector

6. Connector

6

Reverse

gear,

type Mono

Shift

(MS)

The Volvo

Penta reverse

gear,

type Mono Shift, has a

ratio of

i:1

and, as

alternative,

a

reduction

gear

wlth reduction ratio

1.91:1.

The

reduction

gear

is

integrally built with

the reverse

gear.

Power is transmitted

f rom

the

engine to reverse

gear

through a

rubber f

lange.

For manoeuvering

"Forward"

and

"Reverse",

the

Volvo Penta

patented

cone

clutch

is used. With

this type of clutch, engagement is both smooth and

quiet.

Very

little

force

is

required

to operate the

reverse

gear.

The

engaging

power

of the cone clutch

is influenced by the size of

the

power

transmission

torque. The

greater

the torque, the stiffer will be the clutch

engagement

with increased

throttling.

10

See

point

Operation

Every

14

days

Afterl

)

50 hours

ru nni ng

Afterl)

1

0O

hours

runni

ng

PERIODICAL

SERVICING

Check oil

level

in engine

azl

2

Check oil level in reverse

gear

azl

.t- Change oil

in engine and change oil filter

.4)

4.

Chanqe oil in reverse

and reduction

qear

a

5. Clean oil strainer

3)

6.

Clean air cleaner

o

1. Check vee-belts

a

8.

Check valve clearances

o

9.

Check and clean fuel filter

a

'1

0. Check battery

electrolyte

level

o

11

Check

and

chanqe

spark

plugs

a

GENERAL SERVICING

INSTRUCTIONS

To be carried out

according

to the inter-

vals

given

under

respect-

tive

points

or when

necessary

12.

Check-tighten cylinder

head

bolts

13. lgnition timing and distributor

14. Adjust

carburetor

i5. Cooling system

i6.

Electrical

system

11

.

Check

reverse and

reduction

gear

18.

Procedure if unit

is

to

remain idle and

i nhi biti ng

11

Loading...

Loading...