Loading...

Loading...

Do you have a question about the Volvo Penta TAMD162C and is the answer not in the manual?

| Brand | Volvo Penta |

|---|---|

| Model | TAMD162C |

| Category | Engine |

| Language | English |

Details warning symbols and summarizes key safety precautions for engine operation and servicing.

Outlines Pre-Delivery Commissioning (PDC) and First Service inspection requirements.

Describes the basic engine configuration, cooling, and turbocharging systems for these models.

Details the gauges and controls found on the main engine instrument panel, including gauges, switches, and indicators.

Describes the warning lights and their meanings on the engine alarm panel.

Details the specific warning lamps on the extra alarm panel and their corresponding alerts.

Describes the alarm panel and its warning symbols, corresponding to those on the main panel.

Explains the different positions of the key switch and their functions.

Describes single lever and dual lever controls for acceleration and reverse gear maneuvers.

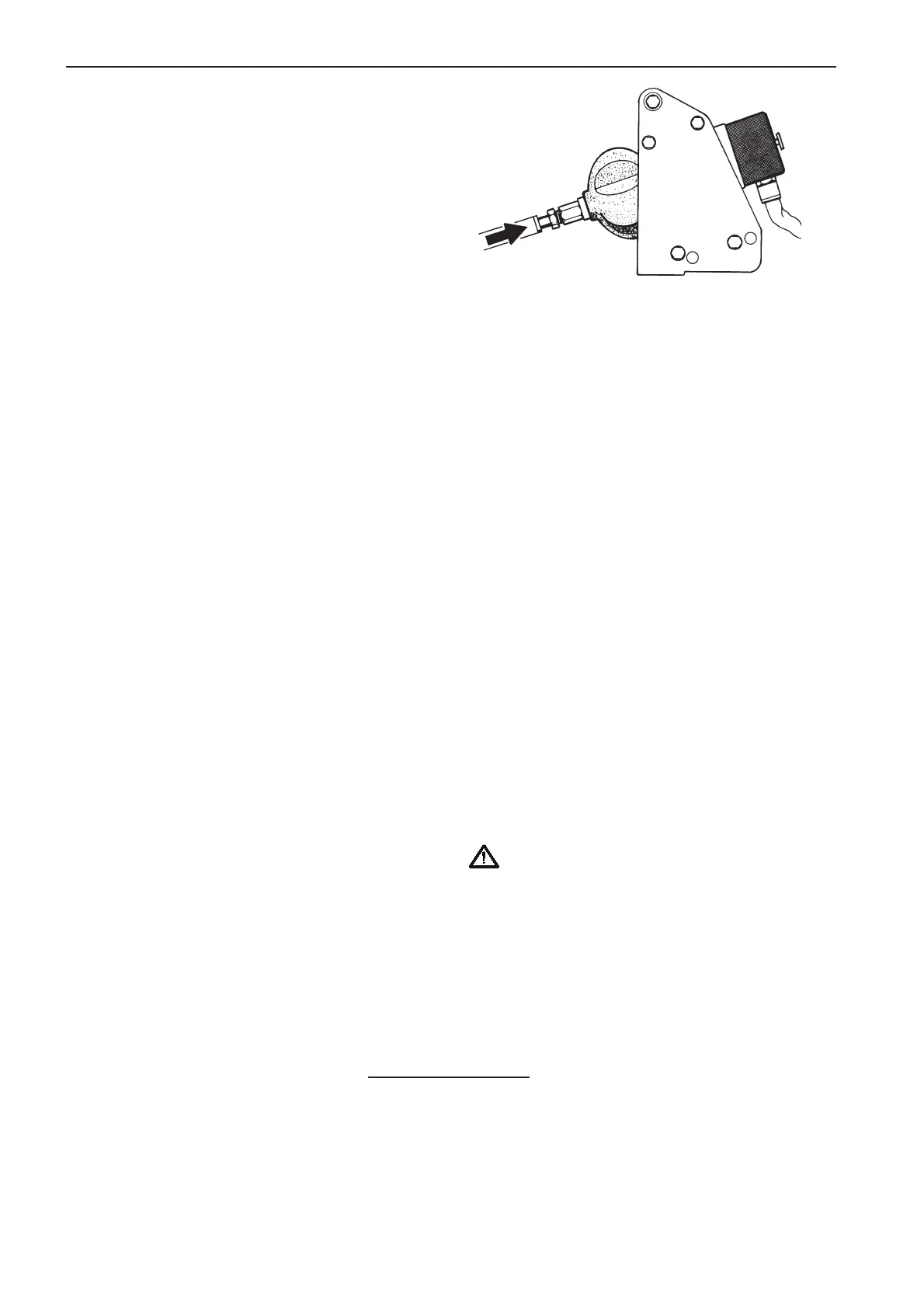

Details the functions and operation of single lever controls, including friction brake and neutral start.

Explains the operation of dual lever controls with separate levers for acceleration and shifting.

Details the required specifications for diesel fuel and the impact of sulfur content.

Specifies the recommended grades and types of lubricating oil for the engine.

Details coolant mixtures, antifreeze needs, and safety precautions for the cooling system.

Specifies the recommended grades of lubricating oil for the reverse gear.

Lists essential checks and actions to perform before starting the engine.

Step-by-step guide for starting the engine using single or dual lever controls.

Guides on how to react when engine alarms are triggered, including causes and actions.

Provides instructions on maneuvering the boat at idling speed and handling the reverse gear.

Details the steps for engaging and disengaging the reverse gear for maneuvering.

Detailed steps for draining the engine's coolant from both freshwater and seawater systems.

Instructions on how to engage the mechanical safety clutch for emergency use.

Steps for engaging the emergency clutch on the Twin Disc MG516 gearbox.

Procedure for engaging the emergency clutch on the MPM IRM 350A gearbox.

Details how to use the emergency stop button on TAMD162C and TAMD163A engines.

Emphasizes the importance of periodic maintenance according to the schedule for reliable operation.

Details oil change intervals based on fuel sulfur content and oil quality.

Instructions for changing the engine oil, including filter replacement and checks.

Procedure for replacing the engine oil and the bypass oil filter.

Steps for replacing engine oil filters while the engine is running.

Steps for changing the oil in the reverse gear, including filter and screen cleaning.

Procedure for replacing oil filters on MPM IRM350 and Twin Disc MG516 reverse gears.

Steps for replacing the fine fuel filters, emphasizing cleanliness and gasket moistening.

Detailed steps for changing the engine oil, including methods for oil removal and refilling.

Procedure for replacing engine oil filters and the bypass filter.

Steps for changing the oil in the reverse gear, including checking the oil level.

Emphasizes turning off the engine and main switches before electrical work.

Provides safety guidelines for battery installation, charging, and handling.

Detailed wiring diagram for the main instrument panel, including component connections and cable colors.

Detailed wiring diagram for the Flying Bridge instrument panel, including component connections.

Detailed wiring diagram for the TAMD162C engine, showing component connections and cable colors.

Detailed wiring diagrams for TAMD162C, TAMD163A, and TAMD163P engines.

Diagnoses and remedies for issues preventing the engine from starting or turning over.

Diagnoses and remedies for a starter motor that turns over slowly.

Diagnoses and remedies for issues causing the engine to not start or run unevenly.

Diagnoses and remedies for engines that start but then stop or run unevenly.

Diagnoses and remedies for engine overheating issues, including causes like low coolant or faulty thermostats.

Diagnoses and remedies for engines failing to reach correct speed at full throttle.

Diagnoses and remedies for engines that continue to run after the stop command.